Normal temperature liquid phase adsorption and membrane separation dehydration method for polyoxymethylene dimethyl ether

A technology of polyoxymethylene dimethyl ether and liquid phase adsorption, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve the difficulty of rectification and separation, the increase of investment cost, energy consumption and operating cost and other issues to achieve the effect of ensuring complete independent operation, ensuring continuity, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for normal temperature liquid phase adsorption and membrane separation and dehydration of polyoxymethylene dimethyl ether described in this embodiment comprises the following steps:

[0043] (a) At room temperature, send the polyoxymethylene dimethyl ether to be dehydrated into an adsorption tower equipped with an adsorbent for adsorption treatment, and the adsorbed polyoxymethylene dimethyl ether is discharged from the adsorption tower and enters the product In the collection tank, the adsorbent here can be one, two or more of molecular sieves, silica gel, activated alumina, and resins, which can be determined according to needs;

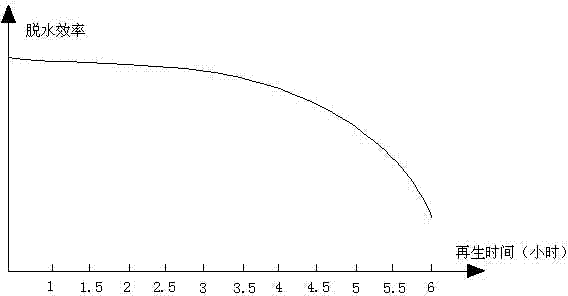

[0044] (b) When the adsorbent reaches saturation, the adsorption value at this time is not necessarily the maximum adsorption value, but the adsorption effect of the adsorbent on water at this time cannot make the water content of polyoxymethylene dimethyl ether meet the requirements. Critical value, stop feeding at this time, and r...

Embodiment 2

[0067] like Figure 4 As shown, the present embodiment takes two adsorption towers as an example to introduce the whole dehydration process of polyoxymethylene dimethyl ether. Among the figures, A, B, C, D, T, a, b, c, t, and d are all valve;

[0068] (1) Open the valves T, A, and D, and send the polyoxyl dimethyl ether with a water content of 0.8% into the adsorption tower 1 through the pump 1, and the polyoxyl dimethyl ether is adsorbed in the adsorption tower 1 for 8 hours. The polyoxymethylene dimethyl ether after adsorption enters in the product collection tank from the top of adsorption tower one;

[0069] (2) Close valves A and D of adsorption tower one, open valves B, a, t and d, discharge the residual polyoxymethylene dimethyl ether and water in adsorption tower one, and at the same time pump the raw material polyoxymethylene dimethyl ether through pump one The base dimethyl ether is sent to the second adsorption tower for dehydration;

[0070] (3) After the adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com