Preparation method of carbon dioxide separation film based on graphene material

A gas separation membrane, carbon dioxide technology, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problems of poor stability, harsh operating conditions, poor repeatability, etc., to achieve a wide range of applications, simple process economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

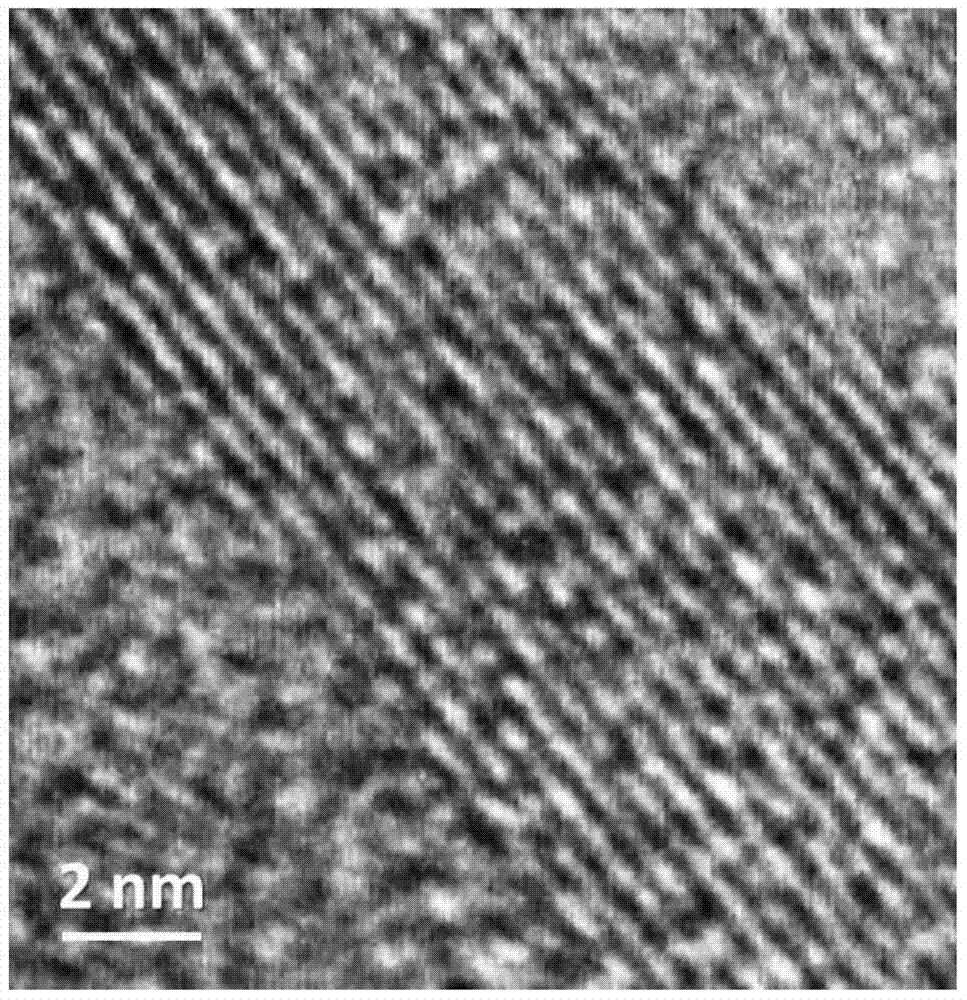

Image

Examples

Embodiment 1

[0020] 1) Weigh 0.1 g of carboxylated graphene and add it to 50 ml of deionized water, and stir and ultrasonically make the carboxylated graphene completely dispersed in the water.

[0021] 2) Add 4 g of polyethylene glycol into 80 g of ethanol, heat and stir at 70° C. for 6 hours, and leave the solution standing for use.

[0022] 3) Add the aqueous dispersion of carboxylated graphene in 1) to the polyethylene glycol solution in step 2), heat and stir at 70°C for 10 hours, then lower the temperature of the solution to 50°C and let stand for defoaming, A coating liquid is prepared.

[0023] 4) Coating the coating liquid in step 3) on the sheet-type Al with an average pore size of 20nm 2 o 3 One side of the support was dried naturally in the air, the curing temperature was 80° C., and the curing time was 24 hours to obtain a graphene-based gas separation membrane.

[0024] Determination of the composite membrane prepared in this example for CO 2 / N 2 , CO 2 / CH 4 and CO ...

Embodiment 2

[0026] 1) Weigh 0.15g of hydroxylated graphene and add it to 50ml of DMF, and stir and ultrasonically make the carboxylated graphene completely dispersed in DMF.

[0027] 2) Add 10 g of carboxymethyl cellulose into 40 g of toluene, heat and stir at 80° C. for 5 hours, and leave the solution standing for use.

[0028] 3) Add the DMF dispersion of hydroxylated graphene in 1) to the carboxymethyl cellulose solution in step 2), heat and stir at 90°C for 15 hours, then lower the temperature of the solution to 60°C and let stand for defoaming , to prepare a coating solution.

[0029] 4) Coating the coating liquid in step 3) on the sheet ZrO with an average pore size of 200nm 2 One side of the support was dried naturally in the air, the curing temperature was 90° C., and the curing time was 10 hours to obtain a graphene-based gas separation membrane.

[0030] Determination of the composite membrane prepared in this example for CO 2 / N 2 , CO 2 / CH 4 and CO 2 / H 2 Gas separati...

Embodiment 3

[0032] 1) Weigh 0.005g mercaptographene and add it into 50ml DMSO, and stir and ultrasonically make mercaptographene completely dispersed in DMSO.

[0033] 2) Add 3 g of sodium alginate into 30 g of xylene, heat and stir at 110° C. for 4 hours, and let the solution stand for use.

[0034] 3) Add the DMSO dispersion of mercaptographene in 1) to the sodium alginate solution in step 2), heat and stir at 85°C for 12 hours, then lower the temperature of the solution to 50°C for defoaming, and prepare Get coating solution.

[0035] 4) Coat the coating liquid in step 3) on one side of the tubular mullite support with an average pore diameter of 1000 nm, and let it dry naturally in the air, the curing temperature is 75° C., and the curing time is 15 hours. A gas separation membrane based on a graphene material is obtained.

[0036] Determination of the composite membrane prepared in this example for CO 2 / N 2 , CO 2 / CH 4 and CO 2 / H 2 Gas separation performance, when the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com