Direct current driving and active temperature control system for high-frequency pulse tube refrigerator and design method

A high-frequency pulse, DC-driven technology, applied in the fields of refrigeration and cryogenic engineering and physical electronics, can solve the problems of the performance impact and fluctuation of the cooled device, achieve stable regulation, efficient conversion, improve energy utilization efficiency and control. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

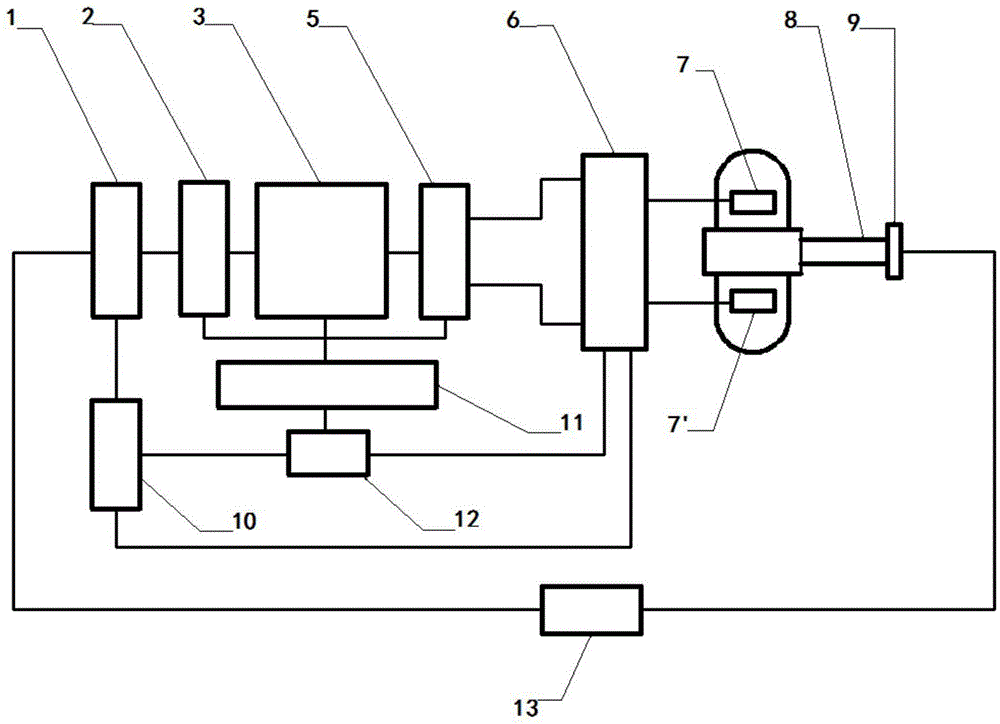

[0029] figure 1 It is a schematic diagram of the DC drive and active temperature control system of the invented high-frequency pulse tube refrigerator;

[0030] The invented high-frequency pulse tube refrigerator DC drive and active feedback temperature control system includes a temperature signal operational amplifier module 1, an analog-to-digital signal conversion module 2, a PID control module 3, a digital signal processor 3, and an H-bridge power amplifier module 6 , DC-DC conversion module one 10, DC-DC conversion module two 11 and thermocouple temperature measurement bridge module 13, it is characterized in that:

[0031] The external DC bus 12 is connected to the H-bridge power amplifier module 6 for power supply, the DC-DC conversion module 10 is connected to the temperature signal operational amplifier module 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com