Method for preparing dyeing accelerant from high liquid glauber salt

A technology of high nitrate water and dye accelerator, applied in the new technology of comprehensive utilization of dye accelerator for dyeing and finishing process, sodium sulfate and sodium chloride, can solve the problems of unfavorable environmental protection, high treatment cost, difficult treatment, etc. Improve the effect of promoting dyeing and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Experiment 1: The present invention will be further explained by specific examples below:

[0016] In each example, the pH value of the high nitrate water was adjusted to 5, and then heated to 80°C and kept for 2 hours to quickly decompose the solid impurities (especially impurities like calcium carbonate) in the high nitrate water, and then proceed to gradient After cooling down (10℃ / min) to normal temperature (25℃), the high nitrate water is filtered through a device similar to a microfiltration membrane to remove a small amount of insoluble matter, and finally the treated high nitrate water can be obtained, and then deionized Water can be used as a dye accelerant after mixing in a certain proportion.

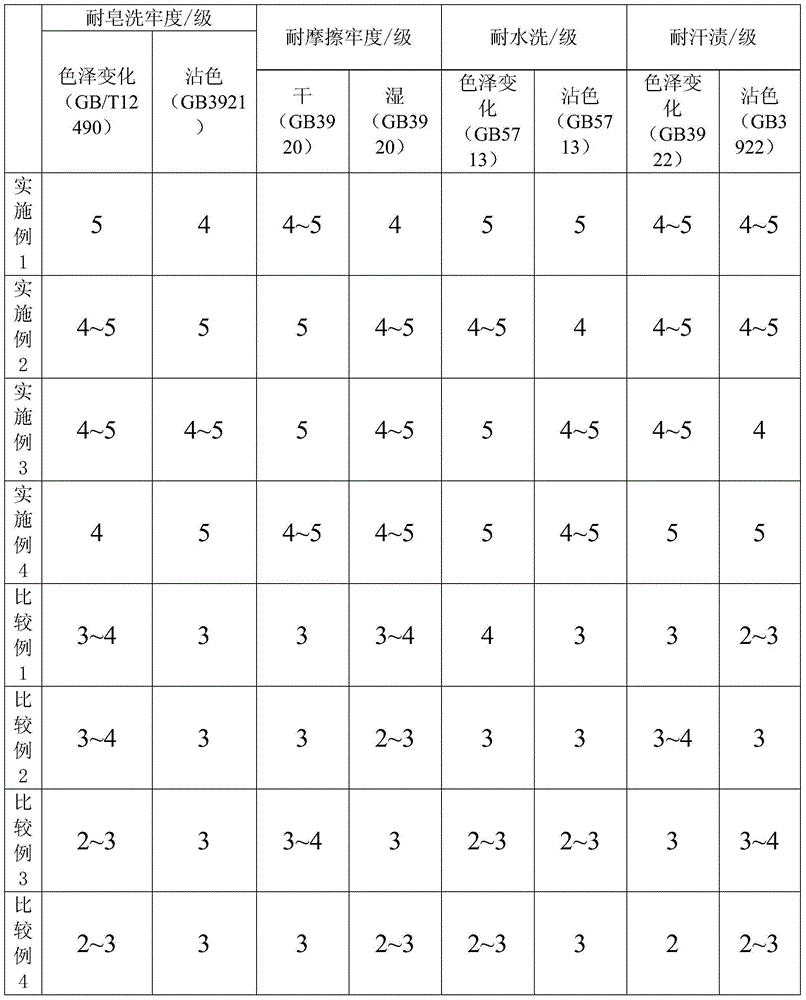

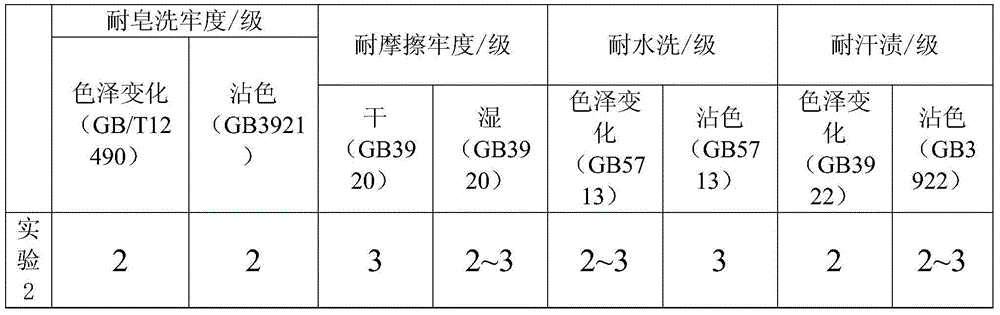

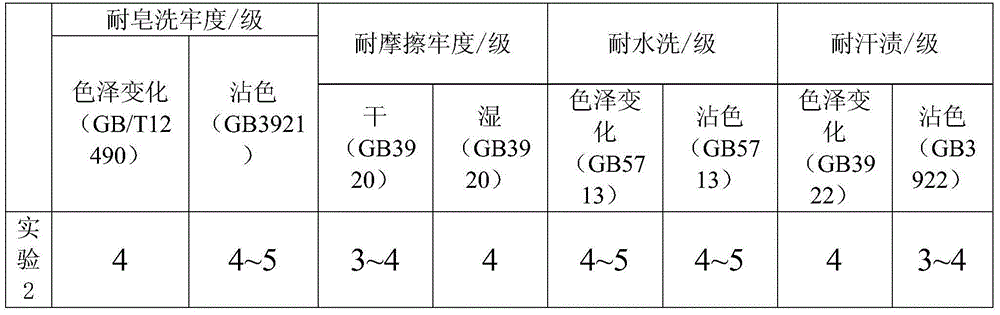

[0017] And the ratio of each component in the dye accelerator obtained in each example is shown in Table 1 (the unit of each content value in Table 1 is the mass concentration "g / L"):

[0018] Table 1

[0019]

Sodium chloride

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com