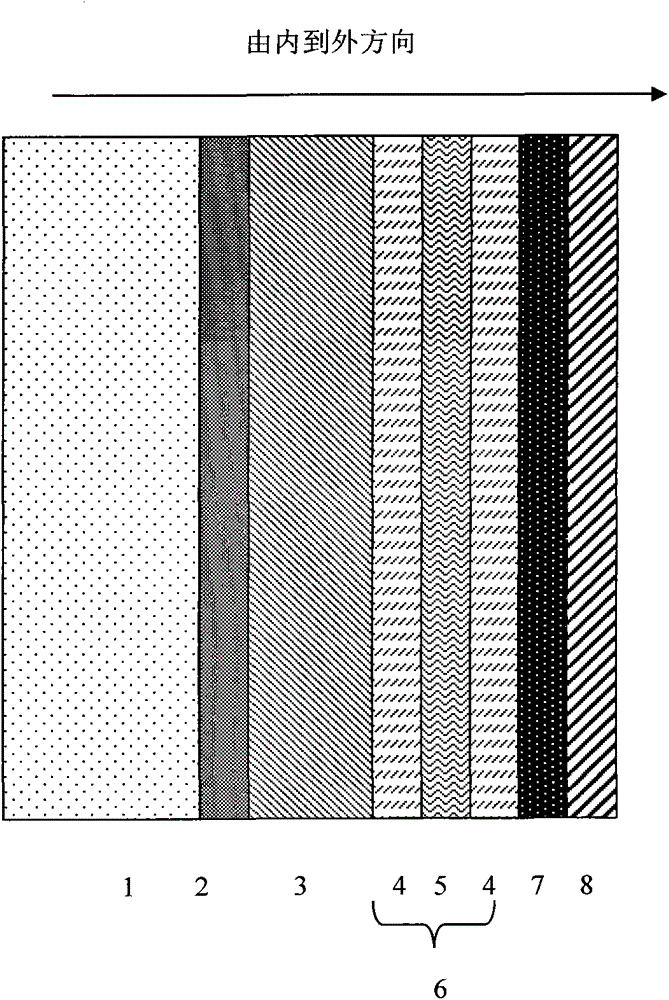

Construction technology of fireproof A<1>-stage inorganic internal and external wall insulation board

A technology of fire-proof insulation board and construction technology, which is applied in the direction of heat preservation, fire protection, and building material processing, etc., which can solve the problems of affecting the effect of anti-slip heat preservation, failing to meet the installation requirements, and unable to guarantee the installation effect, so as to enhance the overall strength and avoid the overall Effect of slipping and enhancing the life of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for installing a fireproof insulation board, comprising the steps of:

[0028] 1) Base wall treatment to remove surface dust;

[0029] 2) Pop out the horizontal line and install the base bracket: when installing, turn it from bottom to top, and you need to spring the line from the base, and fix the 30*50 wooden strips as the base and the bracket.

[0030] 3) Brush interface mortar

[0031] The construction of the fireproof board starts from the first floor, and the horizontal line is popped up 300mm from the ground. Use 1:3 cement mortar and add an appropriate amount of waterproofing agent as required, and paint the waterproof layer with the same thickness as the fireproof insulation board as a bracket;

[0032] 4) Paste the fire insulation board

[0033] Lay fire-proof insulation boards horizontally from bottom to top along the horizontal direction. The staggered seam between the upper and lower rows of insulation boards is 1 / 2 of the length of the board; 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com