A low optical loss mems thermo-optic tunable filter

A tunable filter and optical loss technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problem of high optical loss of thermo-optic tunable filters, and achieve the improvement of filter waveforms that cannot meet the application, good application prospects, and low extinction The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

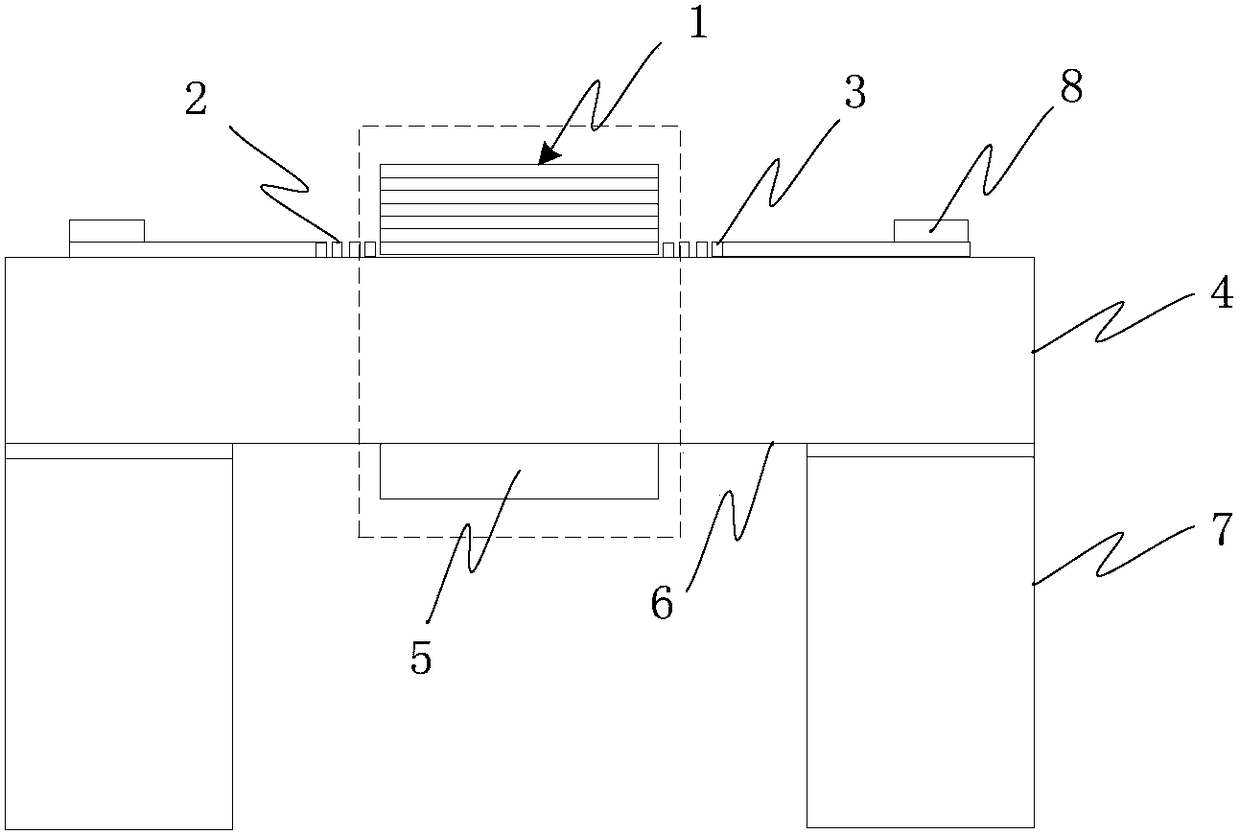

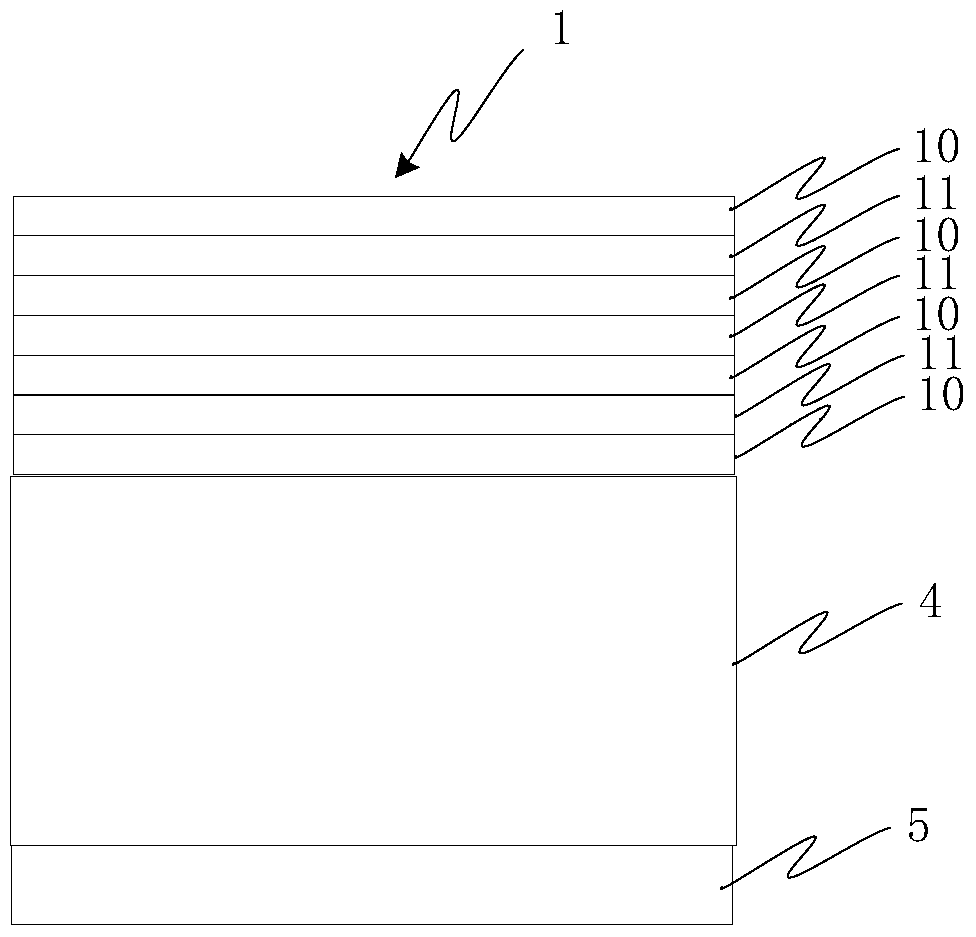

[0037] Such as Figure 1 ~ Figure 3 As shown, the present invention provides a MEMS thermo-optic tunable filter with low optical loss, and the MEMS thermo-optic tunable filter comprises a multi-cavity optical fiber whose half-wave resonant cavity adopts AlN or GaN thermo-optic tunable dielectric film material 11 The interference thin film filter layer 1 and the micro heater 2 can adjust the central wavelength of the MEMS thermo-optic tunable filter by controlling the operating current of the micro heater 2 .

[0038] Such as figure 1As shown, the MEMS thermo-optic tunable filter in this embodiment includes: a multi-cavity optical interference thin film filter layer 1, a single crystal silicon support film 4, a single crystal silicon suspension beam 6, an optical antireflection film 5, and a silicon substrate 7. Micro heater 2, micro temperature sensor 3 and lead wire pad 8.

[0039] Wherein, the multi-cavity optical interference thin film filter layer 1 is formed on the sing...

Embodiment 2

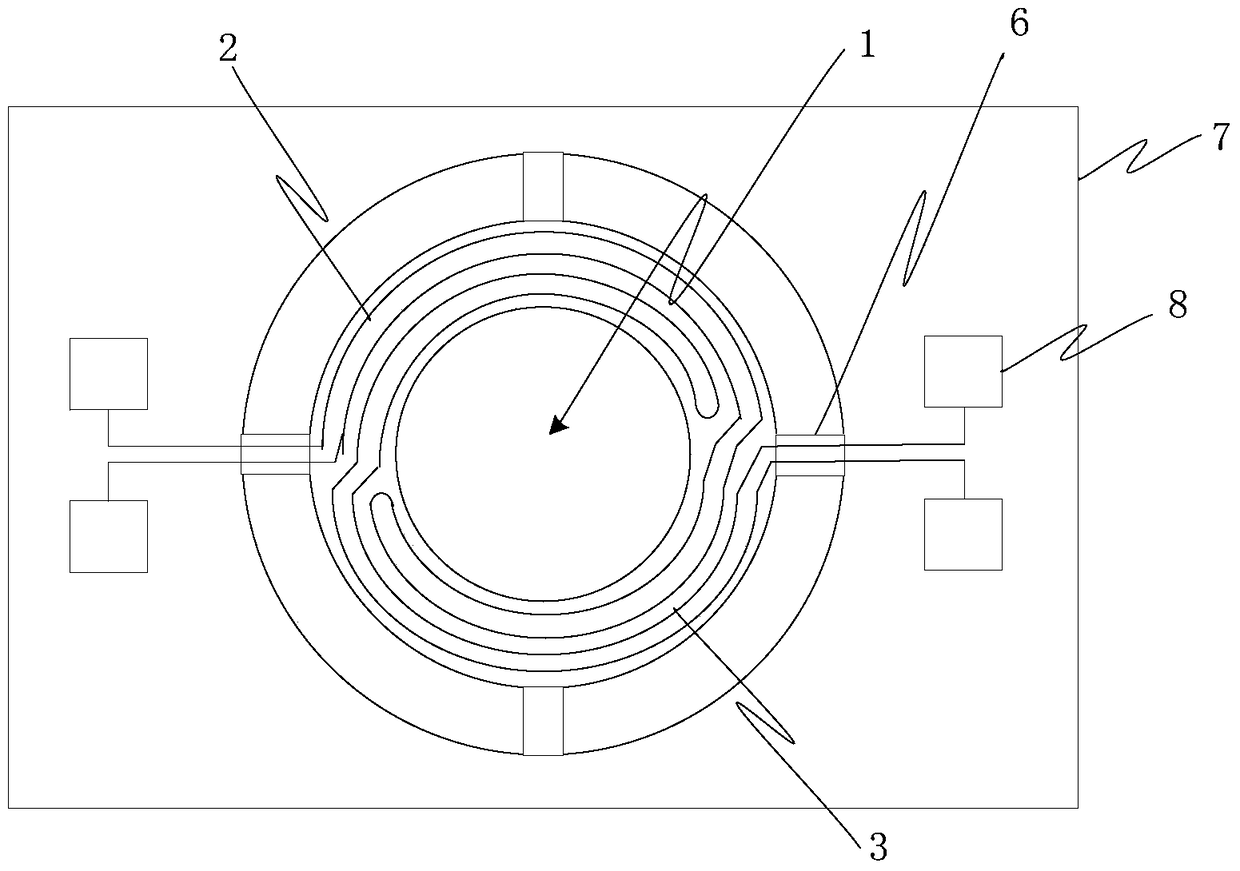

[0050] Such as figure 2 and Figure 4 ~ Figure 5 As shown, the present invention provides a MEMS thermo-optic tunable filter with low optical loss, and the MEMS thermo-optic tunable filter comprises a multi-cavity optical fiber whose half-wave resonant cavity adopts AlN or GaN thermo-optic tunable dielectric film material 11 The interference thin film filter layer 1 and the micro heater 2 can adjust the central wavelength of the MEMS thermo-optic tunable filter by controlling the operating current of the micro heater 2 .

[0051] Such as Figure 4 ~ Figure 5 As shown, when the multi-cavity optical interference thin film filter layer 1 has sufficient mechanical strength, the MEMS thermo-optic tunable filter in this embodiment includes: multi-cavity optical interference thin film filter layer 1, silicon Substrate 7 , light hole, micro heater 2 , micro temperature sensor 3 and lead pad 8 .

[0052] The multi-cavity optical interference film filter layer 1 is formed on a silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com