Preparation method of deuterated ethylene

A technology of deuterated ethylene and deuterated acetylene, applied in the field of isotope gas preparation, can solve the problems of low utilization rate of raw materials, undisclosed reaction pressure, high price, etc., so as to improve the operation safety, improve the utilization rate of raw materials, and reduce the preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

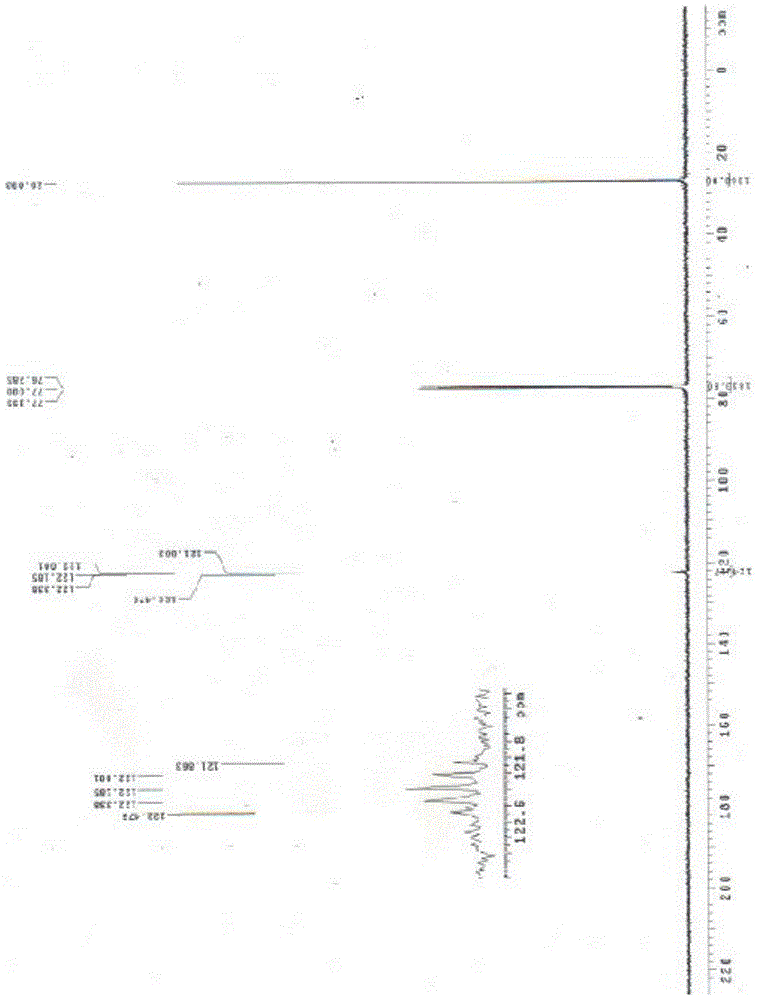

[0038] Carbide (CaC 2 ) and heavy water (D 2O) reacts as starting material, generates deuterated acetylene (C 2 D. 2 ); Deuterated acetaldehyde reacts with heavy water under acidic conditions to make high-content deuterated acetaldehyde (C 2 D. 4 O); with deuterated acetaldehyde and deuterium gas (D 2 ) is that raw material reacts with deuterium to make deuterated ethanol (C 2 D. 5 OD); The obtained deuterated ethanol is dehydrated by catalyst to obtain high-purity deuterated ethylene (C 2 D. 4 ). Based on heavy water, the total yield is greater than 41.51%.

[0039] The reaction principle is as follows:

[0040] Deuterated acetylene synthesis

[0041]

[0042] Synthesis of deuterated acetaldehyde

[0043] C 2 D. 2 +D 2 O→C 2 D. 4 o

[0044] Synthesis of deuterated ethanol

[0045]

[0046] Synthesis of deuterated ethylene

[0047]

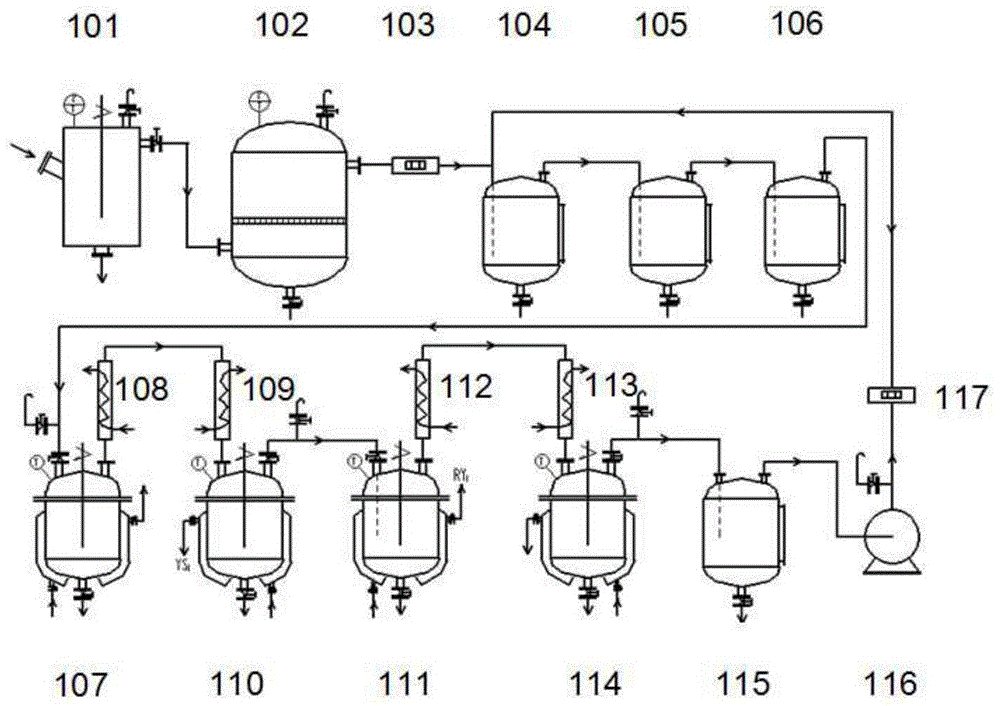

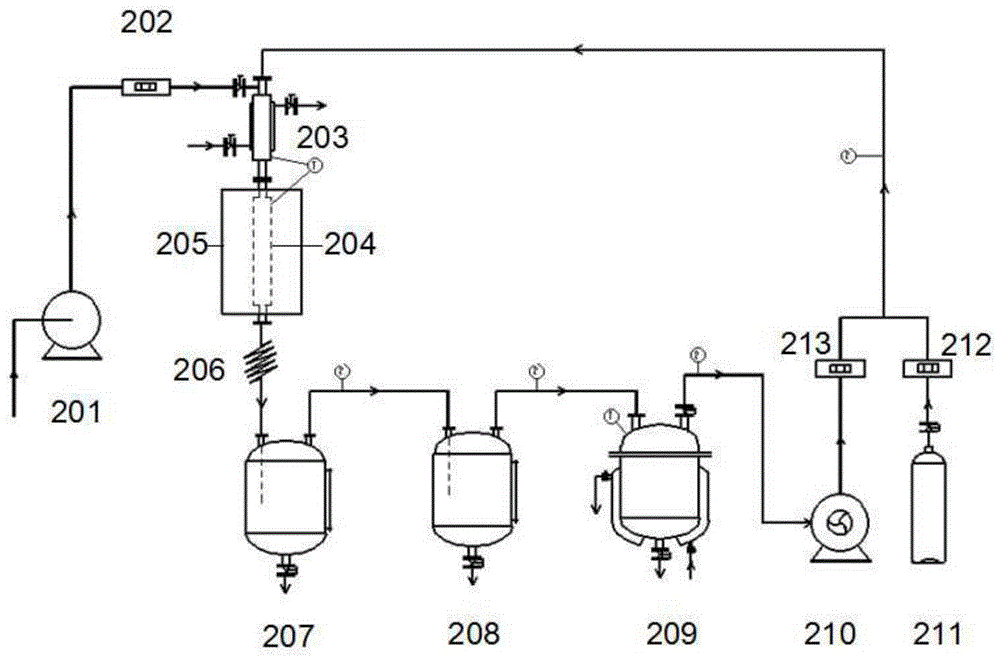

[0048] Attached below Figure 1-3 The preparation process of deuterated acetaldehyde, deuterated ethanol and deuter...

Embodiment 2

[0050] In a specific embodiment, the step of synthesizing deuterated acetylene is as follows: put calcium carbide qualified for processing into the deuterated acetylene generator 101 in excess. Under the condition of 0~100℃, add D dropwise at a uniform speed 2 O, maintain the pressure in the acetylene reactor 101 at 0-0.5Mpa. The acetylene release rate is adjusted through the outlet valve of the acetylene generator 101.

Embodiment 3

[0052] In a specific embodiment, in order to improve the purity of acetylene, the deuterated acetylene from the acetylene generator 101 passes through the buffer tank 102 and the flow meter 103, and then passes through the neutralization tanks 104-106 sequentially, using D 2 O, D 2 SO 4 and Na 2 S 2 o 3 The deuterated acetylene is washed with the solution, and the dust, NH 3 , S, As and other impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com