A kind of intercalation material for enhancing the interlayer performance of continuous fiber resin-based composite board and its preparation method

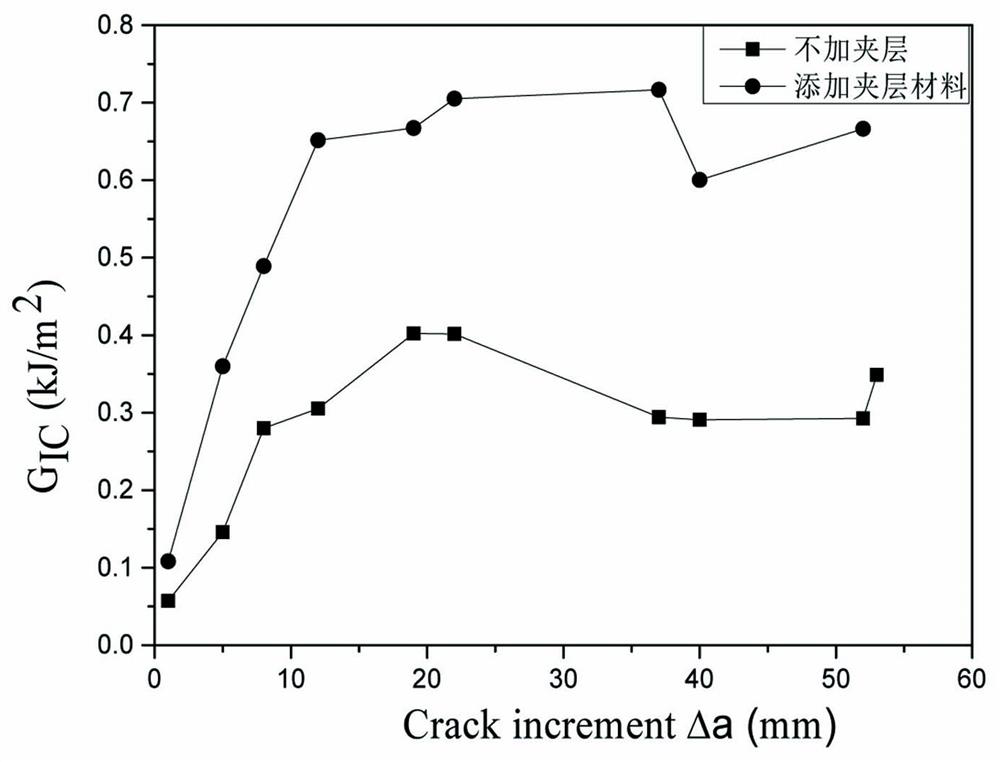

A technology of intercalation materials and composite materials, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of adverse effects on strength and modulus, limiting toughening effects, etc., and achieves easy structure control and great operability , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing an intercalation material for enhancing the interlayer performance of a continuous fiber resin-based composite board, comprising the steps of:

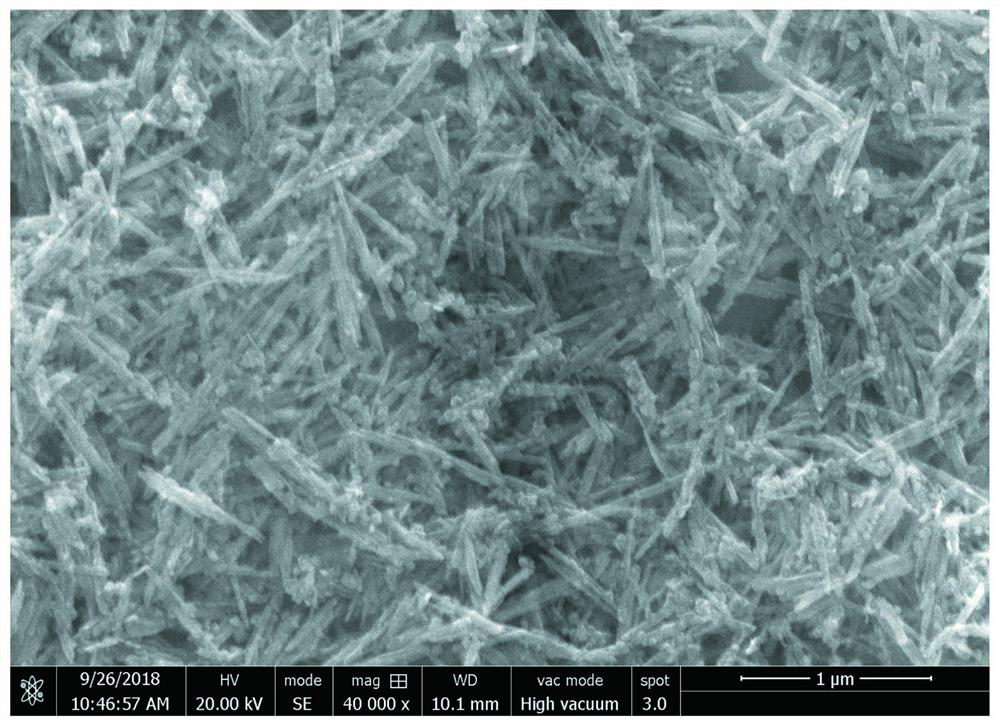

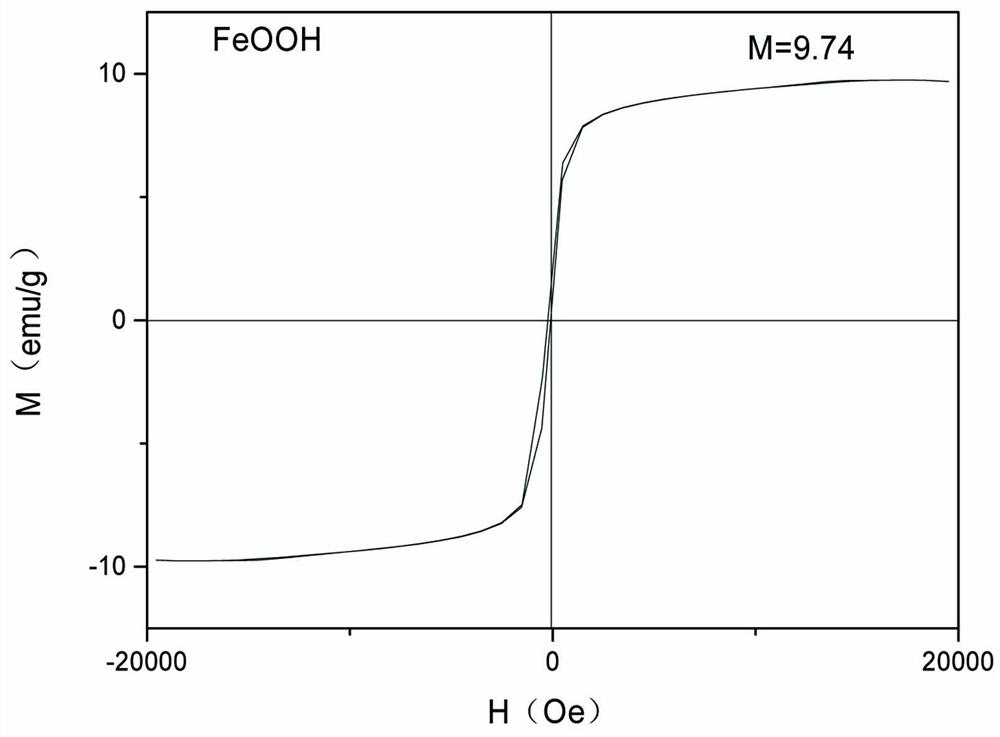

[0034] (1) Alcohol was selected as solvent, needle-shaped magnetic FeOOH nanoparticles were used as dispersed particles, KH-550 was used as coupling agent, polyvinylpyrrolidone was used as dispersant, needle-shaped magnetic FeOOH nanoparticles, KH-550, polyvinylpyrrolidone Dissolved in alcohol to form a mixed solution; the mass fractions of needle-shaped magnetic FeOOH nanoparticles, KH-550, and polyvinylpyrrolidone in alcohol were: 20%, 5%, and 10%; the morphology of needle-shaped magnetic FeOOH nanoparticles Figure such as figure 1 As shown, the hysteresis loop diagram of the acicular magnetic FeOOH nanoparticles is shown in figure 2As shown, it can be seen from the figure that the coercive force of the nanoparticles is almost zero, and there is superparamagnetism, which provides a guarantee for the s...

Embodiment 2

[0039] A method for preparing an intercalation material for enhancing the interlayer performance of a continuous fiber resin-based composite board, comprising the steps of:

[0040] (1) Using acetone as solvent, needle-like magnetic Fe 2 o 3 Nanoparticles As dispersed nanoparticles, KH-560 was used as a coupling agent, polyvinylpyrrolidone was used as a dispersant, and acicular magnetic Fe 2 o 3 Nanoparticles, KH-560, polyvinylpyrrolidone dissolved in acetone to form a mixed solution; needle-like magnetic Fe 2 o 3 The mass fractions of nanoparticles, KH-560, and polyvinylpyrrolidone in acetone are: 1%, 1%, and 0.5% respectively;

[0041] (2) Use non-woven fabric made of polyurethane, place it in a magnetic field with a magnetic induction intensity of 1T, and fix it;

[0042] (3) Spray the mixed solution obtained in step (1) evenly on the surface of the non-woven fabric described in step (2), place it in a magnetic field for 1 hour, and orient;

[0043] (4) Place the orie...

Embodiment 3

[0045] A method for preparing an intercalation material for enhancing the interlayer performance of a continuous fiber resin-based composite board, comprising the steps of:

[0046] (1) Choose water as solvent, needle-like magnetic Fe 3 o 4 Nanoparticles are dispersed nanoparticles, KH-570 is used as coupling agent, water-soluble acrylic polymer dispersant is used as dispersant, and acicular magnetic Fe 3 o 4 Nanoparticles, KH-570, polyvinylpyrrolidone dissolved in water to form a mixed solution; needle-like magnetic Fe 3 o 4 The mass fractions of nanoparticles, KH-570, and water-soluble acrylic polymer dispersant in water are: 5%, 5%, and 5%, respectively.

[0047] (2) Use non-woven fabric made of polyurethane, and arrange a magnetic field with a magnetic induction intensity of 0.5T;

[0048] (3) Immerse the polyurethane non-woven fabric in the mixed solution of step (1), and fix it in the magnetic field of step (2) for 2 hours, such as Figure 6 The device shown dip-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com