Method for preparing low-carbon olefins by using oxygen-containing compounds

A technology of low-carbon olefins and compounds, which is applied in the direction of producing hydrocarbons from oxygen-containing organic compounds, hydrocarbon cracking, chemical instruments and methods, etc., can solve the problem of low yield of low-carbon olefins, so as to improve yield and optimize energy The effect of distribution and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

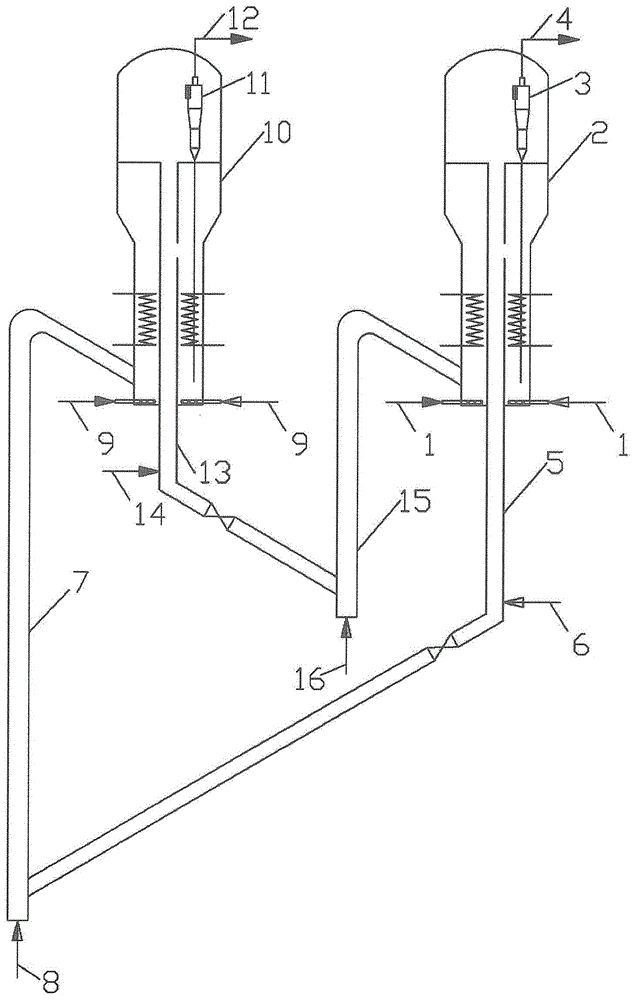

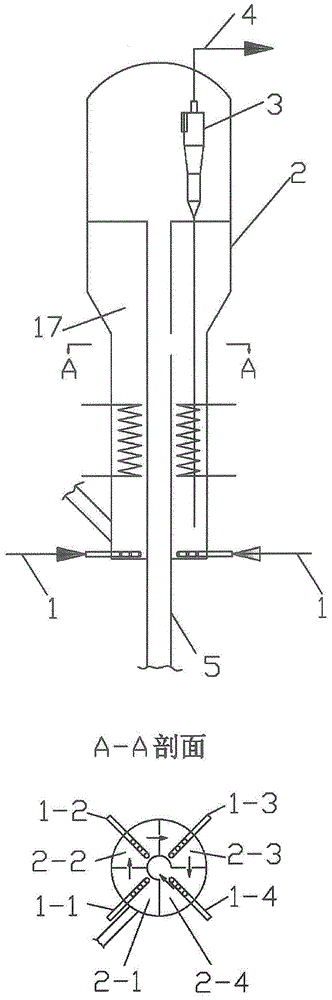

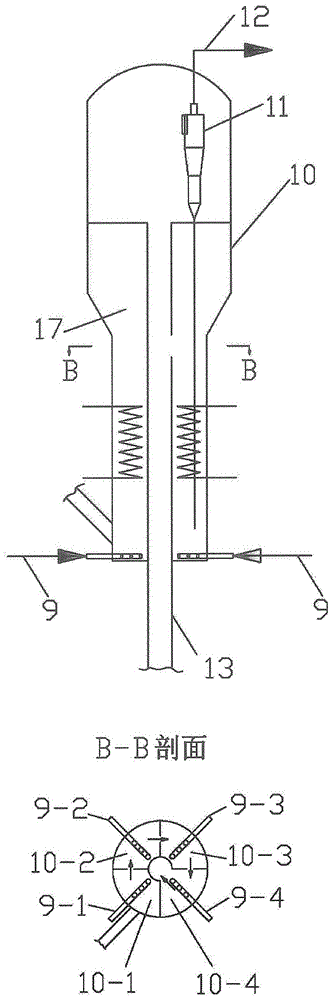

[0069] In the dense-phase fluidized bed reactor, there is one secondary pre-coking zone and three secondary reaction zones, and in the dense-phase fluidized bed regenerator, there are four secondary regeneration zones. Hydrocarbons above C4 enter the first secondary carbon pre-deposition zone in the dense-phase fluidized bed reactor, contact with the fully regenerated catalyst, and convert them into products including low-carbon olefins. At the same time, the amount of carbon deposition on the catalyst reaches At a certain value, a pre-carbon deposition catalyst is formed, and the pre-carbon deposition catalyst enters the reaction zone; raw materials containing oxygenated compounds enter the first to third secondary reaction zones in the dense-phase fluidized bed reactor in parallel, and the pre-carbon deposition Catalysts pass through the first to third secondary reaction zones sequentially in series, and the feedstock containing oxygenates is contacted with the pre-deposited ...

Embodiment 2

[0071]One secondary pre-carbon deposition area and two secondary reaction areas are set in the dense-phase fluidized bed reactor, and two secondary regeneration areas are set in the dense-phase fluidized bed regenerator. Catalysts above C4 enter the first secondary carbon deposit zone in the dense-phase fluidized bed reactor, contact with the fully regenerated catalyst, and convert them into products including low-carbon olefins. At the same time, the amount of carbon deposit on the catalyst reaches At a certain value, a pre-carbon deposition catalyst is formed, and the pre-carbon deposition catalyst enters the reaction zone; raw materials containing oxygenated compounds enter the first to second secondary reaction zones in the dense-phase fluidized bed reactor in parallel, and the pre-carbon deposition Catalysts pass through the first to second secondary reaction zones sequentially in series, and the feedstock containing oxygenates is contacted with the pre-deposited carbon ca...

Embodiment 3

[0073] A dense-phase fluidized bed reactor is provided with 1 secondary pre-carbon deposition zone and 5 secondary reaction zones, and a dense-phase fluidized bed regenerator is provided with 5 secondary regeneration zones. After mixing naphtha and hydrocarbons above C4, it enters the first secondary pre-coking zone in the dense-phase fluidized bed reactor, contacts with a fully regenerated catalyst, and converts it into products including low-carbon olefins. At the same time, the catalyst When the amount of carbon deposit reaches a certain value, a pre-carbon deposit catalyst is formed, and the pre-carbon deposit catalyst enters the reaction zone; raw materials containing oxygenated compounds enter the first to fifth secondary reaction zones in the dense-phase fluidized bed reactor in parallel At the same time, the pre-coke catalyst passes through the first to fifth secondary reaction zones sequentially in series, and the feedstock containing oxygenates contacts with the pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com