Color coating line waste-gas-treating and heat-recovering method and system based on regenerative thermal oxidizer

A technology for waste gas treatment and color coating line, which is applied in combustion methods, incinerators, separation methods, etc., can solve the problems of high-grade energy waste, large energy consumption, and discharge into the atmosphere, saving energy, saving electricity, and reducing enterprises. the effect of spending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the description appropriate, simple and clear, the following will be described in conjunction with examples.

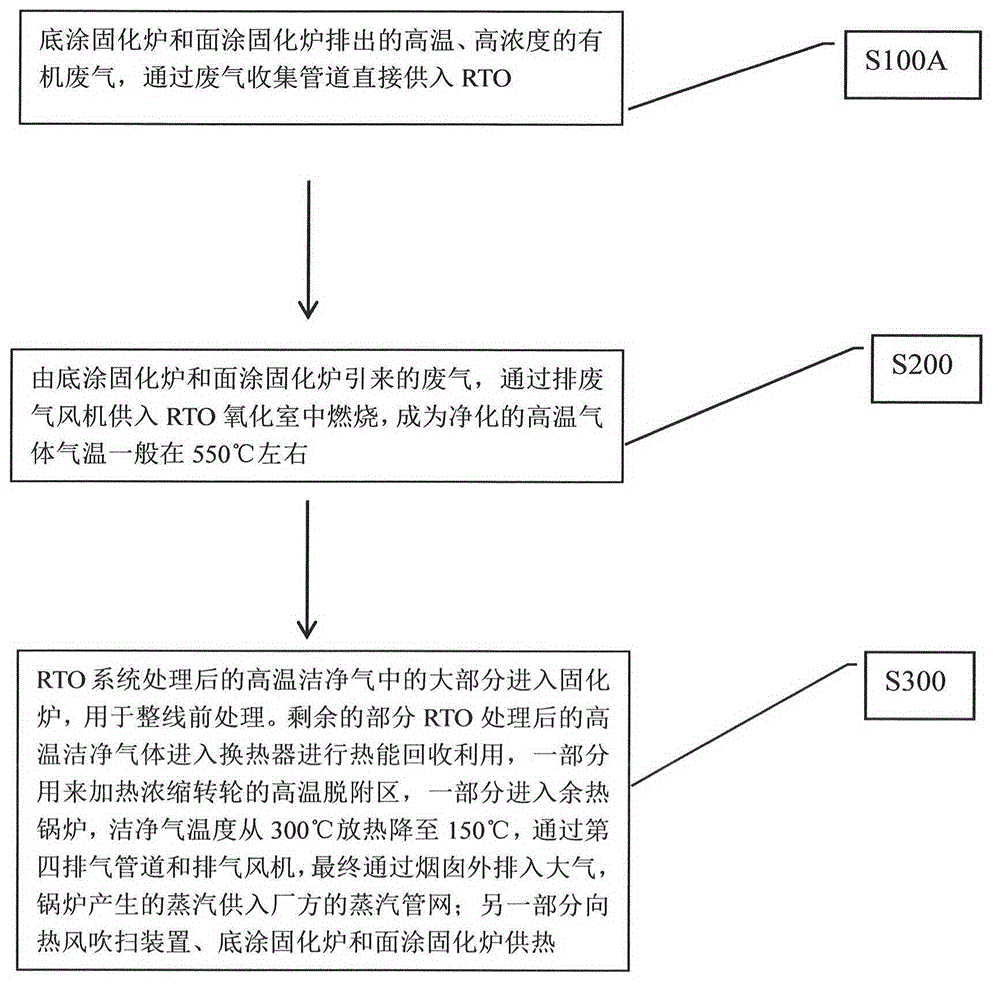

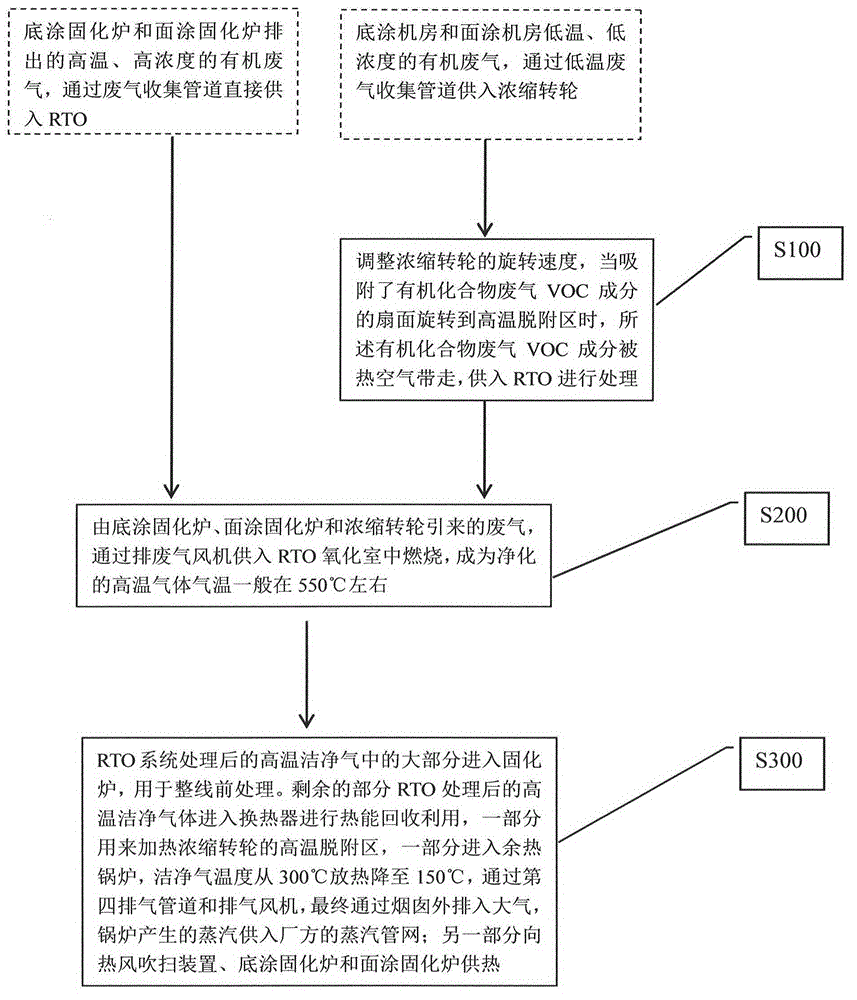

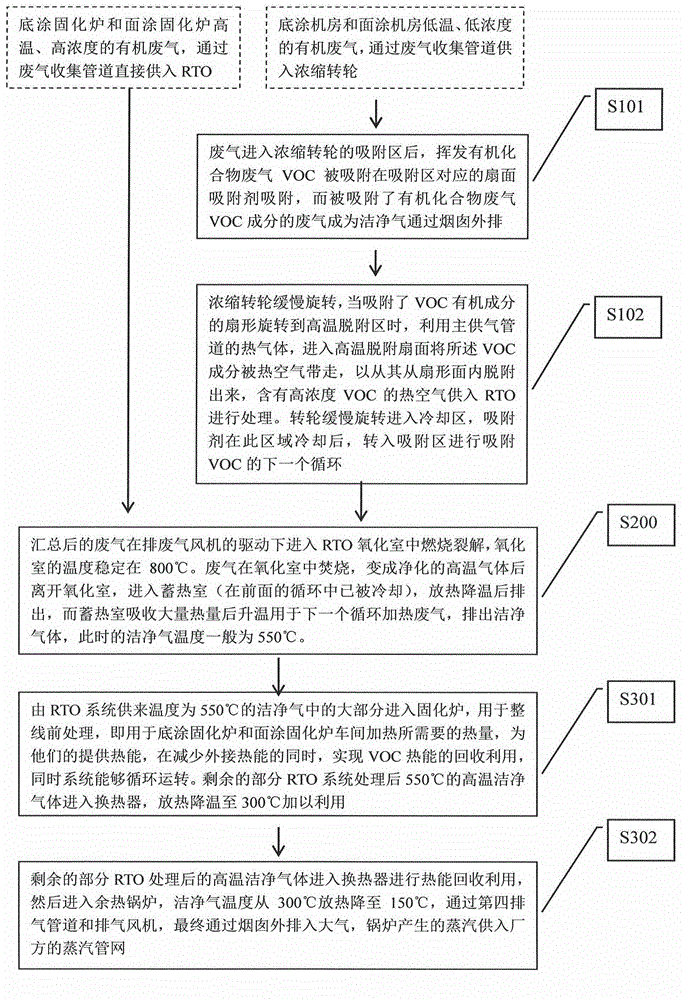

[0029] Reference attached figure 1 , using the regenerative incinerator (RTO) color coating production line waste gas treatment and waste heat utilization method, the low-temperature and low-concentration volatile organic compound waste gas discharged from the bottom coating machine room (1) and the top coating machine room (5) is passed through the low-temperature waste gas The collection pipe (8) and exhaust fan (9) are discharged outside the factory building through the chimney (33).

[0030] In step S100A, the high-temperature and high-concentration volatile organic compound waste gas discharged from the primer curing furnace (3) and the surface coating curing furnace (6) is sent to the regenerative incinerator (16) through the high-temperature waste gas collection pipe (7), usually It is an exhaust gas containing high concentration (8-12g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com