Method for preparing graphene through hypergravity technology

A hypergravity method and graphene technology, which is applied in the field of hypergravity method to prepare high-performance graphene with graphite as raw material, and achieves the effects of high production safety, environmental friendliness and good controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of method that supergravity method prepares graphene, comprises the following steps:

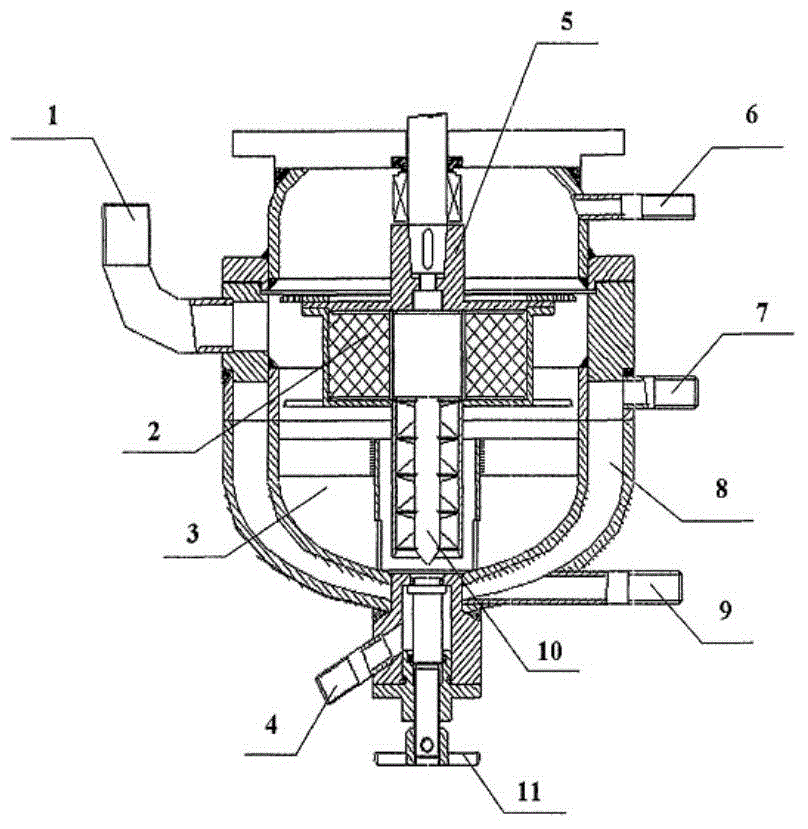

[0039] use figure 1 device.

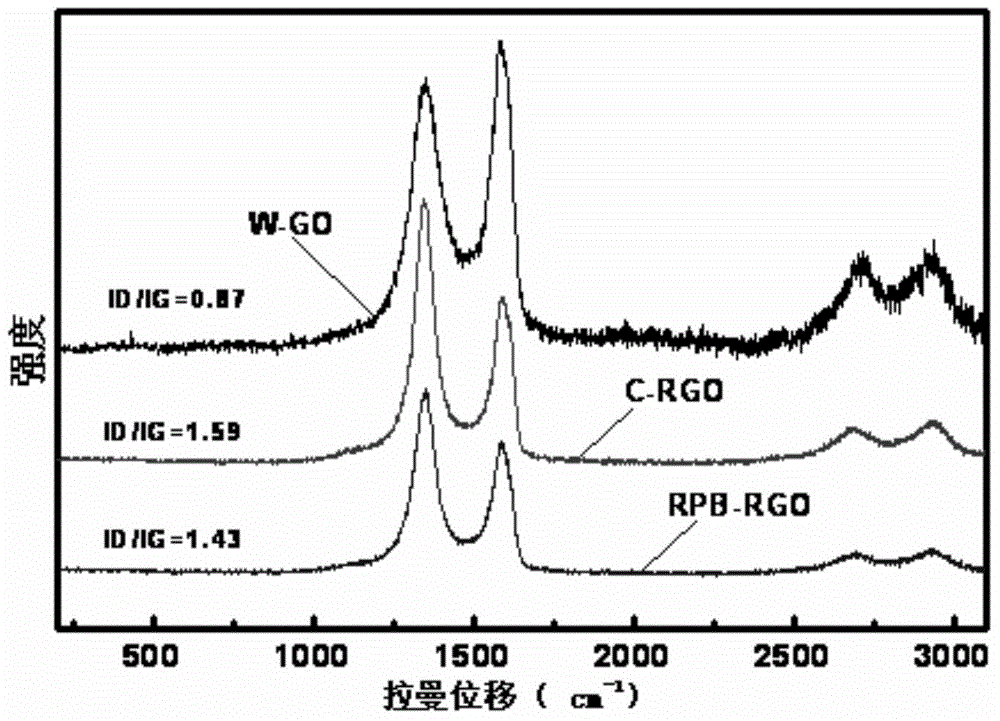

[0040] 1) Weigh 3g of natural graphite, use the Hummers method or improved Hummers, control the oxidation time and the amount of oxidant, and filter and wash to prepare weakly oxidized graphite (W-GO);

[0041] 2) Dilute the weakly oxidized graphite with water to 1000ml, add 5wt% polyvinylpyrrolidone PVP, stir it magnetically for 2 hours, then add it to a high-gravity rotating bed, add circulating water at 25°C, and peel it off for 10 hours;

[0042] 3) The exfoliated W-GO was reduced with vitamin C in a high-gravity rotating bed, the reduction temperature was 80°C, the reduction time was 1h, washed and filtered to obtain graphene.

Embodiment 2

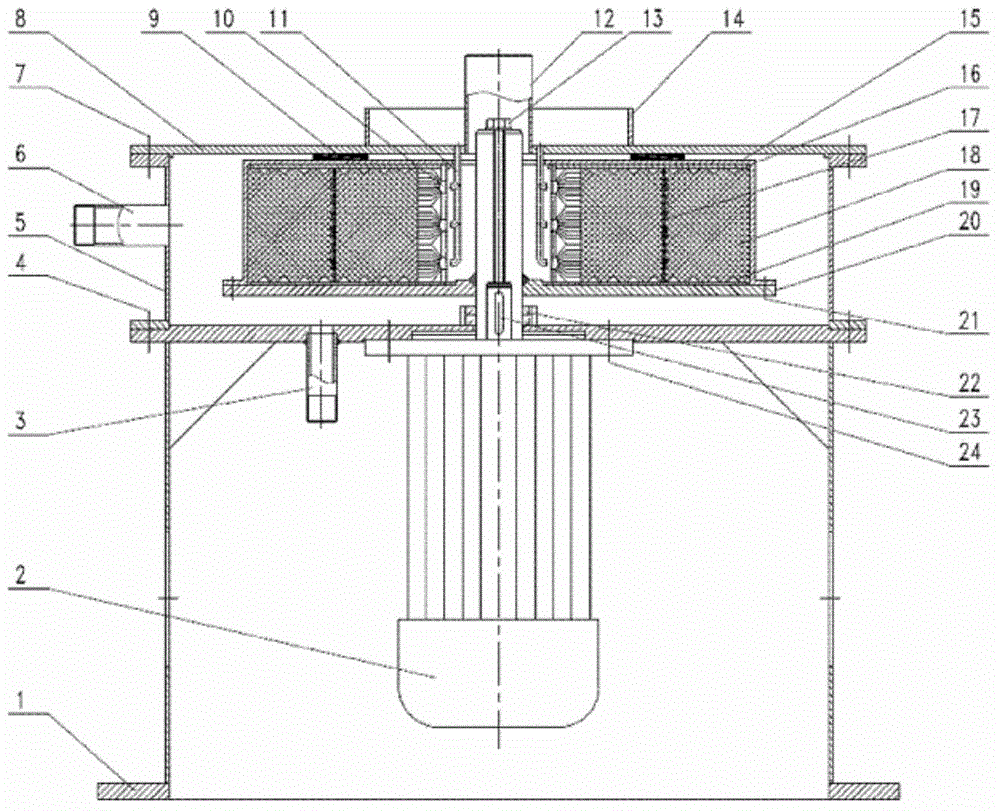

[0052] Same as Example 1, except that the internal circulating rotating bed device is replaced by an external circulating rotating bed device.

Embodiment 3

[0054] Same as Example 1, except that the graphite is microcrystalline graphite, the exfoliation time is 30 min, the reducing agent is glucose, the reduction temperature is 60 degrees Celsius, and the reduction time is 10 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com