High-capacity RE-Mg-Ti-Ni-Co-Al system AB2 type hydrogen storage electrode alloy applied to Ni-MH batteries of hybrid electric vehicles and preparation method of alloy

A hybrid electric vehicle, re-mg-ti-ni-co-al technology, applied in the field of hydrogen storage alloy materials, can solve the problems of decreased reversible hydrogen absorption and desorption capacity of alloys, discharge capacity not exceeding, and no obvious hydrogen desorption platform , to achieve the effect of improving electrochemical cycle stability, reducing stability, and excellent electrochemical cycle stability

Active Publication Date: 2015-06-10

中稀(微山)稀土新材料有限公司

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In particular, the rare earth AB2 type hydrogen storage alloy fully meets the capacity requirements of hybrid electric vehicles in terms of its capacity, but there are still two problems in actual use: 1) Rare earth AB The actual discharge capacity of type 2 hydrogen storage alloy is much lower than the theoretical capacity. The theoretical capacity of this hydrogen storage alloy is 470 mAh / g, but the actual discharge capacity does not exceed 300 mAh / g. The actual discharge capacity of >2 type hydrogen storage alloy is one of the research directions

2) The hydrogen storage alloy system has a prominent hydrogen-induced amorphization phenomenon, which directly leads to the decline of the reversible hydrogen absorption and desorption capacity of the alloy.

Miyamura et al. prepared amorphous ReNi2 (Re = La, Ce, Pr, Mm) alloys by rapid quenching process, and their hydrogen absorption was higher than that of LaNi5 alloys. , but there is no obvious hydrogen release platform, and more than 75% of hydrogen cannot be released

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

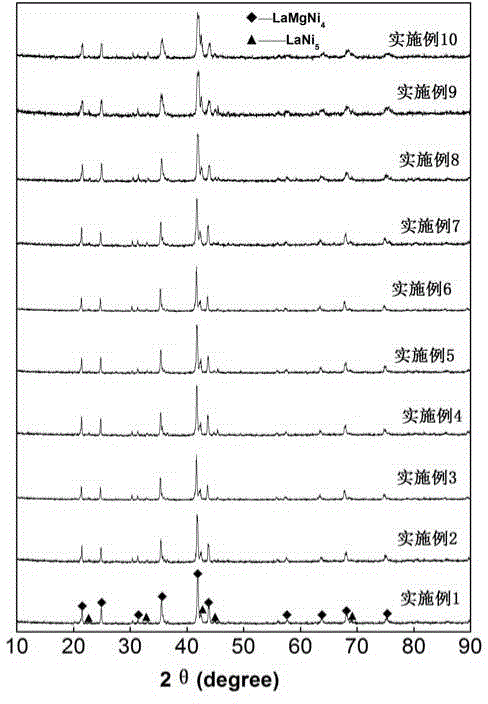

[0044] Example 1: La 0.8 Ce 0.1 Y 0.1 Mg 0.95 Ti 0.05 Ni 3.7 co 0.2 Al 0.1

Embodiment 2

[0045] Example 2: La 0.8 Ce 0.2 SM 0.2 Mg 0.95 Ti 0.05 Ni 3.7 co 0.2 Al 0.1

Embodiment 3

[0046] Example 3: La 0.7 PR 0.3 Mg 0.9 Ti 0.1 Ni 3.7 co 0.2 Al 0.1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

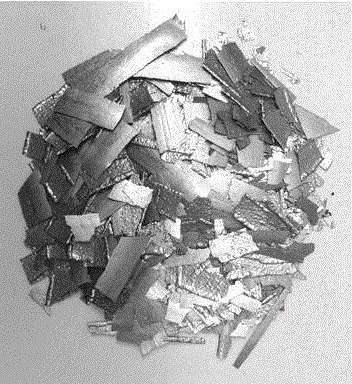

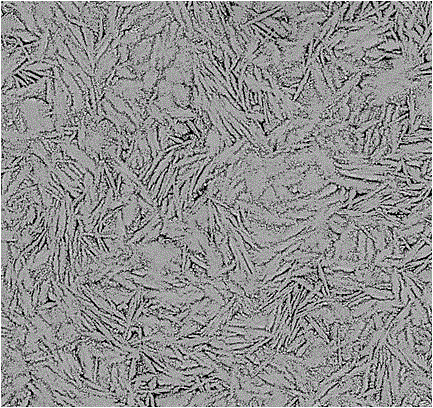

The invention relates to a high-capacity RE-Mg-Ti-Ni-Co-Al system AB2 type hydrogen storage electrode alloy applied to Ni-MH batteries of hybrid electric vehicles. The chemical composition of the alloy is La1-xRExMg1-yTiyNi4-z-mCozAlm, wherein the chemical component of an A side element is La1-xRExMg1-yTiy; the chemical component of a B side element is Ni4-z-mCozAlm; x, y, z and m in the formula are atomic ratios; x is larger than or equal to 0.1 and smaller than or equal to 0.4; y is larger than or equal to 0.01 and smaller than or equal to 0.1; z is larger than or equal to 0.1 and smaller than or equal to 0.3; m is larger than or equal to 0.05 and smaller than or equal to 0.2; RE is selected from at least one of Ce, Sm, Y, Nd and Pr except La. A preparation method of the high-capacity RE-Mg-Ti-Ni-Co-Al system AB2 type hydrogen storage electrode alloy comprises the following steps: sensing, heating and smelting in vacuum and carrying out inert gas protection to prepare a uniform and consistent quickly-quenched alloy sheet, annealing a small quantity of amorphous phases formed by quickly quenching, and then thoroughly crystallizing the amorphous phases, thereby effectively inhibiting hydrogen-inducing amorphization phenomenon in the subsequent electrochemical process of absorbing and desorbing hydrogen. With combination of the component design and the preparation process, the electrochemical hydrogen storage property of the alloy is improved; the process is easy to master and is suitable for large-scale production; the maximum discharge capacity of the prepared alloy is 435mAh / g, which is 92% of the theoretical discharge capacity; the obvious hydrogen-inducing amorphization phenomenon is not found after performing electrochemical charging and discharging cycle for 300 times.

Description

Technical field [0001] The present invention is a technology field in hydrogen storage alloy materials, and specially involves a high-capacity RE-MG-TI-CO-CO-AL system that is suitable for hybrid vehicles NI-MH batteries 2 Hydrogen storage electrode alloys and preparation methods. Background technique [0002] With the rapid development of hybrid vehicles, the electrochemical properties of nickel-metal hydrogen (NI-MH) batteries have put forward higher requirements, especially energy density, and then proposed to the negative electrode material of the NI-MH battery-hydrogen storage alloyHigh -capacity requirements.At present, my country has realized commercial Ni-MH battery negative materials mainly about rare earth base AB 5 Hydrogen storage alloys (its A -side element refers to the permanent metal element that can form stable hydrogenia with hydrogen, such as rare earth element RE, TI, ZR, MG, V, etc.However, heat -absorbing metal elements with hydrogen catalytic activity, such...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/38

CPCH01M4/383H01M2004/027H01M2220/20Y02E60/10

Inventor 高金良张羊换尚宏伟杨泰翟亭亭李亚琴

Owner 中稀(微山)稀土新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com