Fermentation method for increasing yield of polysaccharide as active ingredient of biological flocculants

A technology of biological flocculants and active ingredients, which is applied in the field of fermentation to improve the active ingredients of biological flocculants, can solve problems such as instability, low output, and complex industrial fermentation processes, and achieve obvious effects, increase content, and increase activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

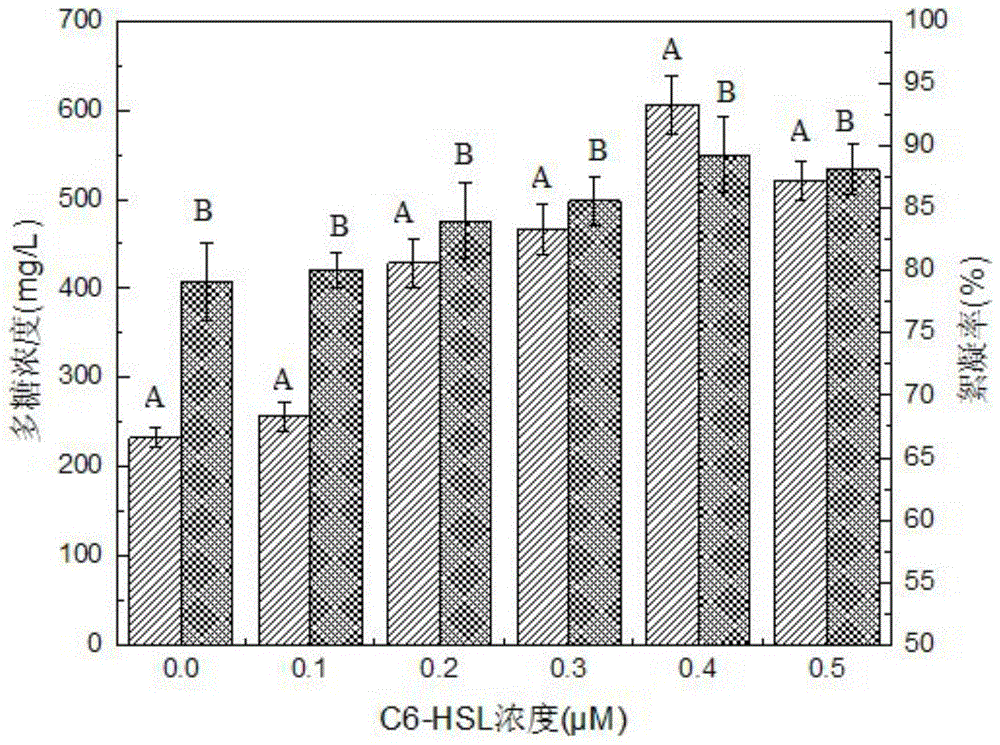

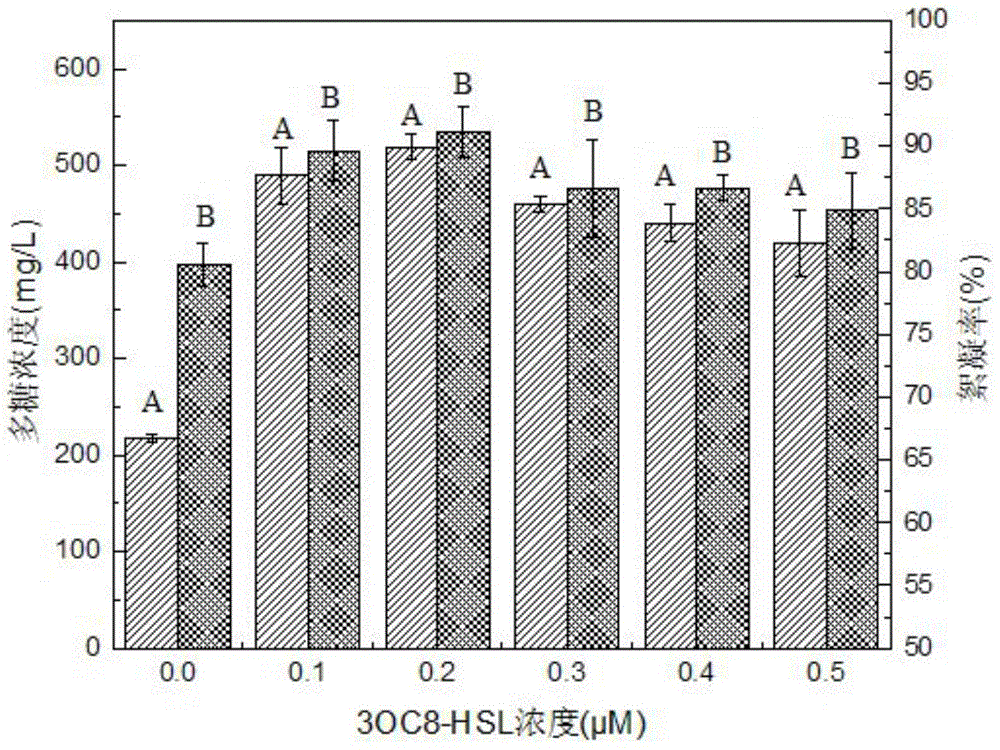

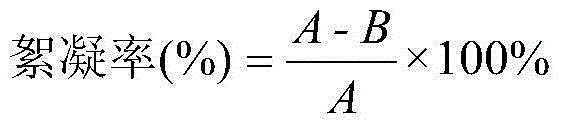

[0012] Embodiment 1: A fermentation method for increasing the yield of polysaccharides, the active ingredient of a bioflocculant, according to this embodiment, is operated in accordance with the following steps: first, inoculate the bioflocculant producing bacteria into the flocculation fermentation liquid medium, and ferment to prepare the seeds liquid; then inoculate the seed liquid in the flocculation fermentation liquid medium added with exogenous AHLs, and carry out secondary fermentation to obtain the bioflocculant, and complete the fermentation of improving the polysaccharide production of the active ingredient of the bioflocculant; wherein , the exogenous AHLs are N-3-oxo-octanoyl homoserine lactone and N-hexanoyl homoserine lactone or one or both of them are mixed in any ratio; among them, the flocculation fermentation liquid added with exogenous AHLs The culture medium is to add exogenous AHLs into the flocculation fermentation liquid medium until the final concentrat...

specific Embodiment approach 2

[0013] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the bioflocculant-producing bacteria are Gram-negative bacteria. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the gram-negative bacteria is Agrobacterium tumefaciems (Agrobacterium tumefaciems) F2, which is preserved in China Microorganism Culture Collection Center, and the preservation address is Beichen West, Chaoyang District, Beijing No. 3, Courtyard No. 1, the preservation date is December 03, 2014, and its CGMCC number is 10131. Others are the same as in the first embodiment.

[0015] The bioflocculant-producing bacteria Agrobacterium tumefaciems F2 of this embodiment is a Gram-negative bacterium, and the bioflocculant produced by it is a metabolite of the bacterium, and its flocculation active ingredients mainly exist in the fermentation broth. The flocculation rate reaches more than 80%, and has good thermal stability; through experiments, it is confirmed that the polysaccharide in the biological flocculant of Agrobacterium tumefaciems (Agrobacterium tumefaciems) F2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com