Neodymium niobate ceramic having improved microwave dielectric characteristic by substituting neodymium ions with lanthanum ions

A microwave dielectric and neodymium ion technology is applied in the field of neodymium niobate ceramics and its preparation, and achieves the effects of simple preparation process, environmental protection, and uniform and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

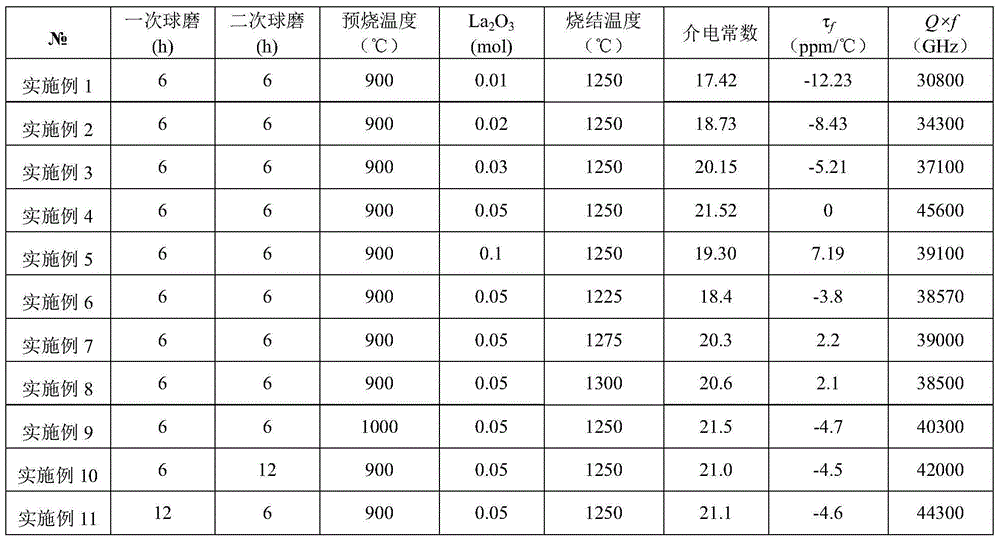

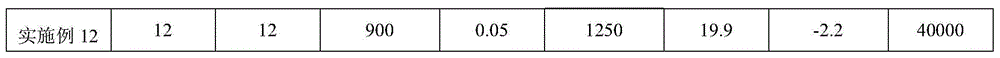

Examples

Embodiment 1

[0023] 1. According to the microwave dielectric ceramic composition (Nd 1-x La x )NbO 4 (x=0.01), weigh Nd 2 O 3 -5.5318g, La 2 O 3 -0.0541g, Nb 2 O 5 -4.4141g ingredients, 10g in total; put the mixed powder into a polyester tank, add 160ml deionized water and 150g zirconium balls, and then ball mill on a planetary ball mill for 6 hours, the ball mill speed is 1000 rpm;

[0024] 2. Place the ball-milled raw materials in a drying box, dry at 120°C and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0025] 3. Calcining the powder at 900°C for 4 hours;

[0026] 4. Put the calcined powder into a polyester tank, ball mill it for 6 hours, and dry it after discharging, and pass through a 40-mesh sieve; then add 6% by weight paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then use a powder tableting machine to compress a body with a diameter of 10mm and a thickness of 5mm at a pressure of 7MPa;

[0027] 5. The green body is sintered at 12...

Embodiment 2

[0030] 1. According to the microwave dielectric ceramic composition (Nd 1-x La x )NbO 4 (x=0.02), weigh Nd 2 O 3 -5.4769g, La 2 O 3 -0.1082g, Nb 2 O 5 -4.4149g ingredients, 10g in total; put the mixed powder into a polyester tank, add 160ml deionized water and 150g zirconium balls, and then ball mill on a planetary ball mill for 6 hours, the ball mill speed is 1000 rpm;

[0031] 2. Place the ball-milled raw materials in a drying box, dry at 120°C and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0032] 3. Calcining the powder at 900°C for 4 hours;

[0033] 4. Put the calcined powder into a polyester tank, ball mill it for 6 hours, and dry it after discharging, and pass through a 40-mesh sieve; then add 6% by weight paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then use a powder tableting machine to compress a body with a diameter of 10mm and a thickness of 5mm at a pressure of 7MPa;

[0034] 5. The green body is sintered at 12...

Embodiment 3

[0037] 1. According to the microwave dielectric ceramic composition (Nd 1-x La x )NbO 4 (x=0.03), weigh Nd 2 O 3 -5.4220g, La 2 O 3 -0.1624g, Nb 2 O 5 -4.4156g of ingredients, 10g in total; add the mixed powder to a polyester tank, add 160ml of deionized water and 150g of zirconium balls, and then ball mill on a planetary ball mill for 6 hours at a speed of 1000 rpm;

[0038] 2. Place the ball-milled raw materials in a drying box, dry at 120°C and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0039] 3. Calcining the powder at 900°C for 4 hours;

[0040] 4. Put the calcined powder into a polyester tank, ball mill it for 6 hours, and dry it after discharging, and pass through a 40-mesh sieve; then add 6% by weight paraffin wax as a binder for granulation, and Pass through an 80-mesh sieve; then use a powder tableting machine to compress a body with a diameter of 10mm and a thickness of 5mm at a pressure of 7MPa;

[0041] 5. The green body is sintered at 1250°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com