A permanently modified desulfurized gypsum composite thermal insulation formwork and its manufacturing method

A desulfurized gypsum and composite thermal insulation technology, applied in chemical instruments and methods, synthetic resin layered products, hydraulic material layered products, etc., can solve the problems of long cement hydration cycle, large space occupation and high manufacturing cost, Achieve the effect of meeting the building energy saving rate, low cost and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the present invention, the following examples are provided.

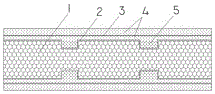

[0034] A permanently modified desulfurized gypsum composite thermal insulation formwork, characterized in that the polyurethane board is prepared into a rectangular groove 1 in the vertical and horizontal directions by a slotting machine, and an interface agent 2 is applied on the outside, and then a modified desulfurized gypsum slurry 4 is applied on the outside, and the modified desulfurization The reinforcing material 3 is filled in the middle of the gypsum slurry; the interface agent is epoxy resin; the reinforcing material filled in the middle of the modified desulfurized gypsum slurry is alkali-resistant glass fiber mesh cloth;

[0035] The modified desulfurized gypsum slurry adopts calcined desulfurized gypsum (mainly composed of calcium sulfate hemihydrate), mineral activator, lightweight thermal insulation aggregate, redispersible latex powder, water reducing agent, composite wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com