Double-arc annular random packing

A random packing and ring-shaped technology, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of limited mass transfer efficiency, small lateral flux on the surrounding wall, large flux, etc. problems, to achieve the effect of uniform distribution of gas and liquid, regular arrangement and large flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to clearly understand the structure and innovation essence of the random packing of the present invention, the embodiments of the random packing of the present invention will be described in detail below with reference to the accompanying drawings.

[0013] Aiming at the problems existing in various traditional packings, the purpose of the present invention is to propose a double-arc annular packing with larger flux, higher mass transfer efficiency and lower pressure drop.

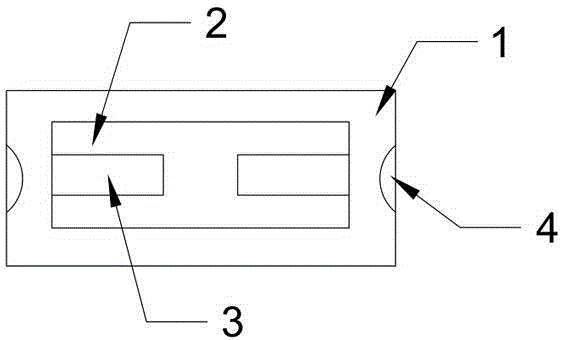

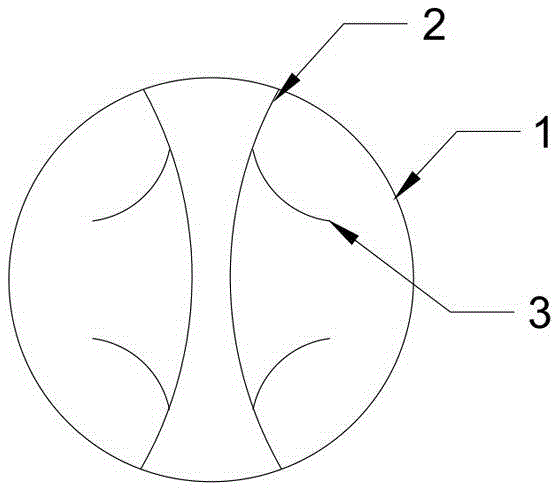

[0014] Such as figure 1 and figure 2 As shown, this kind of double-arc annular random packing is a metal flat ring rolled in one piece, which can be rolled with a thin steel strip with a thickness of less than 1mm. In terms of its characteristic structure, the metal flat ring is provided with a rectangular window and an inwardly curved rib 2 connected to the two short sides of the rectangular window on the peripheral wall 1 of the metal flat ring. A rectangular micro-window, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com