Calcium carbonate recovery-based integrated underground water hardness removal device

A calcium carbonate and groundwater technology, which is applied in the treatment of polluted groundwater/leachate, chemical instruments and methods, and multi-stage treatment of water/sewage. It can solve the problem of high residual concentration of calcium and magnesium ions, incomplete reaction, waste Difficulty in disposal and other problems, to achieve a wide range of applications, improve the treatment effect and overall effluent quality, and improve the prospects for promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

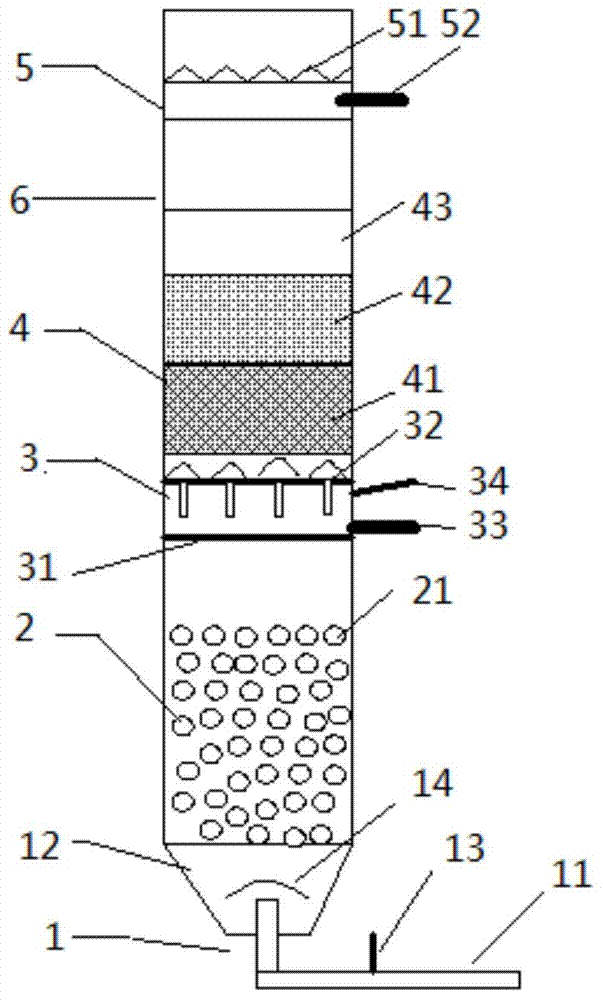

[0023] The integrated groundwater hardness removal device based on calcium carbonate recovery of the present invention will be further described below in conjunction with the accompanying drawings.

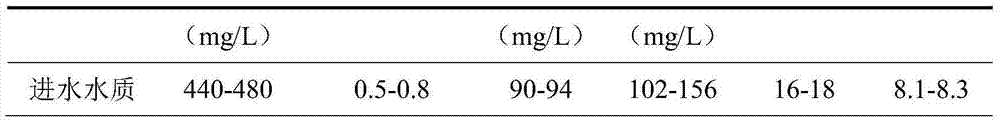

[0024] Integrated groundwater hardness removal device based on calcium carbonate recovery, see figure 1 , including a housing 6 and a water inlet unit 1, a calcium carbonate enrichment recovery unit 2, an air-water combined backwash unit 3, a filter unit 4 and a water outlet unit 5, which are sequentially arranged in the housing 6 from bottom to top; The unit 1 includes a water inlet pipe 11 and a mixing device 12; the water inlet pipe 11 is provided with a hardness removal agent dosing port 13; the water outlet of the water inlet pipe 11 is arranged inside the mixing device 12, and the upper end of the water inlet pipe 11 is provided with an inverted arc Shaped water baffle 14; Calcium carbonate recovery unit 2 comprises a group of gathering columns 21 arranged in parallel, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com