Aluminum alloy side milling process under assistance of ultrasonic longitudinal vibration

A longitudinal vibration and ultrasonic technology, applied in the field of mechanical processing, can solve the problems of immature production and limit the application scope of ultrasonic vibration-assisted milling technology, and achieve the effect of easy to be widely used, mature production technology, and inhibition of sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

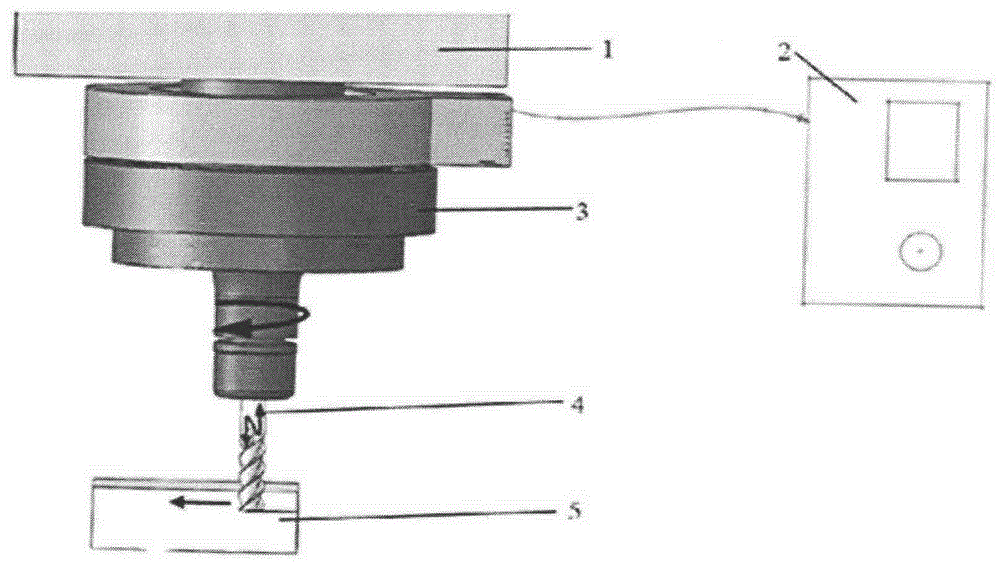

[0015] Such as figure 1 As shown, the device required by the present invention is composed of a common machine tool 1, an ultrasonic generator 2, an ultrasonic longitudinal vibration tool holder 3, a helical end mill 4, and a workpiece 5. Driven by the ultrasonic longitudinal vibration tool holder 3, the helical end mill 4 performs ultrasonic longitudinal vibration. When the tool is side milling, in addition to the rotational motion and the motion in the feed direction, it also undergoes ultrasonic vibration in the axial direction. The process device of the present invention is composed of an ultrasonic generator, an ultrasonic longitudinal vibrating tool holder and a common machine tool. Except that the tool movement mode is different from the common side milling process, other things such as cooling liquid are the same as the common side milling process. The specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com