Method and device for quenching coke and recovering energy

A coke quenching and coke technology, applied in the field of coke quenching and energy recovery and equipment, can solve the problems of high equipment investment and operation costs, heavy cost burden, and restrictions on the widespread popularization of dry coke quenching technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

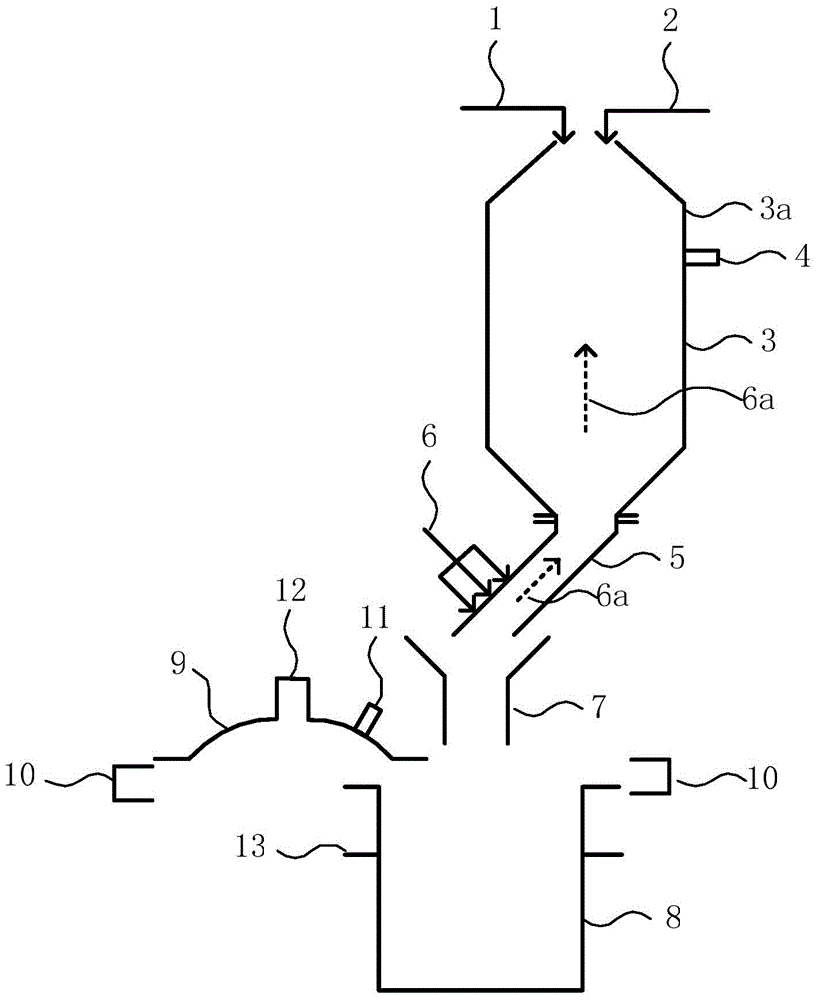

[0040] This embodiment is the coke quenching of red coke that is cooled by water-gas reaction and combined with a pressurized water vaporization cooling tank that discharges upside down. The system is as follows figure 1shown. 950-1050°C red coke 1 and coke powder 2 (added by 1% of the weight of red coke) are simultaneously added to the red coke pre-storage section 3a in the water-gas reaction cooling tank 3 from the top, move from top to bottom in the tank, and Water gas reacts with water vapor 6a to generate water gas, and then it is discharged from water gas outlet 4 and sent to the coke oven for combustion as gas. The coke that has been cooled to about 700°C by the water gas reaction enters the spraying water vaporization steam production cooling tank 5 and slides downward, and transfers heat with the sprayed water vaporization production steam cooling water inlet 6, and the water vaporization produces water vapor 6a that moves upwards and enters the water gas reaction coo...

Embodiment 2

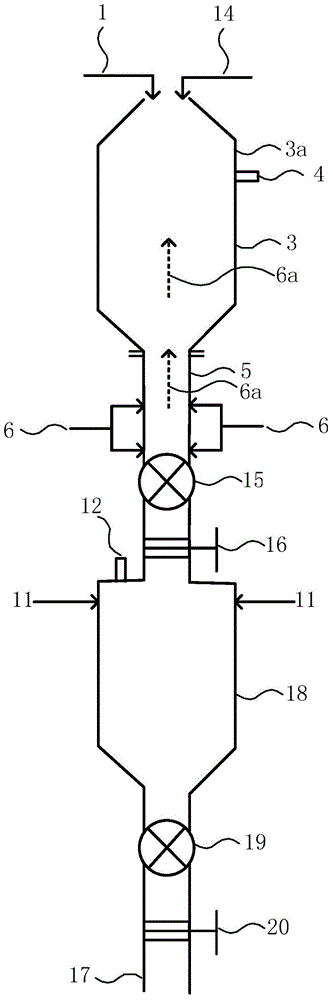

[0042] This example is a coke quenching scheme in which red coke is cooled by water gas reaction and combined with a fixed pressurized water vaporization cooling tank. The system is as follows figure 2 shown. The mixture 14 of red coke 1, anthracite and coke powder at 950-1050°C (10% by weight of red coke, wherein the coke powder and anthracite account for half each) is simultaneously added to the pre-stored section 3a in the water gas reaction cooling tank 3 from the top, It moves from top to bottom in the tank, and reacts with water vapor 6a to generate water gas, then discharges from water gas outlet 4 and sends it to the boiler for combustion as gas. The coke that has been cooled to about 720°C by the water gas reaction enters the sprinkling vaporization steam production cooling tank 5 and moves downward, and transfers heat with the sprayed water vaporization production steam cooling water inlet 6, and the water vaporization produces water vapor 6a and moves upward into t...

Embodiment 3

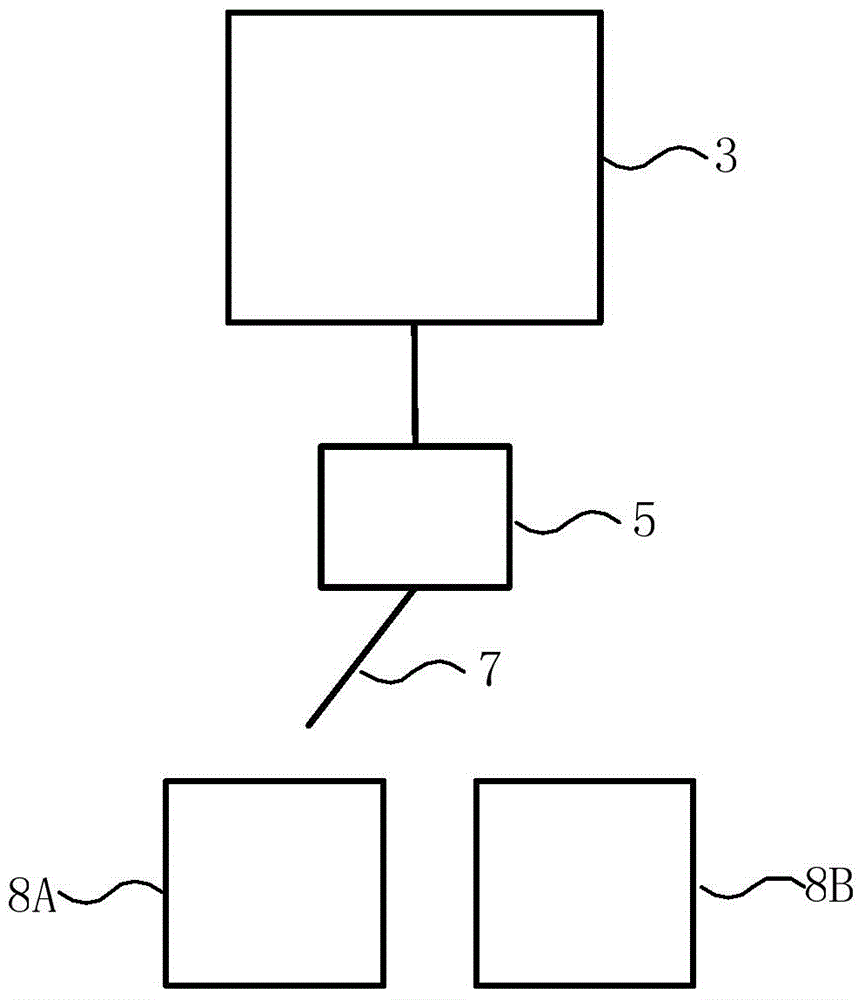

[0044] This embodiment is basically the same as Embodiment 1, the difference is that the pressurized water vaporization and cooling process is completed alternately by two parallel up and down pouring type pressurized water vaporization and cooling tanks, the system is as follows image 3 shown. Red coke and coke powder (added according to 6% of the weight of red coke) are imported into the water gas reaction cooling tank to cool down, and then the water is vaporized to produce steam to cool down, and then introduced into the pressurized water vaporization cooling tank 8A through the mobile coke chute, after reaching the predetermined coke quantity The mobile coke chute is transferred to the pressurized water vaporization cooling tank 8B to import coke; the pressurized water vaporization cooling tank 8A filled with coke is sealed (the process is as in embodiment 1) spraying water vaporization cooling, when the cooling tank 8B is full of coke , and after the coke cooling proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com