A two-stage catalytic gasoline upgrading method for producing ultra-low sulfur gasoline by increasing gasoline yield

A technology for catalytic gasoline and catalytic cracking gasoline, which is applied in the fields of hydrocarbon oil treatment products, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of large gasoline yield loss and achieve small octane loss, no loss of gasoline yield or increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

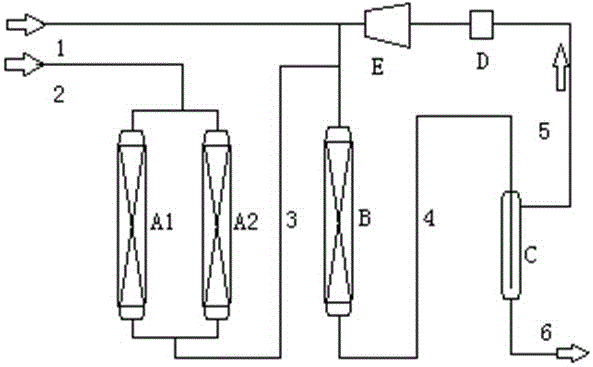

Image

Examples

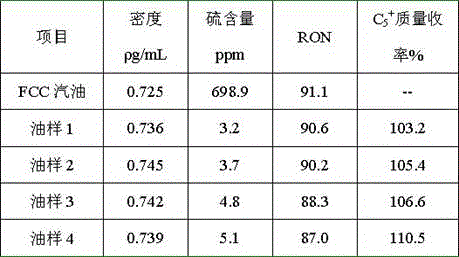

Embodiment 1~4

[0036] The composition of the raw oil is a mixture of 85% by volume of full-cut FCC gasoline and 15% by volume of C4 liquefied gas. Fill the alkylation section with 5mL nanometer Hβ-γ-Al 2 o 3 Catalyst, obtained by modifying the catalyst with 0.5mol / L citric acid in a water bath at 85°C for 3 hours, filled with 5mL Co-Mo / ZSM-5-MCM-41 in the fixed bed of the hydrodesulfurization / aromatization section, and the carrier ZSM-5 / MCM The mass ratio of ZSM-5 to MCM-41 in -41 composite molecular sieve is 7:3, the active components CoO, MoO 3 The loading amounts were 2.0% and 5.0% of the carrier mass, respectively. The reaction conditions in the alkylation section are bed temperature 90°C, hydrogen to oil volume ratio 10, system pressure 1.5MPa, liquid hourly space velocity 2h -1 ;The reaction conditions of hydrodesulfurization / aromatization section are hydrogen oil volume ratio 300, system pressure 1.5MPa, liquid hourly space velocity 2h -1 , and the bed temperatures were 410°C, 390...

Embodiment 5

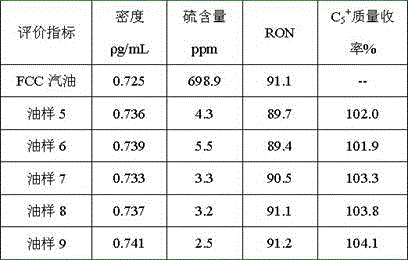

[0041] Change the hydrogen oil volume ratio in the hydrodesulfurization / aromatization section to 240, and other conditions and parameters are the same as in Example 1 to obtain oil sample 5.

Embodiment 6

[0043] Change the hydrogen oil volume ratio in the hydrodesulfurization / aromatization section to 360, and other conditions and parameters are the same as in Example 1 to obtain oil sample 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com