Laser scribing method and system

A laser scribing and laser technology, which is applied in laser welding equipment, glass manufacturing equipment, glass cutting equipment, etc., can solve problems such as waste products, damage, and irregular reinforcement sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

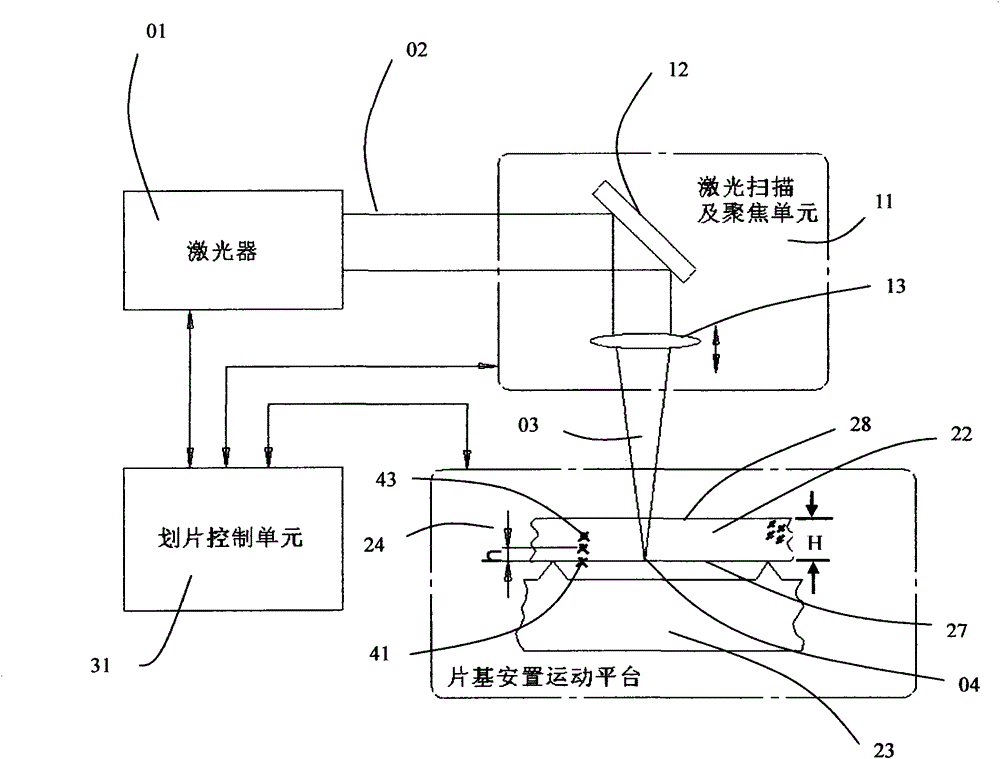

[0025] refer to figure 1 , the corresponding laser scribing device of the present invention includes: a laser 01 , a laser beam scanning and focusing unit 11 , a substrate placement motion platform 21 , and a scribing system control unit 31 . The laser beam scanning and focusing unit 11 is composed of a laser beam turning optical element 12 and a beam focusing optical element 13 . The substrate placement motion platform 21 is made up of the substrate placement platform 23 and other components such as driving and dust removal (not shown in the figure).

[0026] Under the premise of confirming that the laser 01 is in the off state, the substrate 22 to be scribed is placed on the workpiece placement platform 23 in the upward direction of the upper surface 28 processed with various functional structures on the substrate, and the positioning edge of the substrate should be Close to the positioning edge on the workpiece placement platform ( figure 1 Not marked in ), so that the X ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com