Ceramic tile combination applicable to external corner of wall and preparation method thereof

A technology for ceramic bricks and ceramic bricks, which is applied in the field of building ceramics, can solve the problems of difficulty in ensuring construction accuracy, unfavorable transportation and storage, and difficulty in construction, and achieves the effects of improving decorative effects, simple structure, and guaranteeing decorative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]

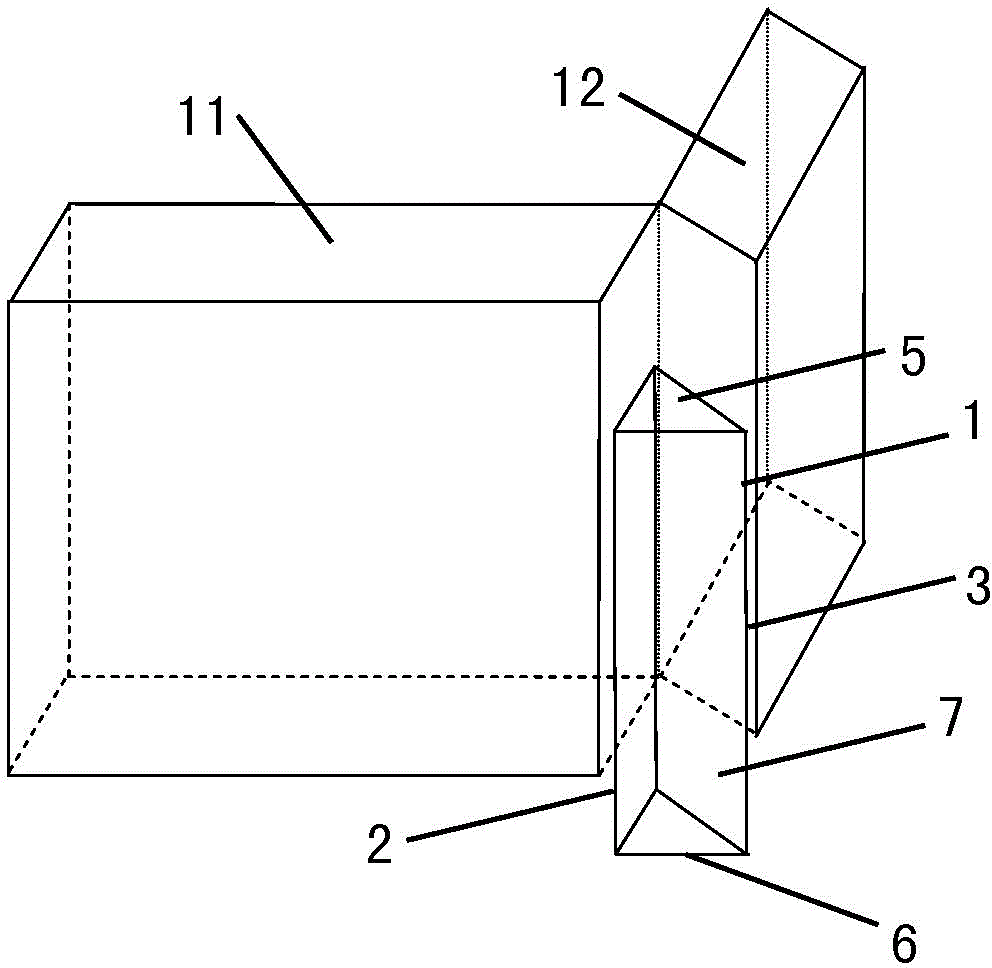

[0036]In the combination of ceramic tiles of the present invention, the external corner tiles of the wall body can adopt the same formula as that of the ceramic tile body of the wall body, extrusion molding, dry pressing molding, etc. can be used, and special molds can be used to press them into triangular shapes whose short sides are smaller than the thickness of the paving tiles. Body, cuboid, etc., after drying, adopt the same glazing, printing decoration process and pattern as wall bricks, and install them at the external corners of the wall after firing.

[0037] More specifically, as an example, the method for preparing the external wall corner tiles of the present invention may include the following steps.

[0038] Step 1: Make the ceramic blank slurry into a mud cake (for example, by using a vacuum mud mixer), and press and shape it into a wall ceramic brick body and an external corner ceramic brick body respectively. Press molding can adopt extrusion moldin...

Embodiment 1

[0043] The mineral composition of the green body formula used is 20% of medium temperature sand, 12% of Lihong potassium sand, 20% of Nanfeng low temperature sand, 12% of Quanzhou sodium stone, 7% of Bang sand, 6% of Lihong sand, and 5% of washed ball soil %, double cement 18%, wet ball milled into slurry after batching according to the formula, and smelted into mud cake with a mud mixer, and extruded wall ceramic brick body and external corner ceramic brick body by extrusion molding method. (Taking the specification of 800mm×800mm as an example and the thickness of 11mm as an example) the body of ceramic brick for the wall is a cuboid with a thickness of 11mm, a height of 800mm and a length of 800mm. The section of the positive angle ceramic brick body is an isosceles right triangle, and the length of the side of the right angle is consistent with the thickness of the wall ceramic brick body. After the green body is dried, the surface to be decorated of the wall ceramic brick...

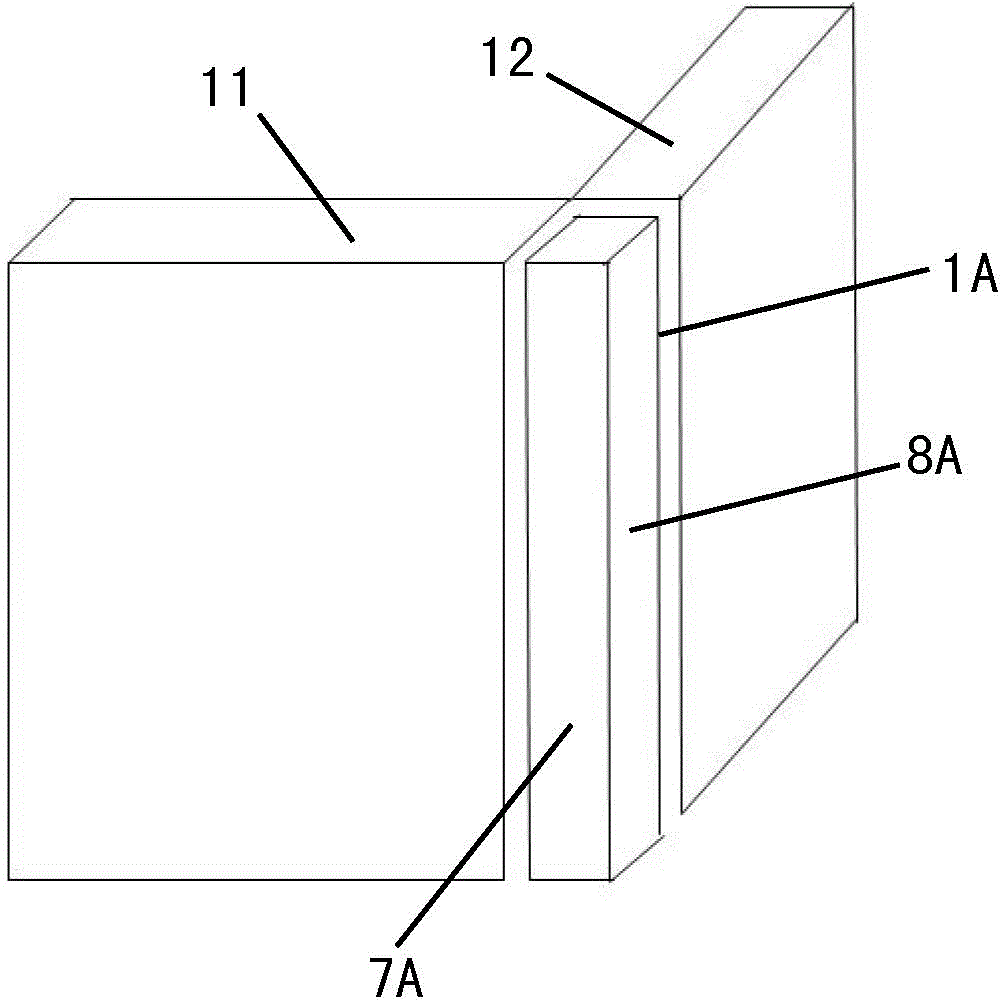

Embodiment 2

[0045] The mineral composition of the green body formula used is 20% of medium temperature sand, 12% of Lihong potassium sand, 20% of Nanfeng low temperature sand, 12% of Quanzhou sodium stone, 7% of Bang sand, 6% of Lihong sand, and 5% of washed ball soil %, double cement 18%, wet ball milled into slurry after batching according to the formula, and smelted into mud cake with a mud mixer, and extruded wall ceramic brick body and external corner ceramic brick body by extrusion molding method. (Taking the specification of 800mm×800mm as an example and the thickness of 11mm as an example) the body of ceramic brick for the wall is a cuboid with a thickness of 11mm, a height of 800mm and a length of 800mm. The body of the positive corner ceramic brick is a long columnar body with a square cross section, and the length is consistent with the length of the ceramic brick body of the wall. After the wall ceramic brick body and the positive corner ceramic brick body are placed on the V-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com