A device and method for forming caking pulverized coal and producing dry distillation products

A cohesive and dry distillation technology, which is applied in the direction of special dry distillation, indirect heating dry distillation, coke oven heating, etc., can solve the problems of not being able to achieve dry distillation molding at the same time, obtain high-yield and high-quality oil and gas products, and achieve increased tar production. Yield and quality, high yield preparation, reducing the effect of secondary cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

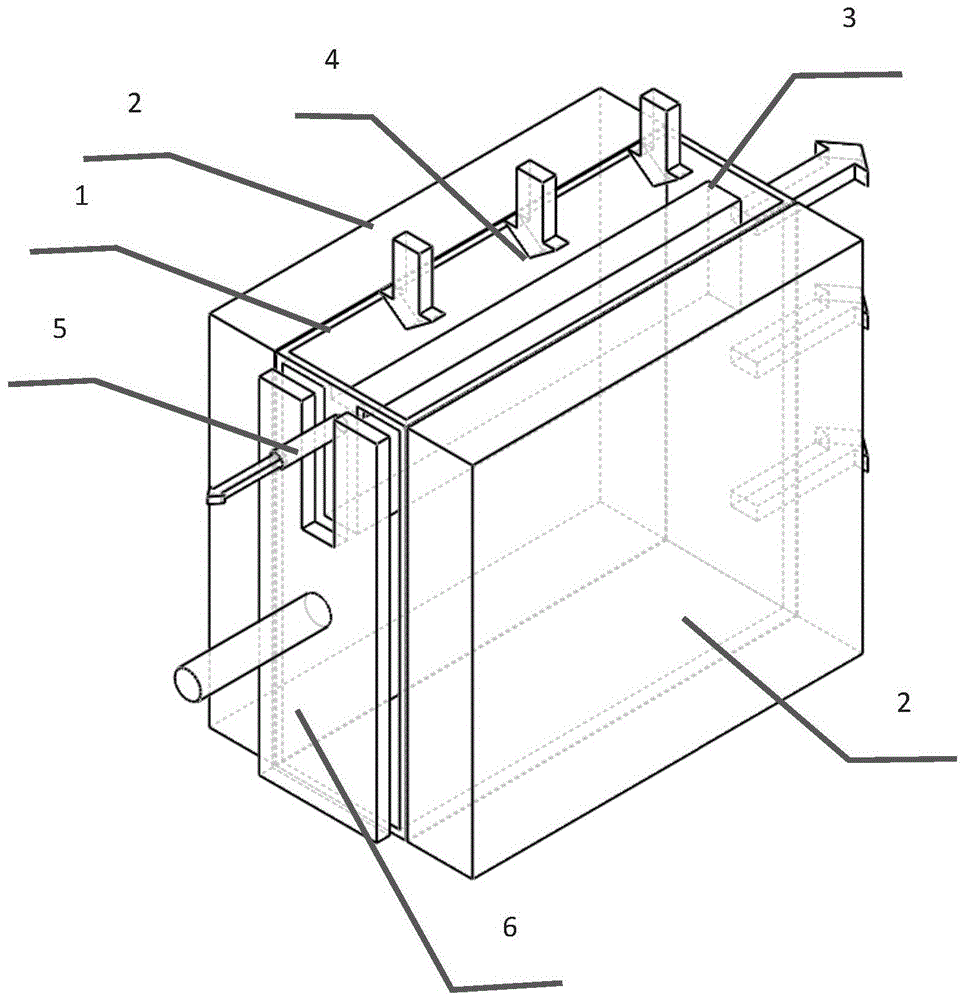

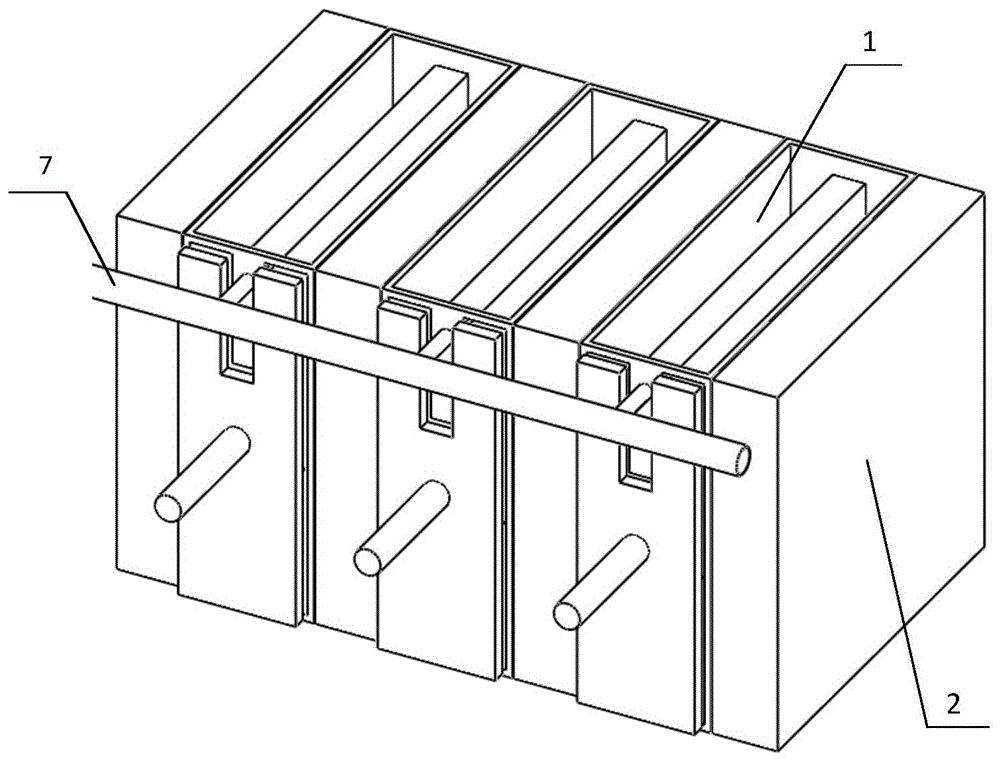

[0027] The present invention will be further described in detail with the accompanying drawings and specific embodiments.

[0028] like figure 1 As shown, a device for the production of cohesive pulverized coal molding and carbonization products, the device includes a carbonization reactor 1, gas combustion heating chambers 2 are arranged on the left and right sides of the carbonization reactor 1, and the A hollow channel 3 with an open bottom is provided in the upper part of the retort forming reactor 1, and the hollow channel 3 communicates with the retort gas phase product discharge pipe 5;

[0029] The device also includes a coke pusher 6, the coke pusher 6 is the movable front side of the retort molding reactor 1, the coke pusher 6 can move along the hollow channel 3 and is used to push out the coke pusher 6 into the retort molding reactor 1 The molding semi-focus.

[0030] The focus pusher 6 is in a "concave" shape suitable for the hollow channel 3 .

[0031] like f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com