Precise casting and rapid molding method for multi-cavity automobile exhaust gas treatment system part and detection device for castings

A technology of automobile exhaust and treatment system, applied in casting molding equipment, mold components, cores, etc., can solve the problems of scrap casting, time-consuming, laborious and other problems, and achieve no blockage, accurate angle, and meet the requirements of samples and drawings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

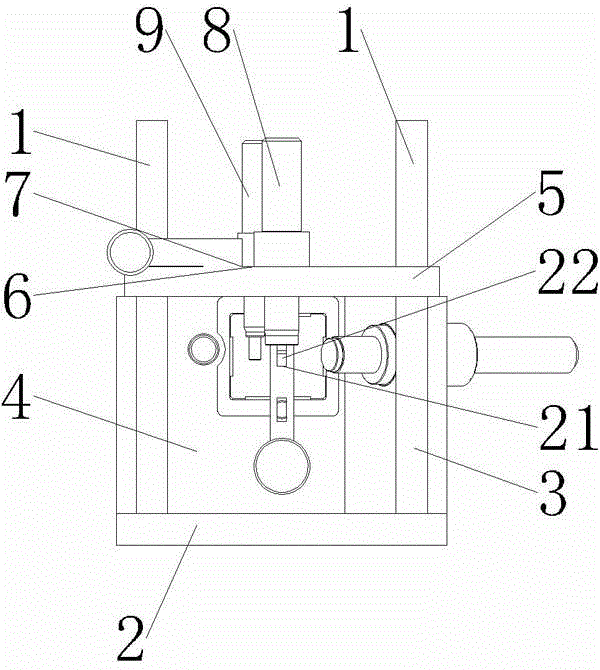

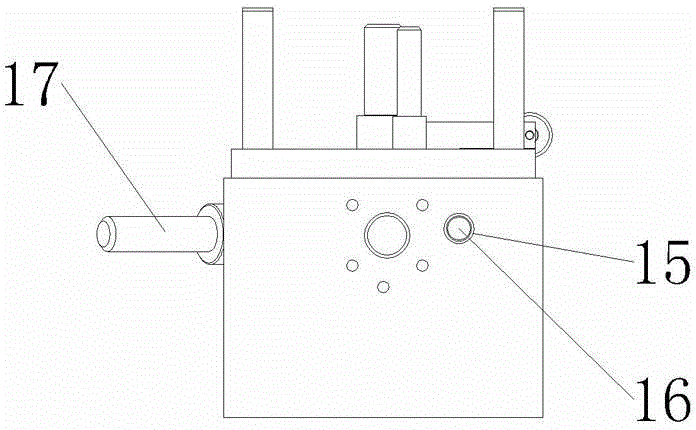

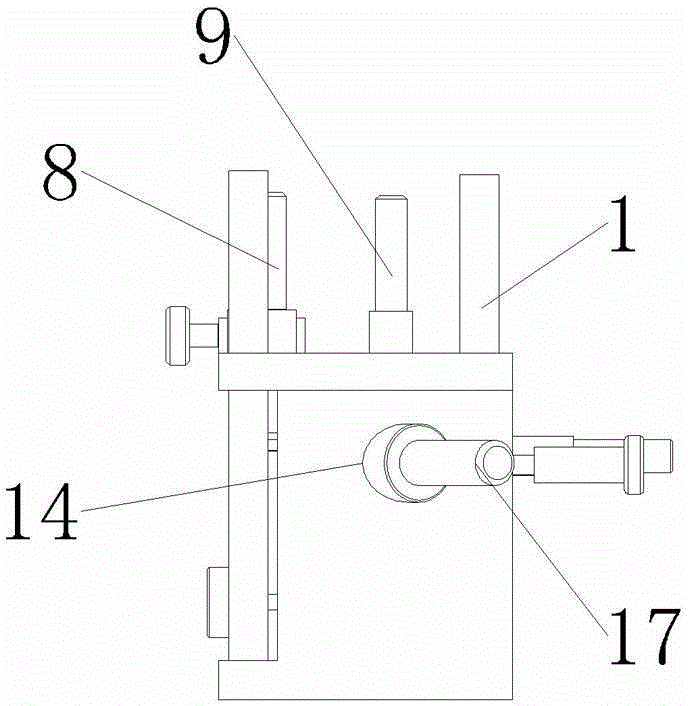

[0024] The present invention discloses a method for precision casting and rapid prototyping of automobile exhaust treatment system components with multi-cavity structure, comprising:

[0025] 1. Model making

[0026] a. The wax-type mold of the main shell is made. The gate of the wax-type mold of the main shell is designed as a top casting process. Area=(1.1-1.2):(1.25-1.35):1; A centrifugal hot top riser is added between the cross gate and the inner gate to facilitate feeding and scum during pouring. The ratio of the section modulus is (1.3-1.8): 1. The inner runner is cylindrical or square, with a length of 3-5mm. The hot top riser is connected with the horizontal gate and the vertical gate. The gate enters the riser along the tangential direction, while the inner gate communicates with the cavity along the bottom surface of the riser; the wax pattern combination is designed as two rows of four groups, that is, four wax patterns. The gate is designed to be upward and obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com