A kind of marine incinerator treatment system

A treatment system and incinerator technology, applied in the field of shipbuilding technology and incineration, can solve the problems of low loading rate, many ancillary equipment, and difficulty in popularization, so as to improve incineration treatment capacity, reduce treatment capacity, and prevent environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

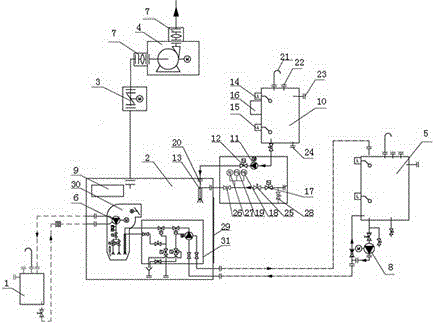

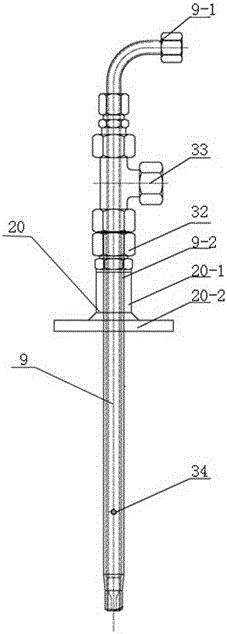

[0017] A kind of marine incinerator processing system provided by this embodiment, such as figure 2 As shown, it includes a diesel cabinet 1, an incinerator 2, a flue gas damper 3, a flue gas fan 4, and a sludge tank 5. The diesel cabinet 1 is connected to the diesel input port of the incinerator 2 through a delivery pump 6, and the flue gas outlet of the incinerator 2 The expansion joint 7 of the flue gas fan 4 is connected through the flue gas damper 3, and the sludge sludge inlet of the incinerator 2 is connected to the sludge sludge tank 5 through a circulation pump 8. The electrical control box 9 is installed on the incinerator 2, and a waste water storage cabinet 10 is also included. The waste water storage cabinet 10 is connected to the water inlet of the incinerator 2 through the waste water metering pump 11, the first control valve 12 and the waste water injection device 13. The upper and lower parts of the waste water storage cabinet 10 are respectively equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com