Rotary cage net type electric flocculation reactor

An electro-flocculation and rotating cage technology, applied in chemical instruments and methods, light water/sewage treatment, energy and wastewater treatment, etc., can solve the problems of high operating costs, anode consumption, anode passivation, etc., and achieve improved flocculation efficiency and increase Contact area and contact time, effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

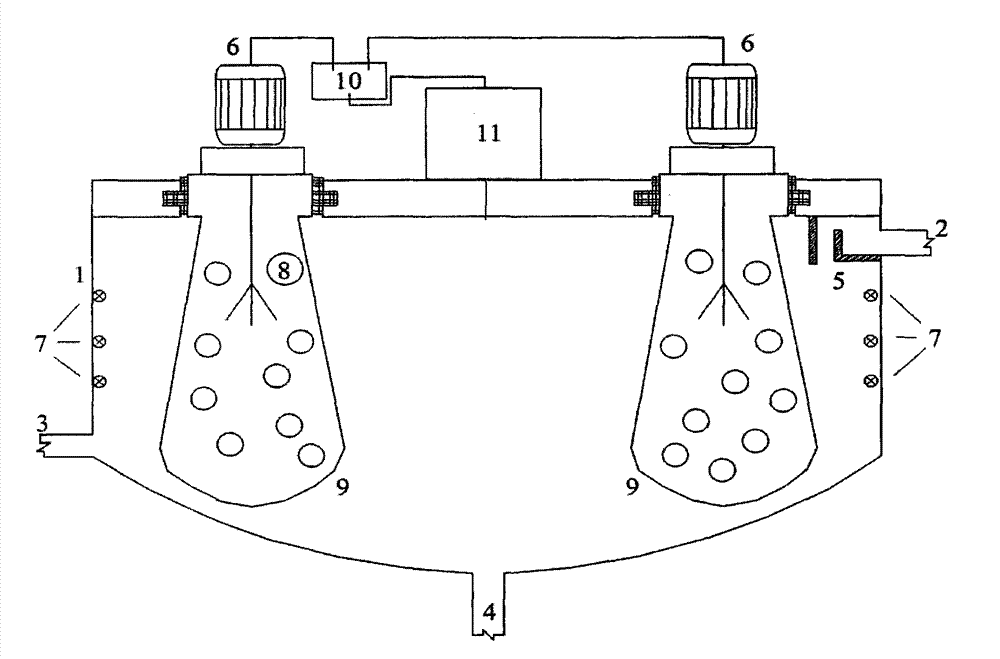

[0025] Such as figure 1 As shown, the rotating cage net type electrocoagulation reactor of the present invention includes electrocoagulation reaction tank 1, water inlet pipe 2, water outlet pipe 3, floc discharge pipe 4, water inlet retaining wall 5, ultraviolet lamp 7, rotating cage net type Filling electrode 9, variable frequency motor 6 and controller 10;

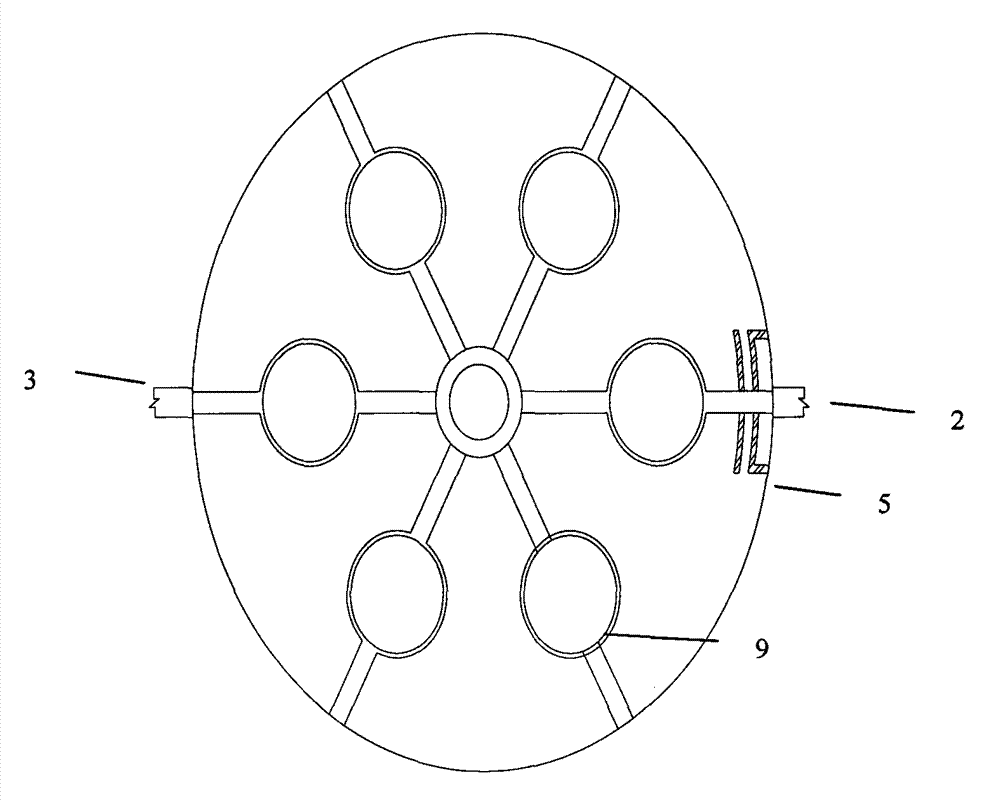

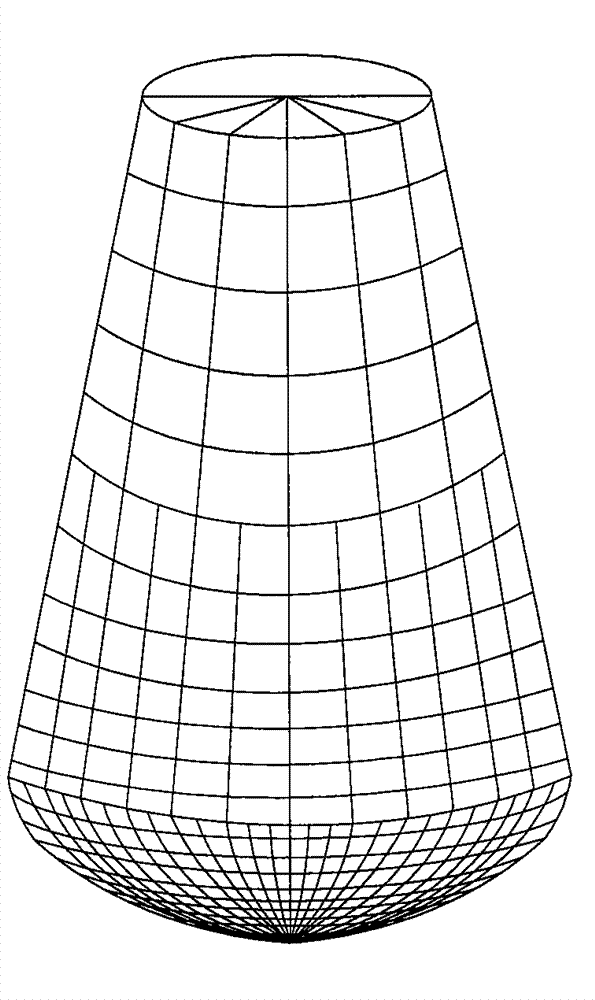

[0026] Wherein the electrocoagulation reaction tank 1 comprises a circular funnel-shaped pool body, the pool body diameter is 3m, the height of the cylinder is 2m, and the height of the lower cone is 1m; figure 2 ), each steel frame is provided with a rotating cage-type filler electrode 9, and the top of the electrode is riveted with the steel frame structure with bolts; There is an outlet pipe 3, and the bottom of the electrocoagulation reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com