Rapid thermal cycle injection molding device based on graphene coating

An injection molding device and graphene technology, applied in the direction of coating, etc., can solve the problem of thermal uniformity of the contaminated cavity, and achieve the effects of improving the difficulty of peeling, enhancing fluidity, and improving heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

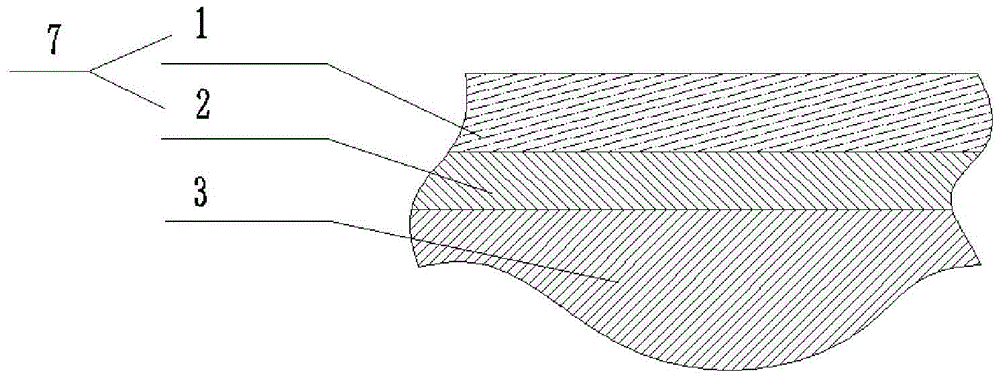

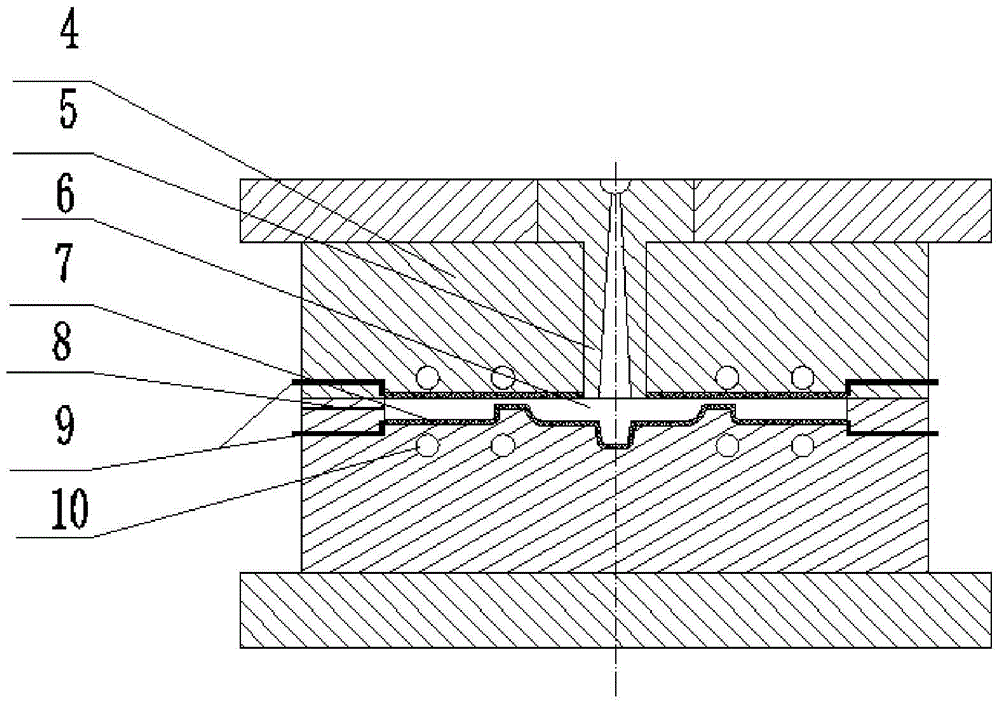

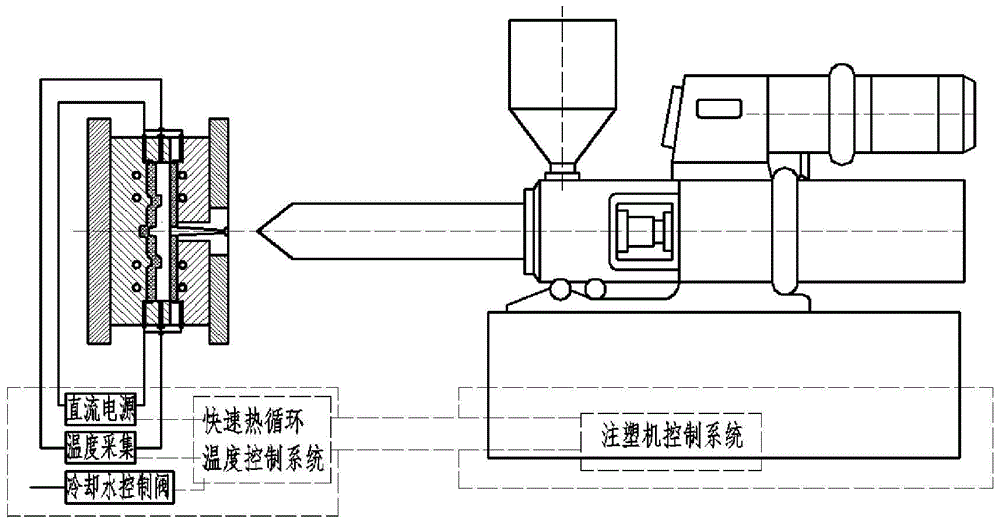

[0022] The invention is based on a graphene coating rapid thermal cycle injection molding device, which includes a polymer plasticizing injection device, a mold clamping device, a mold and a frame. The polymer plasticizing injection device and the mold clamping device are fixed on the frame, and the mold is installed on the mold clamping device. Between the templates of the device, the polymer plasticizing injection device injects the polymer melt into the mold, and the clamping device controls the opening and closing of the mold. The coating rapid thermal cycle device includes a silicon-based graphene coating, a DC power supply, a cooling water pipeline, a thermocouple and a temperature control system device; the silicon-based graphene coating is distributed on the surface of the mold cavity; the DC power supply passes through the copper electrode and the graphene coating. The two ends are connected to form a power loop; the thermocouple is distributed near the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com