Novel PTC thermosensitive element

A thermal element, a new type of technology, applied in the direction of resistors with positive temperature coefficients, etc., can solve the problems of small electrode resistance, low protection switch temperature, etc., and achieve the effect of small electrode resistance, low protection switch temperature, and large operating current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

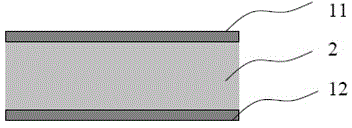

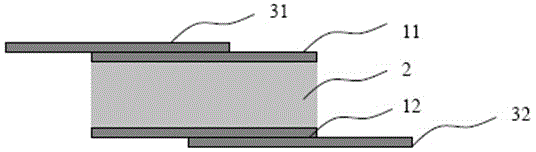

[0033] like figure 2 Shown in the structural representation of this embodiment:

[0034] Press the conductive composite base layer 2 respectively figure 1 As shown, it is placed between the upper metal foil 11 and the lower metal foil 12, and they are closely combined by thermocompression. The temperature of hot pressing is 180 degrees centigrade, and the pressure is 12 MPa, and the time is 10 minutes, and finally cold pressing on the cold press for 10 minutes to obtain figure 1 A conductive composite chip with positive temperature coefficient of resistance effect shown. Then, through the punching process, the conductive composite material chip is punched into a small chip of 3mm*4mm, and then the small chip is welded with the upper and lower conductive parts 31 and 32 with a copper content of more than 99.9% through a reflow soldering process to form a PTC heat sink. Sensitive components, such as figure 2 .

Embodiment 2

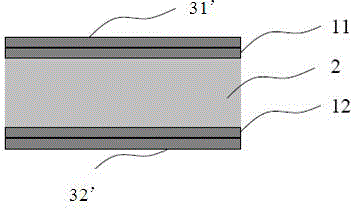

[0036] This embodiment has the same structure and manufacturing process as Embodiment 1, except that the areas of the upper and lower conductive parts 31', 32' are the same size as the area of the chiplets.

Embodiment 3

[0038] This embodiment and embodiment 1 have the same structure and manufacturing process, except that the area of the upper conductive part 31'' is the same size as that of the small chip, and the lower conductive part 32'' is longer than the small chip, which is convenient for circuit connection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com