Neodymium-doped low germanium-aluminum-gallium salt laser glass and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-16

[0034] The preparation method of embodiment 1-16 is as follows:

[0035] (1) Take high-purity raw materials according to the molar ratio of Examples 1-16 in Table 1, and use an agate ball mill jar for ball milling for 6 hours;

[0036] (2) Transfer the mixture prepared in the step (1) to a platinum crucible, and place the crucible under an air atmosphere at 1350-1500° C. for melting for 1 hour.

[0037] (3) Pour the melted glass liquid in step (2) onto a preheated iron plate, and after it is cooled and shaped, it is annealed in an annealing furnace at 700°C for 6 hours, and then cooled to room temperature with the furnace to obtain target glass.

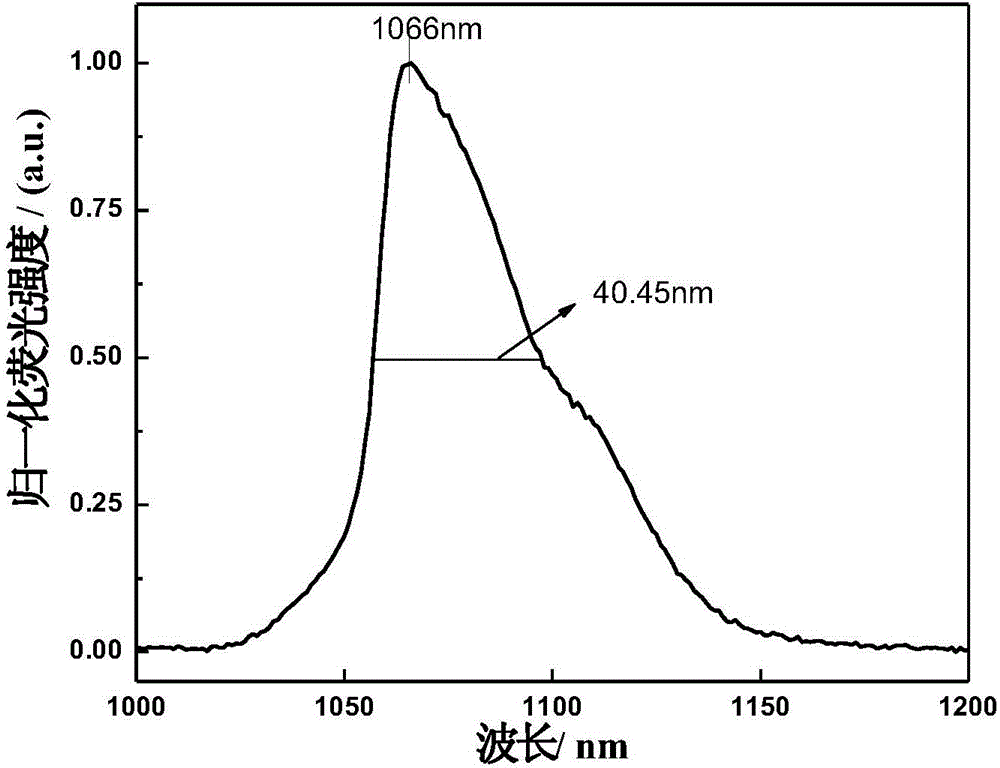

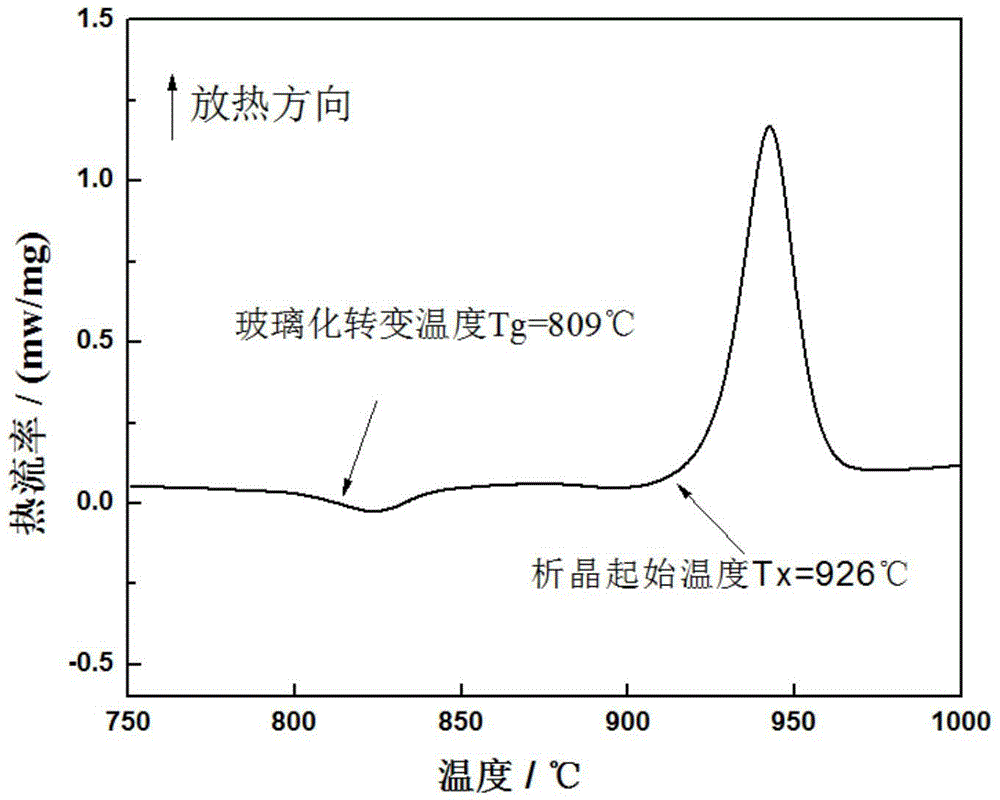

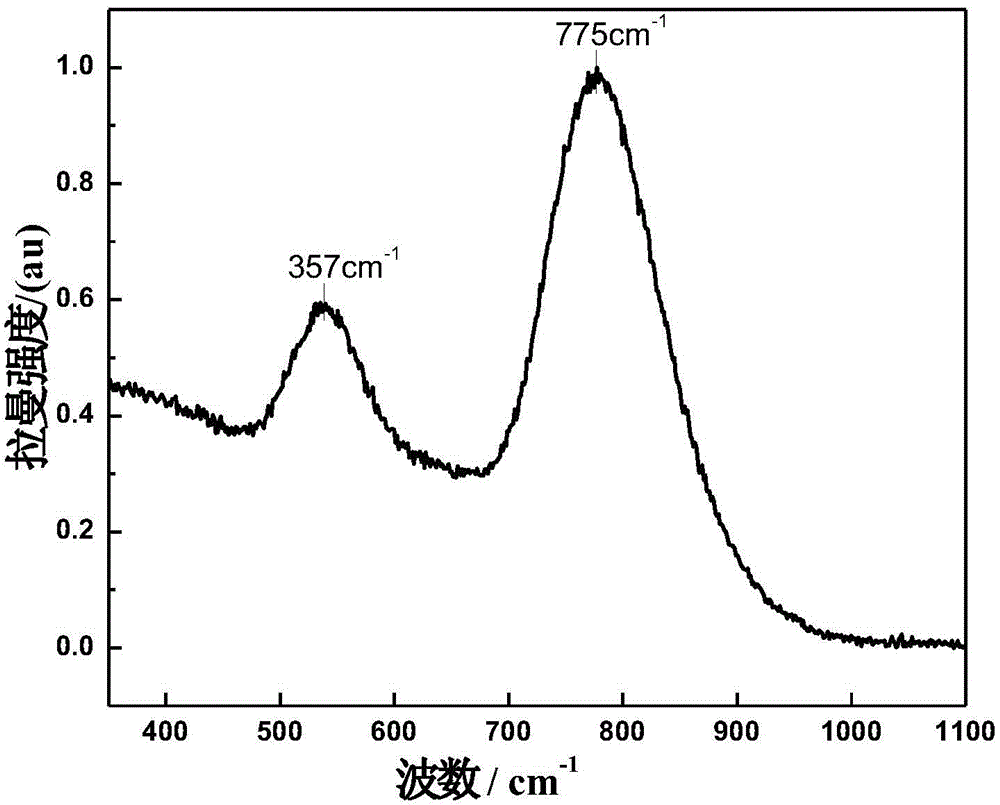

[0038] figure 1 For Example 7, a FLS920 time-resolved spectrometer was used to measure the fluorescence spectrum of the glass, the excitation source was a xenon lamp, the wavelength of the excitation light was 811 nm, and the near-infrared detector of the type Hamamatsu R5509 cooled by liquid nitrogen was used. figure 2 It is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com