Electrochemical wastewater treatment method for removing salts and refractory organic matters synchronously

A refractory organic matter and electrochemical technology, which is applied in the field of wastewater treatment containing salt and refractory organic matter, can solve the problems that electrochemical oxidation technology cannot desalinate and effectively remove organic matter, so as to save space, reduce energy consumption, and broaden the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

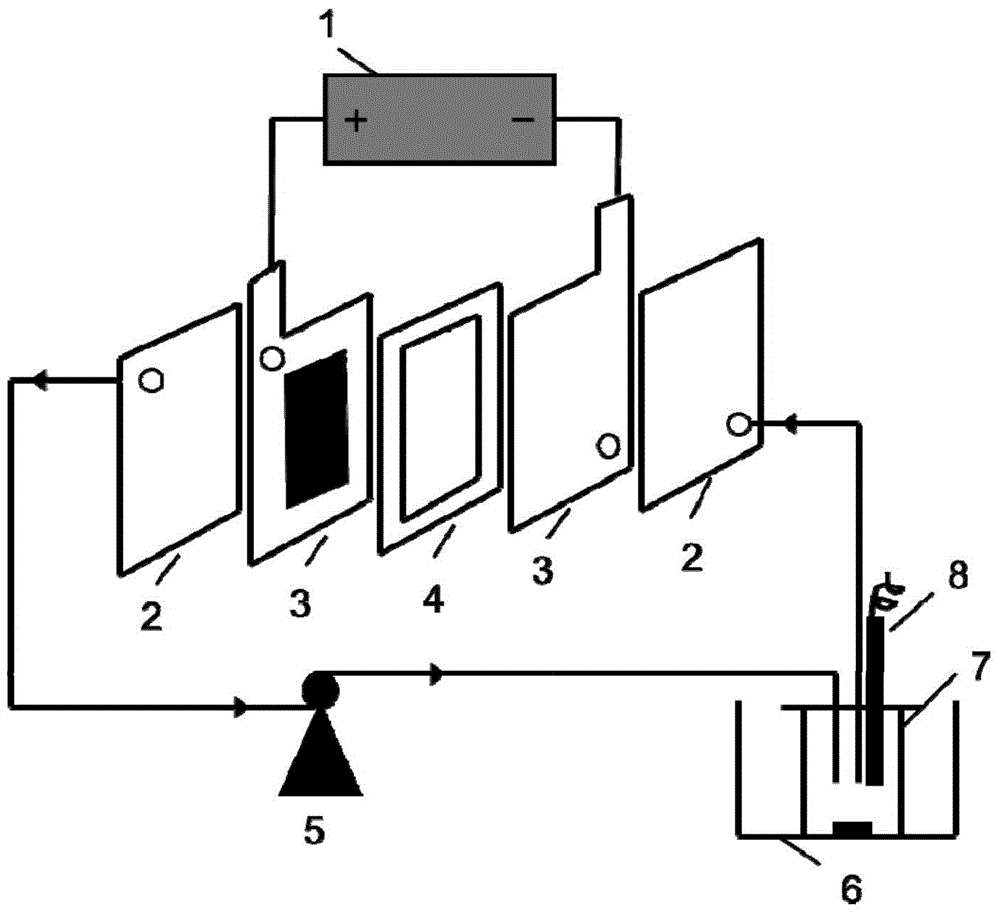

Image

Examples

Embodiment 1

[0040] The method of the invention treats the waste water containing NaCl and phenol.

[0041] Prepare carbon airgel / polyvinylidene fluoride electrode as the positive and negative electrodes of the electrochemical wastewater treatment unit, the positive and negative electrodes are the same, wherein the carbon airgel mass fraction is 95%, polyvinylidene fluoride 5%, no metal oxide The total mass of the electrode is 1g. The solution in the storage tank was aerated with oxygen at 500ml / min without adding Fe ions. 100ml of wastewater containing 0.1g / L NaCl and 1mmol / L phenol was circulated through the electrochemical treatment unit at a flow rate of 40ml / min, the wastewater temperature was 10°C, and the applied voltage was 2V. After electrifying for 5 hours, the removal rate of salt is 80%, the removal rate of phenol is 70%, and the removal rate of TOC is 45%. If no oxygen is introduced, the desalination rate is only 60%, and the phenol removal rate is only 50%. The introduction...

Embodiment 2

[0043] The method of the invention treats the waste water containing NaCl and phenol.

[0044] Prepare carbon airgel / polyvinylidene fluoride electrode as positive electrode (wherein carbon airgel mass fraction is 95%, polyvinylidene fluoride 5%), prepare carbon airgel / ferric oxide / polyvinylidene fluoride electrode as Negative electrode (the mass fraction of carbon airgel is 25%, the content of ferroferric oxide is 25%, the content of polyvinylidene fluoride is 50%, and ferric oxide is loaded on the surface of carbon aerogel by co-precipitation method), the mass of positive and negative electrodes 1g respectively. The solution in the storage tank was aerated with oxygen at 500ml / min, and Fe ions were not added. 100ml of wastewater containing 0.1g / L NaCl and 0.01mmol / L phenol was circulated through the electrode at a flow rate of 40ml / min, the wastewater temperature was 60°C, and the applied voltage was 4V. After electrifying for 10 minutes, the removal rate of salt is 50%, th...

Embodiment 3

[0046] The method of the invention treats the waste water containing NaCl and phenol.

[0047] Prepare the mesoporous carbon / polyvinylidene fluoride electrode as the positive and negative electrodes of the electrochemical wastewater treatment unit. The total mass is 20g. The solution in the storage tank is exposed to oxygen at 500ml / min, and 0.5mmol / L FeSO is added 4 . Circulate 100ml of wastewater containing 5g / L NaCl and 10mmol / L phenol through the electrode at a flow rate of 40ml / min, the temperature of the wastewater is 10°C, the applied voltage is 4V, and after energizing for 5 hours, the desalination rate is 55%, and the phenol removal rate is 100%. , TOC removal rate is 60%. If FeSO is not added 4 , The removal rate of phenol is 90%, and the removal rate of TOC is 45%. Explain adding Fe 2+ Generates strong oxidizing substances and promotes the degradation of phenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com