Manufacturing method for increasing effective photosensitive area of photoelectric material

A photosensitive area and photoelectric material technology, which is applied in the field of preparation of multi-period micro-nano composite structures, can solve the problems of not being suitable for mass production, strict use conditions, poor uniformity, etc., and achieve improved photoelectric conversion efficiency, increased contact area, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

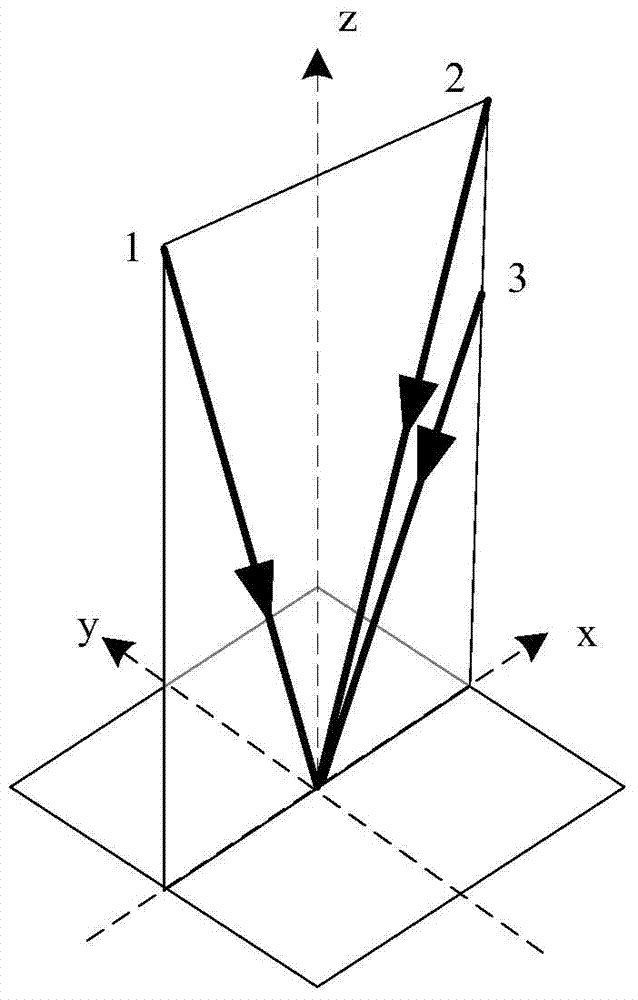

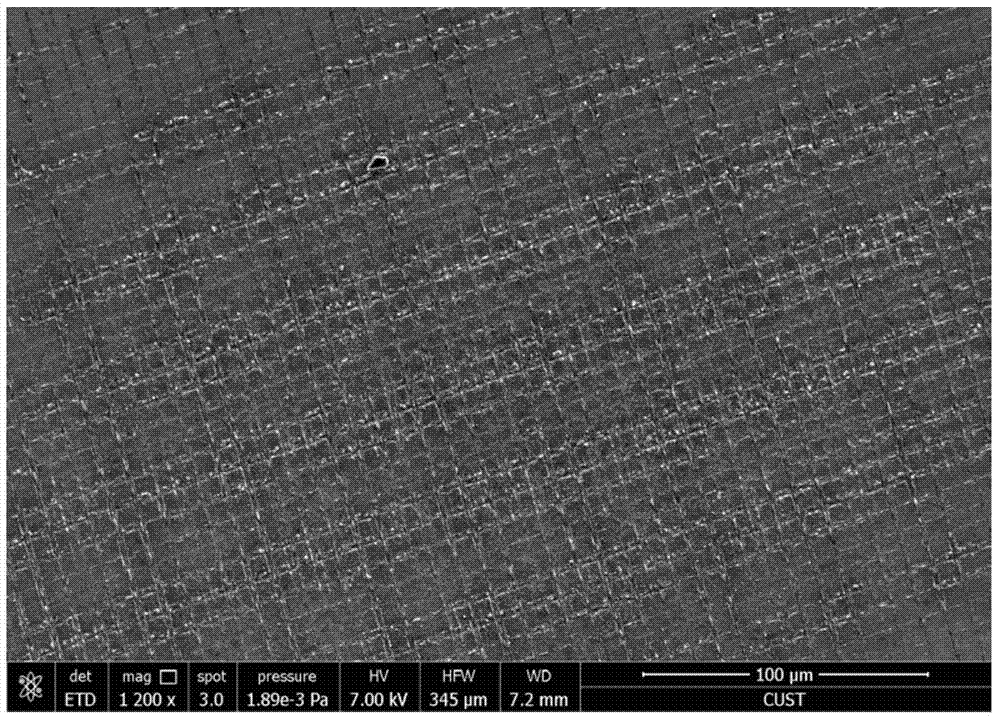

[0024] Using the optical path of the three-beam laser interference system, the laser wavelength is 1.064μm, the energy density of each beam is 0.64J / cm2, and the pulse width is 6ns. The incident mode of the three laser beams is as follows figure 1 As shown, the incident angles of beam 1 and beam 2 are both 7°, the incident angle of beam 3 is 14°, the spatial angle of beam 1 is 0°, the spatial angle of beam 2 and beam 3 is 180°, the three beams The polarization state is the same, and the polished single crystal silicon surface is exposed for 10s. After the first exposure is completed, the rotating table is rotated 90° clockwise for the second exposure. The exposure time is 8s, and the following is obtained: image 3 The square composite structure has a side length of 4.4 μm, a structure depth of 0.2-1 μm, a modulation period of 8.7 μm, and a 15% increase in the surface area of the material.

Embodiment 2

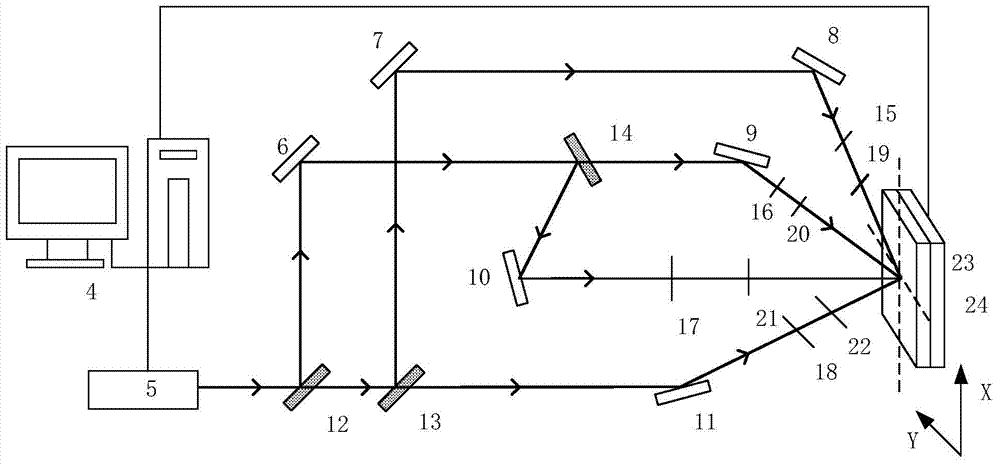

[0026] The optical path of the four-beam laser interference system is as follows: figure 2 As shown, the laser wavelength is 1.064μm, the energy density of each beam is 0.64J / cm2, the pulse width is 6ns, the incident angle of the four beams is 8°, and the space angles of the four beams are 0°, 90°, 180 °, 270°, the exposure time on the surface of polished single crystal silicon material is 5s, and the obtained Figure 4 The lattice structure shown is similar to a raised hemisphere with a period of 4 μm, the size of a single protrusion is 2-2.5 μm, the depth of the structure is 0.1-0.32 μm, and the surface area of the material is increased by 30%.

[0027] In a word, the present invention utilizes modulating laser interference lithography technology to directly prepare a multi-period micro-nano composite structure on the surface of a matrix material or a photosensitive material, and adds a three-dimensional optical contact surface within a two-dimensional unit plane area. Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com