A kind of polyalkylsiloxane-polyolefin block copolymer and its preparation method and application

A technology of polyalkylsiloxane and polyolefin block, which is applied in the field of polyalkylsiloxane-polyolefin block copolymer and its preparation, can solve the problem of wide molecular weight distribution, high temperature and inconsistent product structure of the copolymer. Ideal and other problems, to achieve the effect of good modification effect, easy structure and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

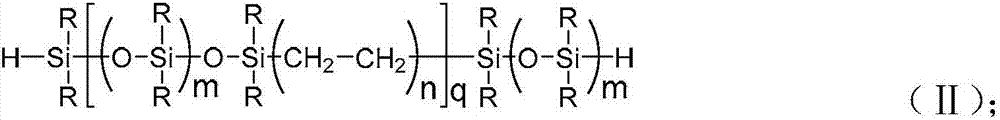

[0036] (1) In a flask equipped with a stirrer, condensing reflux, and inlet pipe, add 24.42g (0.182mol) tetramethyldisiloxane (that is, R is methyl in formula 3, and m is 1), 18.2 g (0.165 mol) octadiene (CAS: 3710-30-3), 0.128 g (10 ppm) platinum catalyst and 100 ml toluene. After the device was filled with nitrogen atmosphere, it was heated to 40° C. and stirred for 5 h. After the stirring was completed, unreacted raw materials and toluene were distilled off under reduced pressure at a temperature of 40° C. to obtain 38 g of light yellow transparent polyalkylsiloxane.

[0037] (2) 8.5g (3.36mmol) of the polyalkylsiloxane obtained in step (1), 25.50g (6.72mmol) of polyethylene and 50ml of toluene were added to a flask equipped with a stirrer, condensing reflux device, and inlet pipe , when the device was filled with nitrogen atmosphere, heated to 110°C and stirred for 10h. After the device was cooled, the toluene was removed by suction filtration under reduced pressure, and...

Embodiment 2

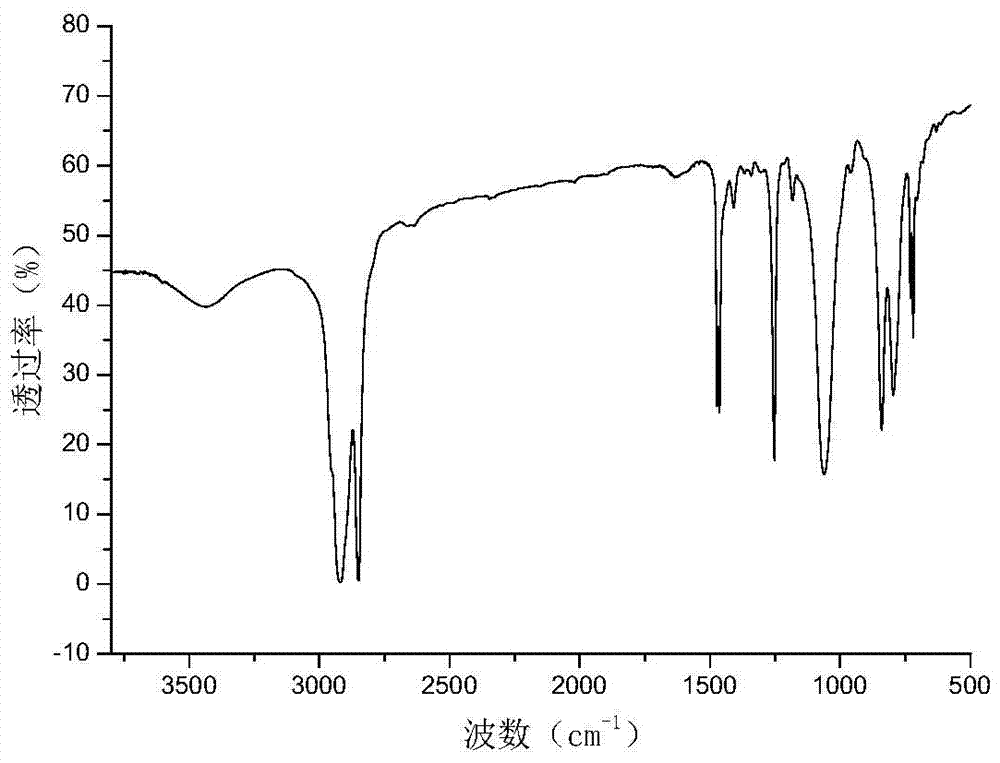

[0039] Repeat the steps of Example 1, except that the siloxane polymer of formula 3 with m=10 (instead of tetramethyldisiloxane) is added in step (1), and the reaction temperature of the first step is 80°C. final polymer through 1 H-NMR and infrared spectroscopy confirmed that it is a block copolymer with polyalkyl hybrid siloxane segment and polyethylene segment. 1 H-NMR analysis determined that the polymer had a siloxane content of 37.3 wt%. The polyalkylhybridsiloxane-polyolefin block copolymer had an Mn of 13800 g / mol as determined by GPC analysis.

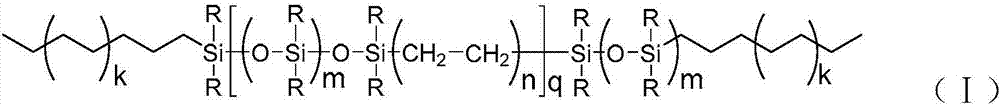

[0040] [Formula 3]

[0041]

Embodiment 3

[0043] Repeat the steps of Example 1, except that the siloxane polymer of formula 3 with m=20 is added in step (1), and the reaction temperature of the first step is 80°C. final polymer through 1 H-NMR and infrared spectroscopy confirmed that it is a block copolymer with polyalkyl hybrid siloxane segment and polyethylene segment. 1 H-NMR analysis determined that the polymer had a siloxane content of 46.3 wt%. The polyalkylhybridsiloxane-polyolefin block copolymer had an Mn of 15200 g / mol as determined by GPC analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com