A kind of method for preparing mono-l-menthyl glutarate

A technology of glutaric acid mono-menthyl ester, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of low conversion rate, waste of raw materials, and many by-products, and achieve high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

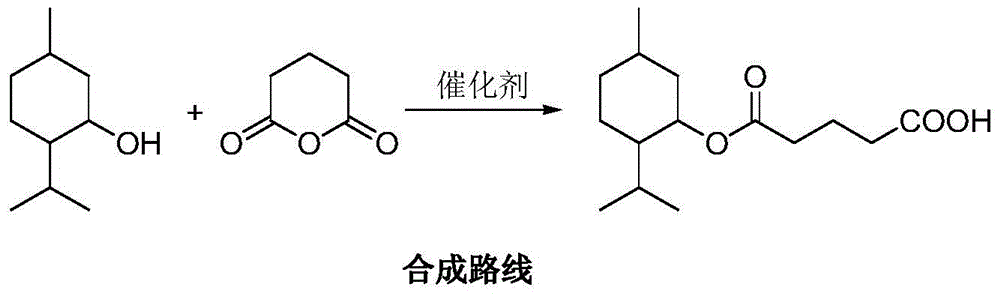

Image

Examples

Embodiment 1

[0015] Add glutaric anhydride 13.7g, menthol 15.6g artificial zeolite (Na 2 O·Al 2 o 3 · xSiO 2 ·yH 2 O) 3.2g, toluene 30ml. Gradually raise the temperature to 90°C, remove toluene by distillation under reduced pressure, react at 120°C for 4 hours, add 50ml of toluene after the reaction, add 200g of 5% sodium carbonate solution by mass, stir and separate layers, add 3N hydrochloric acid to the water layer, and adjust the pH value to 3 , stirred, extracted with ethyl acetate, dried the organic layer, filtered and distilled off the solvent under pressure, and dried to obtain 24.6g of glutaric acid mono-L-menthyl ester with a content of 98.7% and a menthol conversion rate of 91%.

Embodiment 2

[0017] Add glutaric anhydride 13.7g, menthol 15.6g artificial zeolite (BaO Al 2 o 3 · xSiO 2 ·yH 2 O) 3.2g, chloroform 25ml. Gradually raise the temperature to 90°C, remove chloroform by distillation under reduced pressure, react at 130°C for 5 hours, add 35ml of chloroform after the reaction, add 200g of 5% sodium carbonate solution by mass, stir and separate layers, add 3N hydrochloric acid to the water layer, and adjust the pH value to 3 , stirred, extracted with ethyl acetate, dried the organic layer, filtered and distilled off the solvent under pressure, and dried to obtain 24.1 g of mono-L-menthyl glutarate, with a content of 98.5% and a conversion rate of menthol of 89%.

Embodiment 3

[0019] Add glutaric anhydride 13.7g, menthol 15.6g artificial zeolite (K 2 O·Al 2 o 3 · xSiO 2 ·yH 2 O) 3.2g, butyl ether 40ml. Gradually raise the temperature to 90°C, remove butyl ether by distillation under reduced pressure, react at 90°C for 3.5 hours, add 55ml of butyl ether after the reaction, add 200g of 5% sodium carbonate solution by mass, stir and separate layers, add 3N hydrochloric acid to the water layer, and adjust the pH value 1, stirred, extracted with ethyl acetate, dried the organic layer, filtered and distilled off the solvent under pressure, and dried to obtain 23.5 g of mono-L-menthyl glutarate with a content of 98.7% and a conversion rate of menthol of 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com