Micro-plasma arc discharge catalyzed water treatment method utilizing alternating-current power source

A technology of micro-plasma and AC power supply, applied in the direction of electrochemical water/sewage treatment, etc., can solve the problems of small reaction area, fast anode corrosion, and low efficiency, and achieve the effects of alleviating electrode corrosion, easy access, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

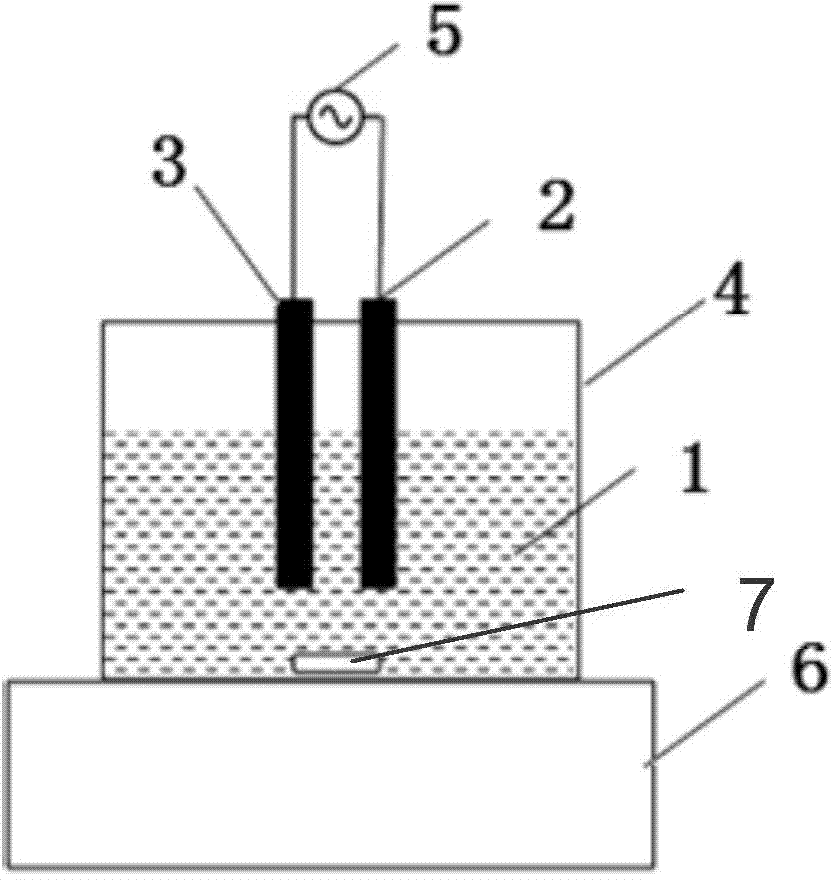

[0051] A method for treating water with micro-plasma arc discharge catalyzed by AC power supply has the following steps:

[0052] 1) Add additives to the liquid to be treated 1;

[0053] 2) Turn on the ventilation system and magnetic stirring system 6;

[0054] 3) Insert electrode I2 and electrode II3 into the reaction cell 4;

[0055] 4) Add the liquid to be treated 1 containing additives into the reaction tank 4;

[0056] 5) Switch on the power supply between the electrode I2 and the electrode II3, and gradually increase the voltage so that the power supply discharges stably under the parameters of the power supply;

[0057] 6) Analyze the water treatment effect: take regular samples to test the water quality change of the liquid to be treated 1, calculate the treatment time in advance, and combine the test results to determine the end of the treatment;

[0058] 7) End of water treatment: After gradually reducing the power supply voltage to 10-20V, turn off the power supply, the magneti...

Embodiment 2

[0069] A method for treating water with micro-plasma arc discharge catalyzed by AC power supply has the following steps:

[0070] 1) Add additives to the liquid to be treated 1;

[0071] 2) Turn on the ventilation system and magnetic stirring system 6;

[0072] 3) Insert electrode I2 and electrode II3 into the reaction cell 4;

[0073] 4) Add the liquid to be treated 1 containing additives into the reaction tank 4;

[0074] 5) Switch on the power supply between the electrode I2 and the electrode II3, and gradually increase the voltage so that the power supply discharges stably under the parameters of the power supply;

[0075] 6) Analyze the water treatment effect: take regular samples to test the water quality change of the liquid to be treated 1, calculate the treatment time in advance, and combine the test results to determine the end of the treatment;

[0076] 7) End of water treatment: After gradually reducing the power supply voltage to 10-20V, turn off the power supply, the magneti...

Embodiment 3

[0086] A method for treating water with micro-plasma arc discharge catalyzed by AC power supply has the following steps:

[0087] 1) Add additives to the liquid to be treated 1;

[0088] 2) Turn on the ventilation system and magnetic stirring system 6;

[0089] 3) Insert electrode I2 and electrode II3 into the reaction cell 4;

[0090] 4) Add the liquid to be treated 1 containing additives into the reaction tank 4;

[0091] 5) Switch on the power supply between the electrode I2 and the electrode II3, and gradually increase the voltage so that the power supply discharges stably under the parameters of the power supply;

[0092] 6) Analyze the water treatment effect: take regular samples to test the water quality change of the liquid to be treated 1, calculate the treatment time in advance, and combine the test results to determine the end of the treatment;

[0093] 7) End of water treatment: After gradually reducing the power supply voltage to 10-20V, turn off the power supply, the magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com