DMF (dimethyl formamide) wastewater treatment device and method

A waste water treatment and waste water technology, which is applied in natural water body treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large space occupation, poor energy saving effect, high equipment cost, etc., and achieve a reduction in land occupation area, reduce tower equipment, and reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

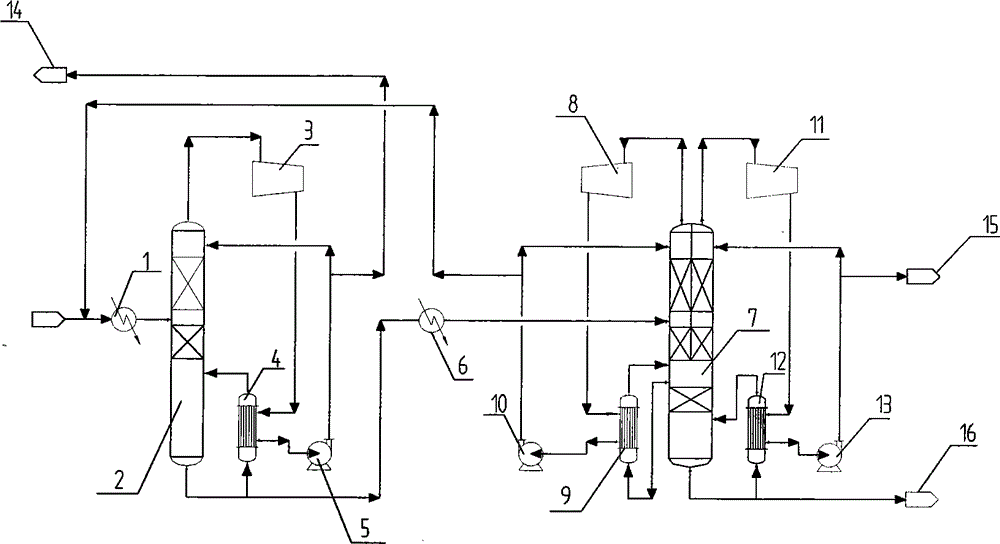

Embodiment 1

[0032]Dividing Wall Column (DWC for short) is a vertical wall installed in the rectification column, and the vertical wall can also be extended to the top or bottom of the column. The two parts of the DWC column separated by the dividing wall can have a common Rectification section or stripping section, or both common rectification section and stripping section. The DWC tower is a thermodynamically ideal system structure. When separating the three-component mixture, the same number of theoretical plates is used to complete the same separation task. The DWC tower requires less reboiling heat and condensation than the traditional two-tower process. quantity. For some given materials, the reflux ratio of the dividing wall distillation column is smaller than that of the conventional distillation column, so the operating capacity is increased, the energy saving can reach more than 60%, and the equipment investment may be saved by 30%. DWC tower can be widely used in petroleum refi...

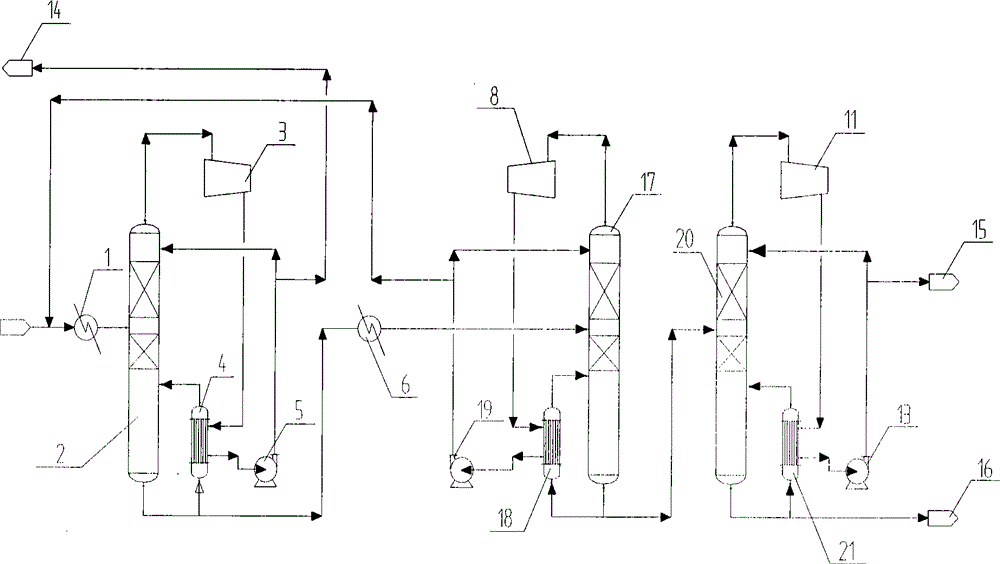

Embodiment 2

[0048] figure 2 Shown is a schematic structural diagram of the DMF wastewater treatment device in Example 2 of the present invention.

[0049] Such as figure 2 Shown, a kind of DMF wastewater treatment device provided by the present invention comprises waste water preheater 1, vacuum distillation tower 2, steam compressor 3, vacuum distillation tower reboiler 4, vacuum distillation tower reflux Pump 5, intermediate vaporizer 6, water removal tower 17, DMF rectification tower 20, intermediate steam compressor 8, water removal tower reboiler 18, water removal tower condensate return pump 19, DMF compressor 11, DMF rectification tower reboiler 21 and DMF delivery pump 13;

[0050] The waste water preheater 1 is connected to the vacuum rectification tower 2, and the top of the vacuum rectification tower 2 is connected to the water vapor compressor 3, and the water vapor compressor 3 is connected to the vacuum rectification tower 2 through the vacuum rectification tower reboile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com