Linear motor rotor position measuring method

A linear motor and mover position technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult maintenance, high price, high requirements for the working environment of grating sensors, etc., and achieve the effect of low correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

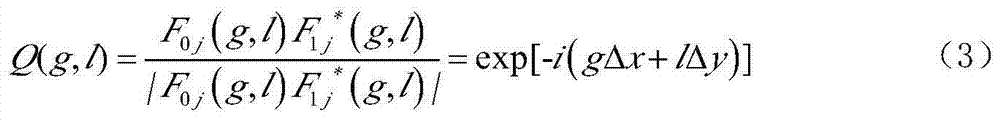

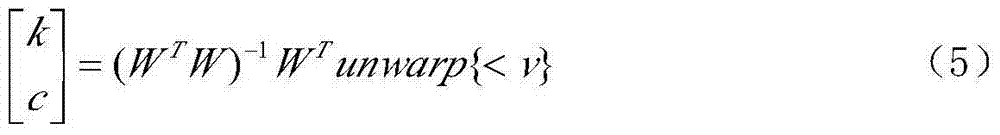

[0038]In this embodiment, the method for measuring the position of the mover of the linear motor is carried out according to the following steps:

[0039] Step a. Construct a reference image

[0040] Construct a reference image on the base of the linear motor, the gray value of the reference image gradually changes along the direction of the movement of the motor mover, and the gray value is the same along the direction perpendicular to the movement of the motor mover; the size of the reference image is A×B, and the gray value matrix r is expressed as [b 1 ,b 2 ,...,b B ], b i It is a row and column vector of A, and the elements of the column vector are all i, i={1,2,...,B}; perform gamma transformation on the gray value matrix r, and obtain the transformed gray value matrix s, s=cr γ , wherein c=1, γ=2.5, the digital image corresponding to the transformation gray value matrix s is used as a reference image;

[0041] As a two-dimensional information source, considering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com