Method for preparing anti-rust emulsifier by using industrial by-product terpinene

A technology of by-product terpinene and emulsifier, which is applied in the petroleum industry, sulfonate preparation, additives, etc., can solve the problems of difficult separation and difficult to produce economic benefits, and achieve sufficient sources, simple and easy reaction operation, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

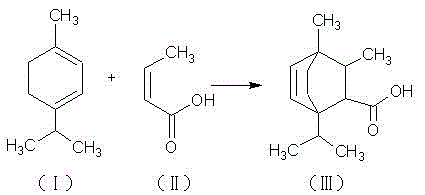

Image

Examples

Embodiment 1

[0019] In a four-necked flask equipped with a stirring device and a thermometer, add 200 grams of terpinene and 142 grams of α-butenoic acid, add 16 grams of catalyst p-toluenesulfonic acid, and heat up to 150 ° C ~ 160 ° C under reflux reaction 4~6 hours, generate addition product terpinene butyrate compound; Get the addition product terpinene butyrate compound of 222.3 grams of generation, add in the there-necked flask that stirrer and thermometer are housed, add 104 gram hydrogen peroxide, at 30 Under the action of 2.5 grams of glacial acetic acid and 2.5 grams of concentrated sulfuric acid, the epoxidation reaction was carried out at 60 to 75 ° C for 3 to 3.5 hours, and the epoxidized terpinene butyric acid compound was slowly added to 125 grams of concentrated sulfuric acid, and in an ice-water bath After carrying out sulfonation reaction for 2-4 hours, finally carry out alkali neutralization with saturated sodium carbonate aqueous solution to pH value of 7-8, separate org...

Embodiment 2

[0021] In a four-necked flask equipped with a stirring device and a thermometer, add 200 grams of terpinene and 118 grams of α-butenoic acid, add 16 grams of catalyst p-toluenesulfonic acid, heat up to 160 ° C ~ 170 ° C under reflux reaction 4~6 hours, generate addition product terpinene butyrate compound; Get the addition product terpinene butyrate compound of 222.3 grams of generation, add in the there-necked flask that stirrer and thermometer are housed, add 150 gram hydrogen peroxide, at 32 Under the action of 1 g of glacial acetic acid and 3 g of concentrated sulfuric acid, the epoxidation reaction was carried out at 70 to 80 ° C for 3.0 to 3.5 hours, and the epoxidized terpinene butyric acid compound was slowly added to 140 g of concentrated sulfuric acid, and the mixture was cooled in an ice-water bath. After carrying out sulfonation reaction for 2-4 hours, finally carry out alkali neutralization with saturated sodium carbonate aqueous solution to pH value of 7-8, separa...

Embodiment 3

[0023] In a four-necked flask equipped with a stirring device and a thermometer, add 200 grams of terpinene and 130 grams of α-butenoic acid,

[0024] Add 25 grams of catalyst p-toluenesulfonic acid, heat up to 170°C to 180°C for reflux reaction for 4 to 6 hours, and generate the addition product terpinene butyric acid compound; take 222.3 grams of the generated addition product terpinene butyrate acid compound, put it into a three-necked flask equipped with a stirring device and a thermometer, add 134 grams of hydrogen peroxide, and under the action of 33 grams of glacial acetic acid and 3.5 grams of concentrated sulfuric acid, epoxidize it at 60-70 ° C for 2.5-3 hours to form The epoxidized terpinene butyric acid compound, slowly add 170 grams of concentrated sulfuric acid, carry out sulfonation reaction in an ice-water bath for 2 to 4 hours, and finally carry out alkali neutralization with saturated sodium carbonate aqueous solution to a pH value of 7 to 8, Separation of or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com