Sulfur-containing composite anode, preparation method thereof and lithium-sulfur battery using sulfur-containing composite anode as anode

A technology of composite positive electrode and conductive agent, applied in the direction of lithium battery, battery electrode, non-aqueous electrolyte battery, etc., can solve problems such as battery performance degradation, and achieve the effects of improving discharge voltage, simple preparation process, and improving the specific energy of first discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

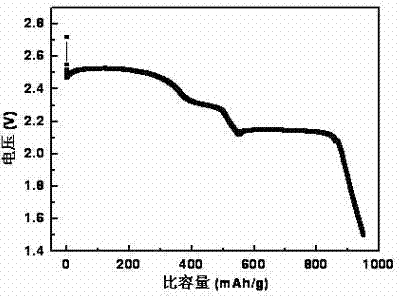

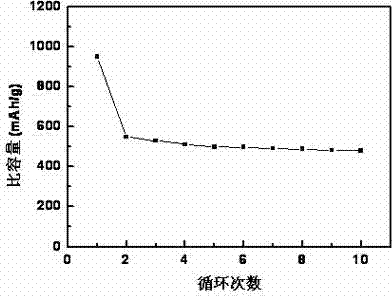

[0030] Active material preparation: Weigh the corresponding materials according to carbon fluoride: elemental sulfur = 50:50 (mass ratio), mix them initially and put them in a mortar for grinding and mixing to prepare active materials mixed with carbon fluoride additives.

[0031] Preparation of sulfur-containing composite positive electrode: Weigh 0.1g binder polyvinylidene fluoride (PVDF) and dissolve it in N-methylpyrrolidone (NMP), stir to form a uniform solution; weigh 0.2g conductive agent superconducting carbon black (Super P ) into the above binder solution, fully stirred to form a uniform conductive agent suspension; then add 0.7g of pre-mixed active material, fully stirred to form a stable slurry suspension. The slurry was coated on the corroded aluminum foil current collector with a doctor blade, and dried at 70° C. for 2 hours until the NMP volatilized completely. Active material in the pole piece after drying: conductive agent: binder = 70:20:10. The surface dens...

Embodiment 2

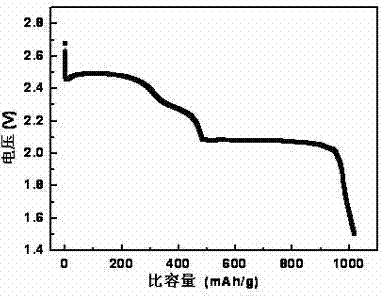

[0035] Active material preparation: Weigh the corresponding materials according to carbon fluoride: elemental sulfur = 40:60 (mass ratio), mix them initially and place them in a mortar for grinding and mixing to prepare active materials mixed with carbon fluoride additives.

[0036] Preparation of sulfur-containing composite positive electrode: Weigh 0.1g binder polyvinylidene fluoride (PVDF) and dissolve it in N-methylpyrrolidone (NMP), stir to form a uniform solution; weigh 0.2g conductive agent superconducting carbon black (Super P ) into the above binder solution, fully stirred to form a uniform suspension; then add 0.7g of pre-mixed active material, fully stirred to form a stable slurry suspension. The slurry was coated on the corroded aluminum foil current collector with a doctor blade, and dried at 70° C. for 2 hours until the NMP volatilized completely. Active material in the pole piece after drying: conductive agent: binder = 70:20:10. The surface density of the cont...

Embodiment 3

[0040] Active material preparation: Weigh the corresponding materials according to carbon fluoride: elemental sulfur = 35:65 (mass ratio), mix them initially and put them in a mortar for grinding and mixing to prepare active materials mixed with carbon fluoride additives.

[0041]Preparation of sulfur-containing composite positive electrode: Weigh 0.1g binder polyvinylidene fluoride (PVDF) and dissolve it in N-methylpyrrolidone (NMP), stir to form a uniform solution; weigh 0.2g conductive agent superconducting carbon black (Super P ) into the above binder solution, fully stirred to form a uniform suspension; then add 0.7g of pre-mixed active material, fully stirred to form a stable slurry suspension. The slurry was coated on the corroded aluminum foil current collector with a doctor blade, and dried at 70° C. for 2 hours until the NMP volatilized completely. Active material in the pole piece after drying: conductive agent: binder = 70:20:10. The surface density of the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com