Preparation method of flame retardant cyke tris(dimethyl-1,3-dihalopropoxysilicate) ester compound

A technology of dihalopropoxysilicic acid and dimethyldichlorosilane, applied in the field of flame retardant plasticizers, can solve problems such as limitations, and achieve the effects of large molecular weight, good compatibility and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

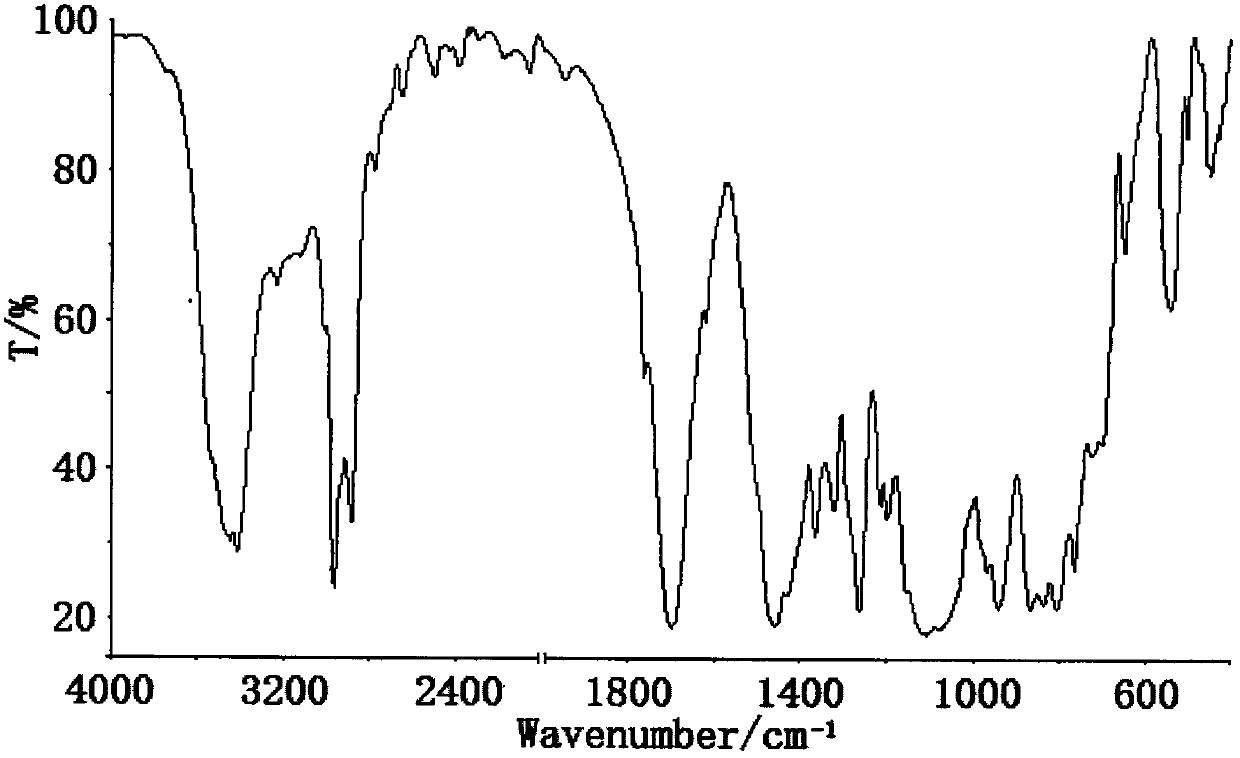

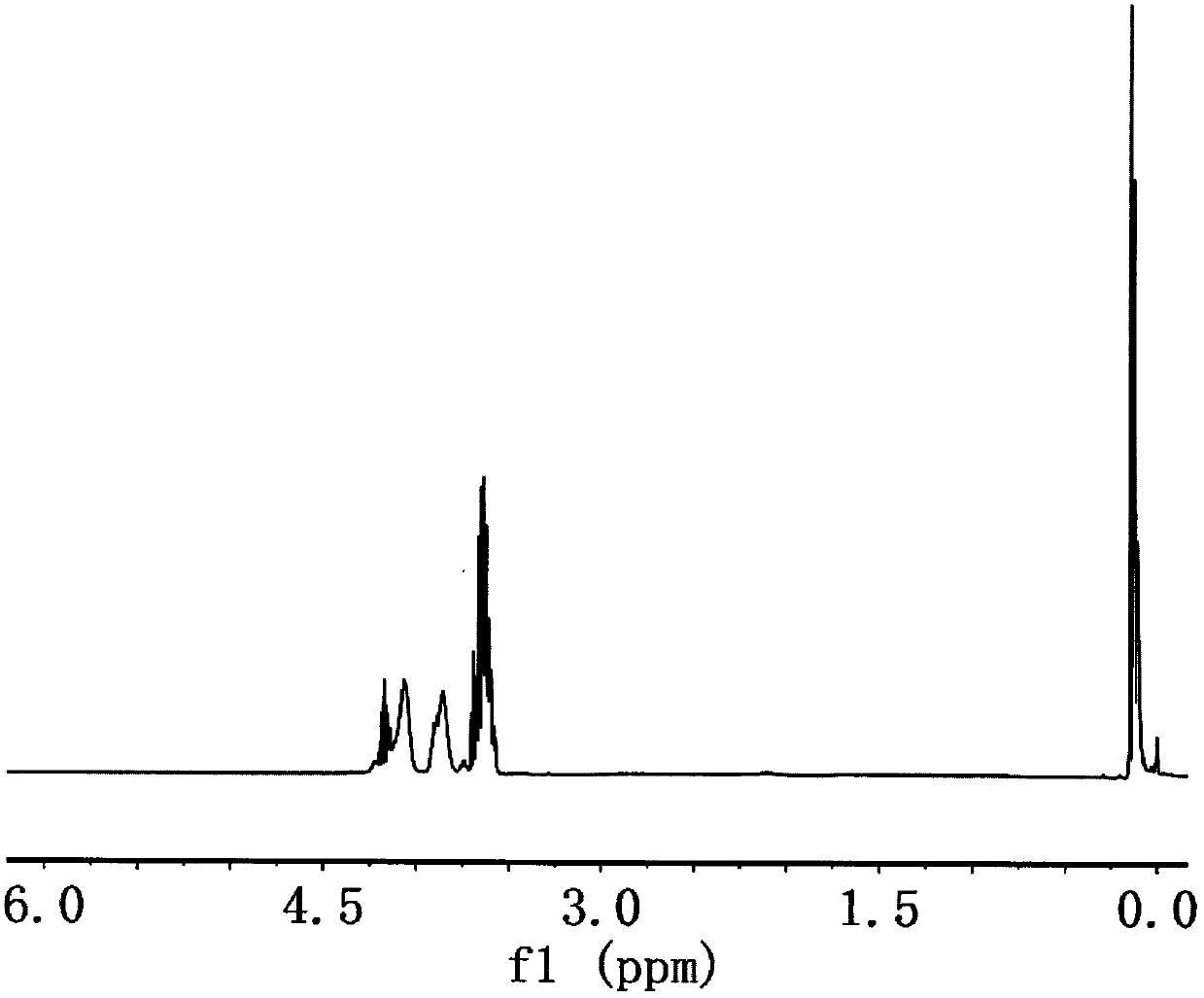

Embodiment 1

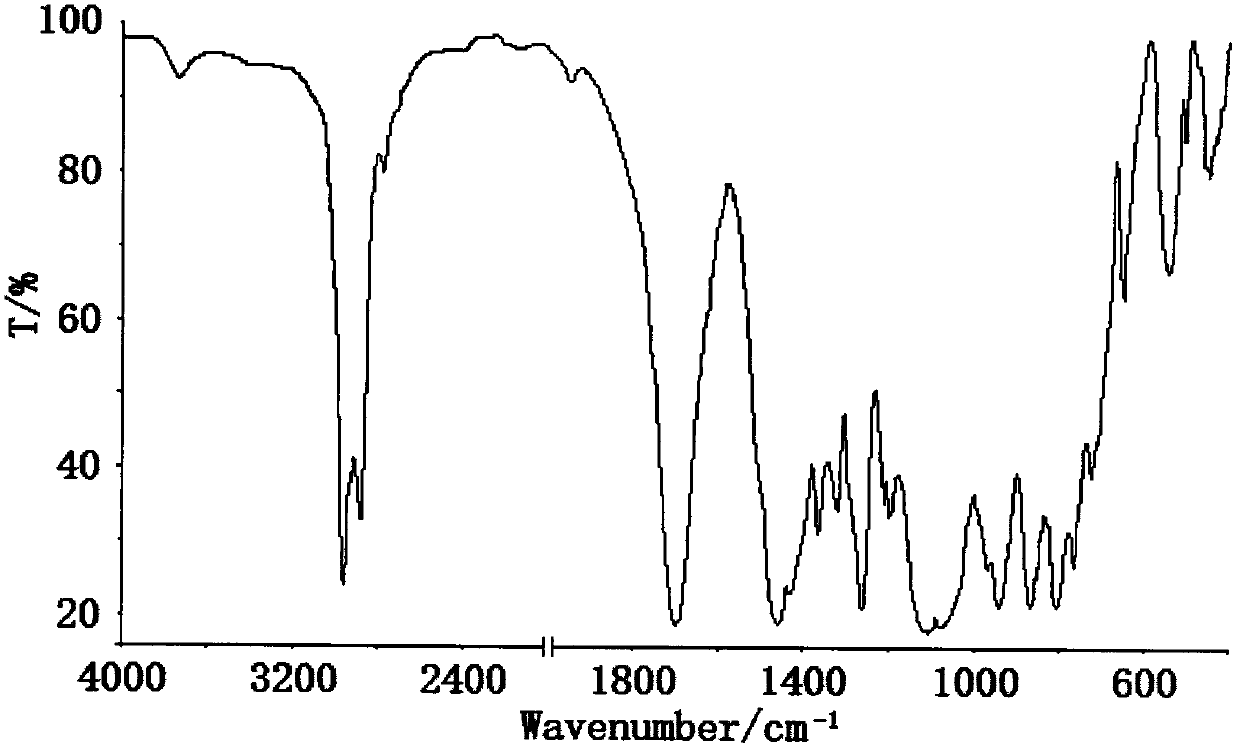

[0036] Embodiment 1 In the 250ml four-necked bottle that stirrer, thermometer and condensation tube are equipped with, and drying tube and hydrogen chloride absorption device are equipped with at the top of condensation tube, replace the air in the bottle with nitrogen, add 8.74g (0.0333mol ) Trihydroxyethylisocyanurate and 100ml dioxane, add 12.91g (0.1mol) dimethyldichlorosilane, heat up to 70°C, keep warm for 5h; after the HCl gas is released, cool down to 30°C Below ℃, add 12.9g (0.1mol) 1,3-dichloro-2-propanol dropwise, control the reaction temperature not higher than 40℃ with the dropping speed, raise the temperature to 90℃ after dropping, keep the reaction for 8h; wait for HCl gas After the release, add 0.3g of melamine, adjust the pH of the system to 5-6, filter with suction, distill the filtrate under reduced pressure to remove the solvent and a small amount of low boiling point substances, then add 80ml of petroleum ether, stir for 0.5h, stand still, and separate the ...

Embodiment 2

[0037] Embodiment 2 In the 250ml four-necked bottle that stirrer, thermometer and condensation tube are equipped with, and drying tube and hydrogen chloride absorption device are equipped with on the top of condensation tube, replace the air in the bottle with nitrogen, add 8.74g (0.0333mol ) trihydroxyethyl isocyanurate and 140ml tetrahydrofuran, add 12.91g (0.1mol) dimethyldichlorosilane, heat up to 50°C, keep warm for 9 hours; after the HCl gas is released, cool down to below 30°C, Add 13.76g (0.1067mol) 1,3-dichloro-2-propanol dropwise, control the reaction temperature not higher than 40°C at the rate of addition, raise the temperature to 60°C after dropping, and keep it warm for 12 hours; after the HCl gas is released , add 0.5g melamine, adjust the pH of the system to 5~6, filter with suction, distill the filtrate under reduced pressure to remove solvent, excess 1,3-dichloro-2-propanol and a small amount of low boiling point substances, then add 100ml petroleum ether, sti...

Embodiment 3

[0038] Embodiment 3 In the 250ml four-necked bottle that stirrer, thermometer and condensation tube are housed, and drying tube and hydrogen chloride absorption device are equipped with at the top of condensation tube, replace the air in the bottle with nitrogen, add 8.74g (0.0333mol ) trihydroxyethyl isocyanurate and 100ml diethylene glycol dimethyl ether, add 12.91g (0.1mol) dimethyldichlorosilane, heat up to 55°C, and keep it warm for 8 hours; after the HCl gas is released, Cool down to below 30°C, add 15.05g (0.1167mol) of 1,3-dichloro-2-propanol dropwise, control the reaction temperature not higher than 40°C at the rate of addition, raise the temperature to 110°C after dropping, and keep warm for 6 hours; After the HCl gas is released, add 1 g of melamine, adjust the pH of the system to 5-6, filter with suction, and distill the filtrate under reduced pressure to remove the solvent, excess 1,3-dichloro-2-propanol and a small amount of low boiling point substances, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com