Strain sterilizer

A technology for sterilizing stoves and strains, which is applied in the field of combustion, and can solve problems such as unstable temperature, ineffective use of waste heat of flue gas, and incomplete sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

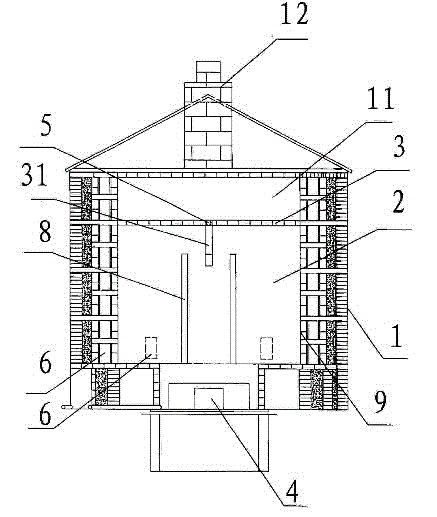

[0012] See figure 1 The heat insulation layer 3 arranged horizontally above the storage room 2 divides the stove body 1 into two chambers, and the lower chamber of the stove body 1 uses two vertical temperature-increasing walls 8 to separate the storage room 2 into an inverted "concave" shape. , the smoke exhaust channel 11 of the upper chamber communicates with the side temperature increasing wall 9 and the chimney 12, and a double-layer heater 4 is arranged under the temperature increasing wall 8, and the overlapping water pipes form a "herringbone" shape and are distributed at the bottom of the heater 4. A partition wall 31 is set below the heat insulation layer 3 and hangs between the two temperature increasing walls 8 . The fuel burns in the heater 4 under normal temperature and pressure, and the overflowing fire smoke enters the temperature-increasing wall 8, and then is divided into two parts by the partition wall 31 and enters the left and right spaces of the lower cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com