Method for extracting residual coal bed gas in multiple layers of goafs by drilling well from ground and penetrating through residual coal pillars

A ground drilling and old goat technology, which is applied to earth drilling, mining fluids, mining equipment, etc., can solve the problems of difficult construction, inability to extract gas from multi-layer old goats at the same time, and low construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

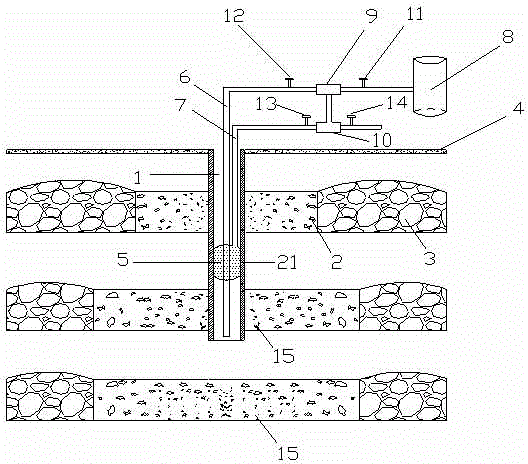

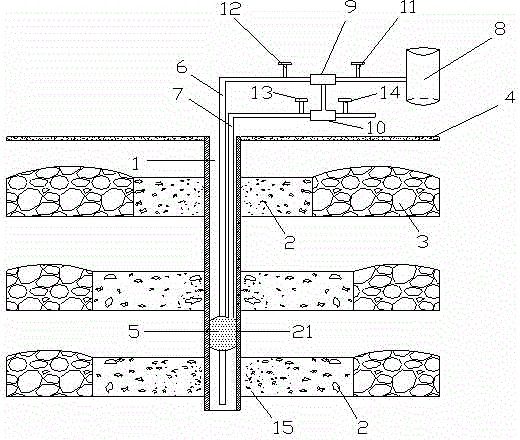

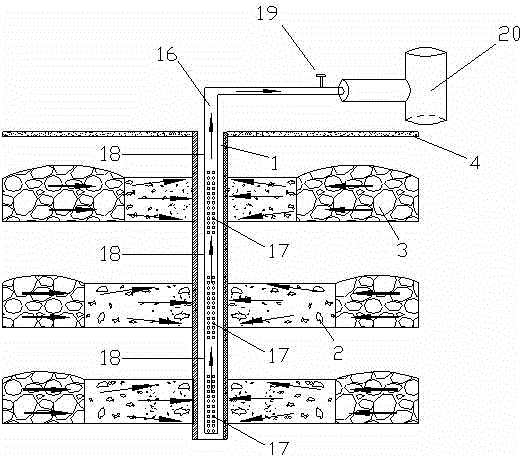

[0021] Below in conjunction with accompanying drawing, the example of the present invention will be further described:

[0022] The method for extracting residual coalbed methane in multi-layer old goaf area by ground drilling through residual coal pillars is characterized in that it includes the following content: constructing ground drilling from the ground to the center of the first layer of residual coal pillars, and penetrating down to the second layer At 0.5~1.5m of the floor of the residual coal pillar of the n layer, where 2≦n; the extraction pipe (16) is inserted from the ground (4) into the well (1), and the screen section (17) of the extraction pipe (16) is located At the residual coal pillar and extending 5m to the upper and lower parts of the residual coal pillar; after sealing the wellhead of the drilling (1), a fifth valve (19) is provided at the upper end of the extraction pipe (16) and connected to the pumping station (20); open The fifth valve (19) starts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com