Polyethylene terephthalate composite material and preparation method thereof

A technology of polyethylene terephthalate and composite materials, which is applied in the field of composite materials, can solve the problems of PET molecular weight reduction, mechanical property degradation, PET molecular chain breakage, etc., to improve wettability, increase crystallization rate, and improve Effect of crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

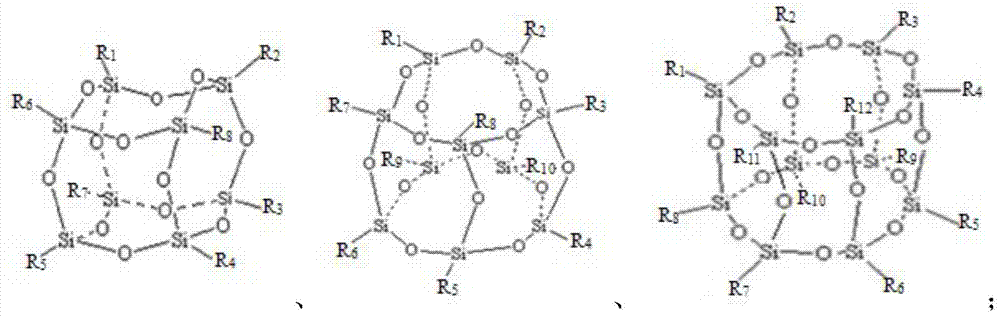

[0028] The preparation method of polyethylene terephthalate composite material of the present invention may further comprise the steps:

[0029] Step 1, mixing 1 to 5 parts by weight of dried polyhedral oligosilsesquioxane and 100 parts by weight of dried polyethylene terephthalate in a high-speed mixer to obtain a mixed material;

[0030] Step 2, adding the mixed material into a twin-screw extruder, extruding at 220-260°C, cooling the obtained strands with water, and granulating with a pelletizer to obtain pellets;

[0031] Wherein, there is no special limitation on the size of the strips and pellets, and they can be prepared according to the requirements of extrusion molding in the prior art;

[0032] Step 3, drying the pellets at 100-140°C until the moisture content is below 0.02%, to obtain a polyethylene terephthalate composite material;

[0033] Wherein, there is no lower limit for the moisture content after drying, and it can be determined as required.

[0034] The PO...

Embodiment 1

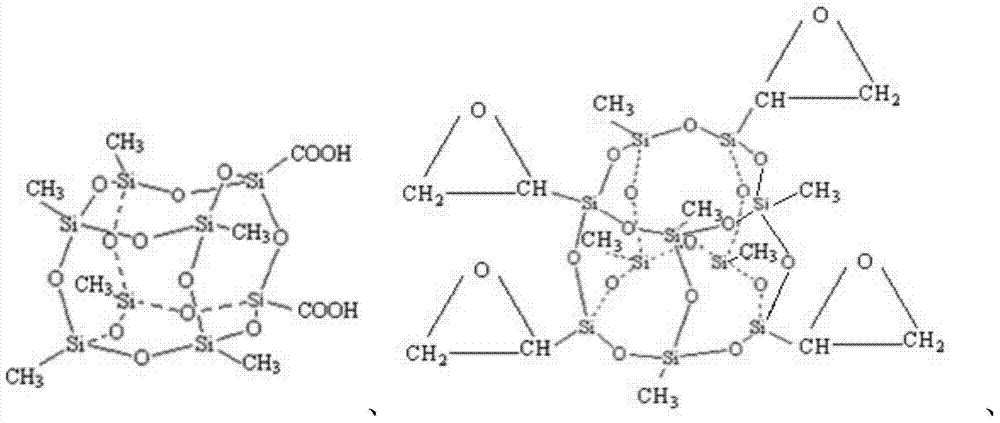

[0044] Polyethylene terephthalate composite material, by the drying of 100 parts by weight of PET and 1 part by weight of T 8 Type POSS composition, among them, the T with two carboxyl groups 8 The structural formula of type POSS is as follows:

[0045]

[0046] The preparation of above-mentioned polyethylene terephthalate composite material:

[0047] The above-mentioned 1 part by weight of T 8 Type POSS and 100 parts by weight of dried PET are put into a high-speed mixer and mixed evenly to obtain a mixed material, and then the mixed material is added to a twin-screw extruder and extruded at 220-260 ° C After the strips are cooled by water, they are granulated by a granulator, and the obtained granules are dried at 140° C. until the moisture content is less than 0.02%, to obtain polyethylene terephthalate composite materials.

[0048] The molecular weight of the polyethylene terephthalate composite material obtained in Example 1 is detected by gel chromatography, and th...

Embodiment 2

[0050] Composite polyethylene terephthalate consisting of 100 parts by weight of oven-dried PET and 2 parts by weight of oven-dried T 10 Type POSS composition, wherein, T with four epoxy groups 10 The structural formula of type POSS is as follows:

[0051]

[0052] The preparation of above-mentioned polyethylene terephthalate composite material:

[0053] The T with four epoxy groups of the above-mentioned 2 parts by weight of drying 10 Type POSS and 100 parts by weight of dried PET are put into a high-speed mixer and mixed evenly to obtain a mixed material, and then the mixed material is added to a twin-screw extruder and extruded at 220-260 ° C After the strips are cooled by water, they are granulated by a granulator, and the obtained granules are dried at 140° C. until the moisture content is less than 0.02%, to obtain polyethylene terephthalate composite materials.

[0054] Detect the molecular weight of the polyethylene terephthalate composite material obtained in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com