A method for preparing and recovering sponge copper metal from pickling sludge

A technology for pickling sludge and sponge copper, which is applied in the direction of improving process efficiency, can solve the problems of reduction, harmlessness and resource utilization of sludge that cannot be pickled, and achieves zero discharge and preparation. Simple recycling process and great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

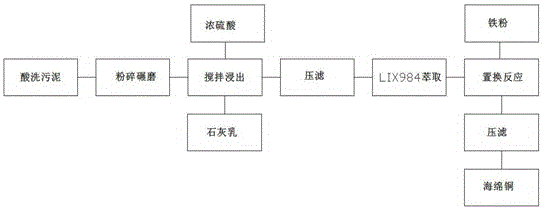

[0023] Such as figure 1 The present invention as shown provides a method for preparing and recovering sponge copper metal from pickling sludge, comprising the following steps, step 1, pulping, pulverizing the pickling sludge with a pulverizer, adding water and stirring to form a slurry evenly , the water content concentration is 10%-20%, among them, adding water industrial water, including river water, well water, surface recycling water. Step 2, stirring and leaching, first add concentrated sulfuric acid to the slurry pickling sludge in step 1, stir while adding until the pH value of the slurry pickling sludge is 1-2, then add milk of lime, and stir while adding until The pH value of slurry pickling sludge is 2-3.5. Step 3. Perform a pressure filtration treatment on the leach residue in step 2 to obtain a filter residue and a filtrate, and the filtrate enters the next process step. Step 4, to the filtrate of step 3, utilize LIX984 extraction agent to carry out extraction tr...

Embodiment 2

[0026] Such as figure 1 The present invention as shown provides a method for preparing and recovering sponge copper metal from pickling sludge, comprising the following steps, step 1, pulping, pulverizing the pickling sludge with a pulverizer, adding water and stirring to form a slurry evenly , the water content concentration is 10%-15%, among them, adding water industrial water, including river water, well water, ground recovery water. Step 2, stirring and leaching, first add concentrated sulfuric acid to the slurry pickling sludge in step 1, and stir while adding until the pH value of the slurry pickling sludge is 1-1.5, then add milk of lime, and stir while adding until The pH value of slurry pickling sludge is 2.5-3. Step 3. Perform a pressure filtration treatment on the leach residue in step 2 to obtain a filter residue and a filtrate, and the filtrate enters the next process step. Step 4, to the filtrate of step 3, utilize LIX984 extraction agent to carry out extractio...

Embodiment 3

[0029] Such as figure 1The present invention as shown provides a method for preparing and recovering sponge copper metal from pickling sludge, comprising the following steps, step 1, pulping, pulverizing the pickling sludge with a pulverizer, adding water and stirring to form a slurry evenly , the water content concentration is 12%-14%, among them, adding water industrial water, including river water, well water, surface recycling water. Step 2, stirring and leaching, first add concentrated sulfuric acid to the slurry pickling sludge in step 1, and stir while adding until the pH value of the slurry pickling sludge is 1.2-1.4, then add lime milk, and stir while adding until The PH value of slurry pickling sludge is 2.6-2.8. Step 3. Perform a pressure filtration treatment on the leach residue in step 2 to obtain a filter residue and a filtrate, and the filtrate enters the next process step. Step 4, to the filtrate of step 3, utilize LIX984 extraction agent to carry out extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com