Method for preparing naringenin ultrafine particle by using supercritical compressed fluid anti-solvent precipitation process

A technology of anti-solvent precipitation and compressed fluid, which is applied in organic chemistry, bulk chemical production, etc., can solve the problems of low bioavailability, poor oral absorption, slow dissolution rate, etc., and achieve low solvent residue, convenient operation, and high yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

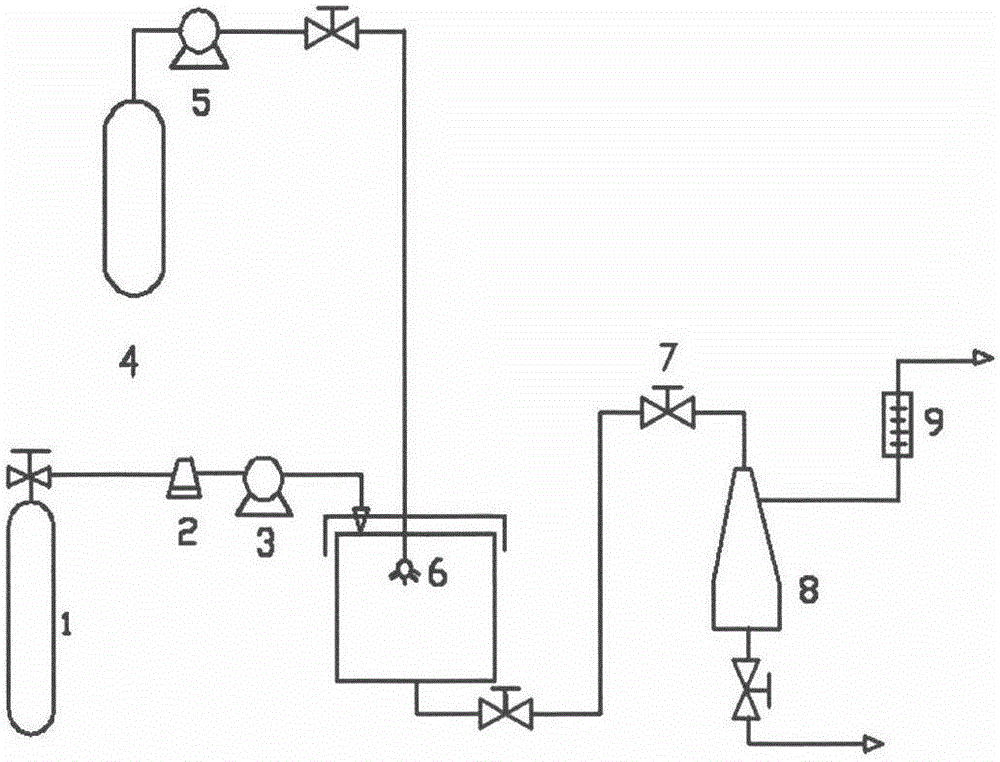

[0022] figure 1 It is an equipment diagram for implementing the method of the present invention. The device mainly includes a carbon dioxide delivery system, a solution delivery system and an autoclave. The main implementation process is: check the airtightness of the system, open the top CO2 2 Open the inlet valve and start the heater of the crystallization kettle. After the inside and outside of the kettle reach the predetermined temperature, the CO in the cylinder 2 Through the low-temperature constant temperature tank and high-pressure pump, it is passed into the crystallization kettle from the top of the kettle. After the temperature and pressure in the kettle are stabilized, open the CO2 at the bottom of the kettle. 2 outlet valve, and adjust the trim valve to a predetermined volume flow. After the system is stable, the prepared solution is sprayed into the crystallization kettle from the top of the kettle through the nozzle by the high-pressure infusion pump at a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com