A method for preparing zinc sulfide/amperophilic imide hybrid semiconductor materials with different crystal phases

A technology of perylene imide and perylene diimide is applied in the field of zinc sulfide/biphilic perylene imide hybrid materials, which can solve the problems of poor flexibility and tailorability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

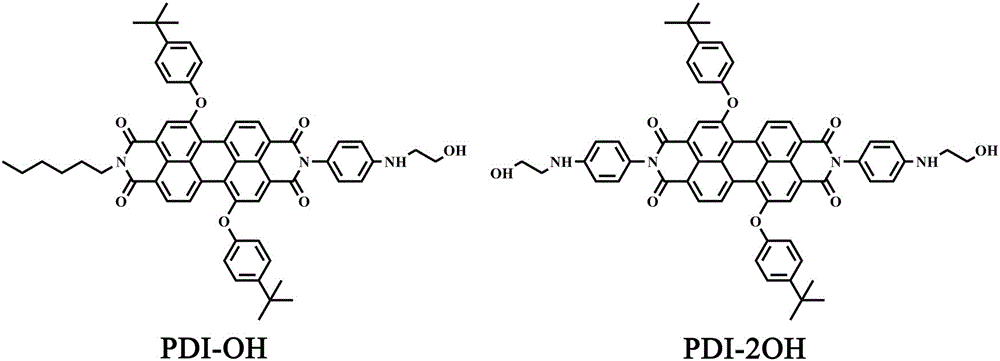

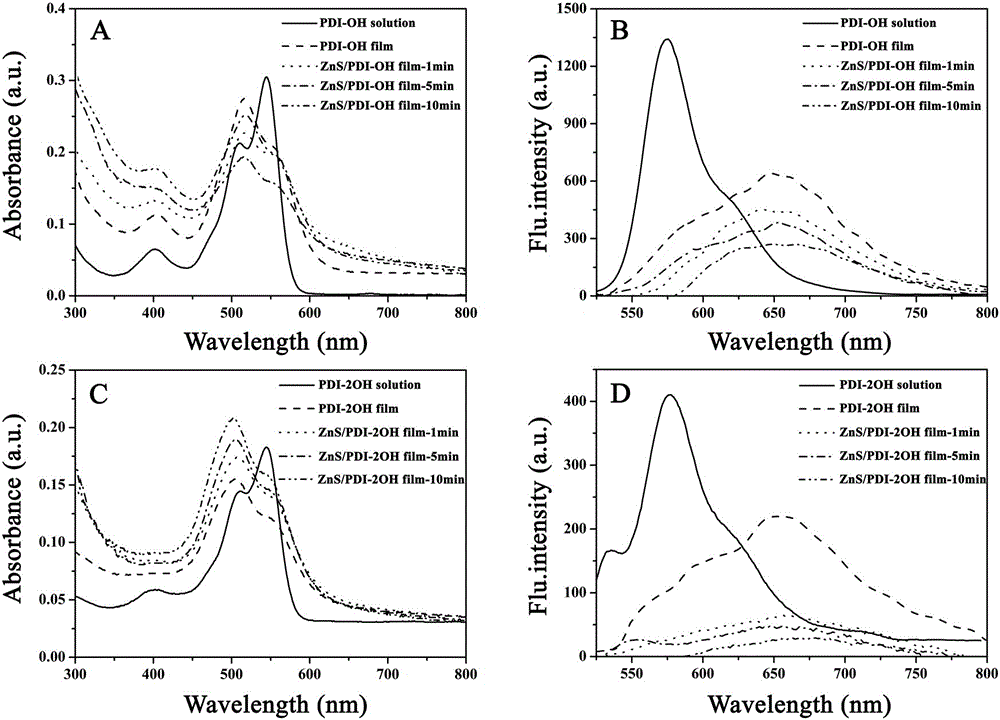

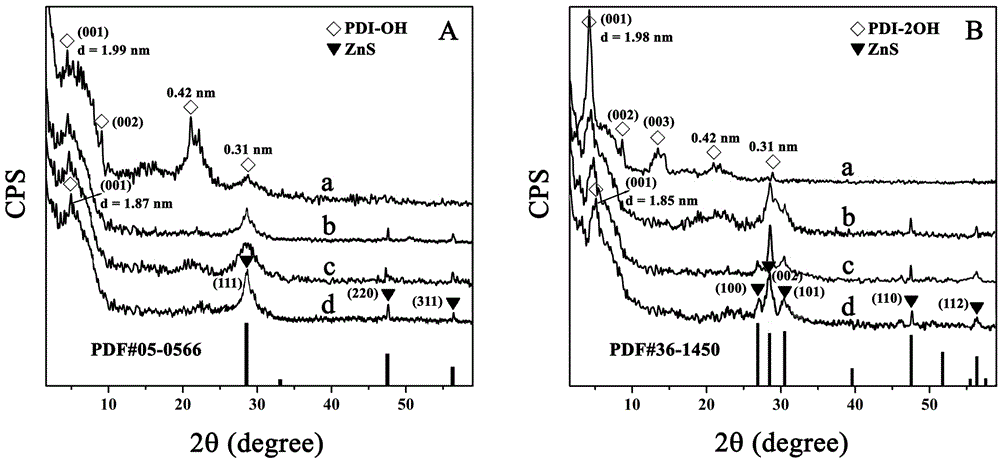

[0032] 1 Preparation of PDI-OH self-assembled film and ZnS / PDI-OH hybrid film

[0033] (1) PDI-OH self-assembled membrane: 5.0 ml containing PDI-OH ( figure 1 ) in dichloromethane (0.20 mg mL -1 ), added to the Petri dish (diameter: 90 mm, height: 1.8 cm), and then 50 mL of water was slowly added to the surface of the dichloromethane solution. (Note: The amount of water added cannot make the air / CH 2 Cl 2 The interface is completely covered, leaving a small hole for CH 2 Cl 2 The solvent can evaporate along the way). During the solvent evaporation process, the PDI-OH molecule will gradually be in the CH 2 Cl 2 - Self-assembly at the interface of water to form excellent nanostructures. Wait for CH 2 Cl 2 The volatilization is complete, and the densely packed film will remain on the water surface ( figure 2 ). Then, with 300 mesh copper mesh, quartz sheet and Si / SiO 2 The substrate is taken out by horizontal pulling method. During the transfer process and after the...

example 2

[0045] 1 Preparation of PDI-OH self-assembled film and ZnS / PDI-OH hybrid film

[0046] (1) PDI-OH self-assembled film: The method and conclusion are consistent with the method and conclusion of "1 (1)" in "Example 1".

[0047] (2) ZnS / PDI-OH self-assembled membrane: replace the aqueous solution in the petri dish with ZnSO 4 Aqueous solution (0.081 mg mL -1 ), repeat the above steps to prepare monolayer Zn 2+ / PDI-OH self-assembled film, then, with 300-mesh copper mesh, quartz sheet and Si / SiO 2 The film is taken out of the substrate by horizontal pulling method, and the monolayer film is immersed in the pre-configured H 2 S saturated solution (~0.1mol L -1 ) for 5 min, then the monolayer membrane was removed and carefully rinsed 3 times with distilled water. During the transfer process and after the transfer process is completed, there will be water droplets remaining on the copper grid or substrate, which can be dried naturally. It can be repeated 15 times to prepare 15 l...

example 3

[0058] 1 Preparation of PDI-OH self-assembled film and ZnS / PDI-OH hybrid film

[0059] (1) PDI-OH self-assembled film: The method and conclusion are consistent with the method and conclusion of "1 (1)" in "Example 1".

[0060] (2) ZnS / PDI-OH self-assembled membrane: replace the aqueous solution in the petri dish with ZnSO 4 Aqueous solution (0.081 mg mL -1 ), repeat the above steps to prepare monolayer Zn 2+ / PDI-OH self-assembled film, then, with 300-mesh copper mesh, quartz sheet and Si / SiO 2 The film is taken out of the substrate by horizontal pulling method, and the monolayer film is immersed in the pre-configured H 2 S saturated solution (~0.1mol L -1 ) for 10 min, then the monolayer membrane was removed and carefully rinsed 3 times with distilled water. During the transfer process and after the transfer process is completed, there will be water droplets remaining on the copper grid or substrate, which can be dried naturally. It can be repeated 15 times to prepare 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com