Preparation method for progesterone intermediate

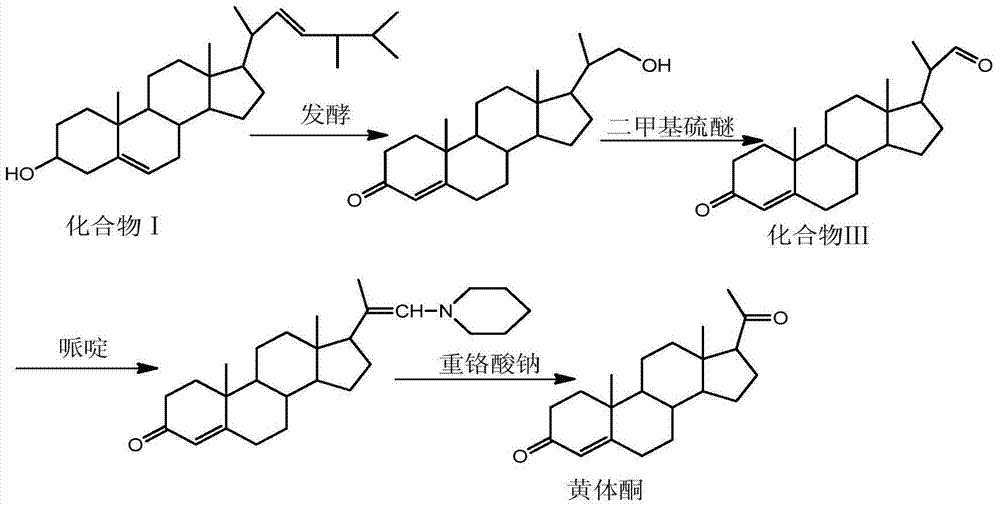

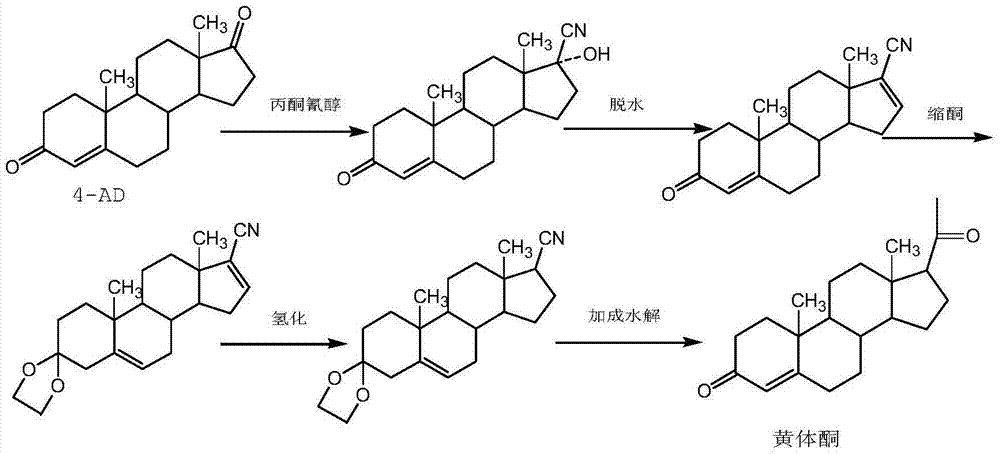

A technology for intermediates and progesterone, which is applied in the field of preparation of progesterone intermediates, can solve problems such as long production routes, and achieve the effects of short synthesis time, high purity and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

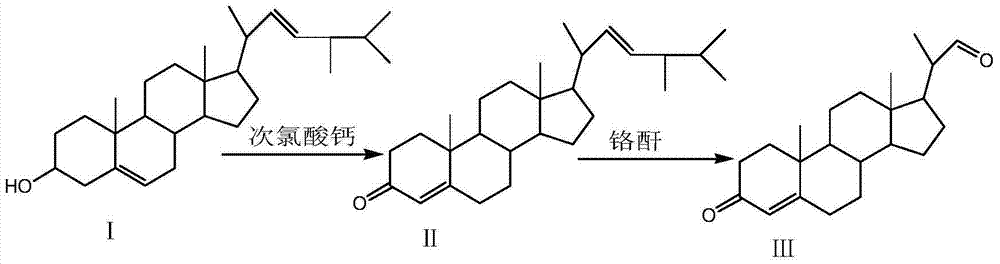

[0033] (1) Calcium hypochlorite oxidation

[0034] Accurately measure 80ml of ethyl acetate into a three-necked reaction flask, add 10g of compound I under stirring, stir until the material is dissolved, add calcium hypochlorite oxidant, control the temperature to 20 °C for reaction, react for 3h, TLC point plate until the reaction of the raw materials is complete, add 1.8 g of sodium bisulfite was stirred for 15 min to terminate the reaction. The reaction solution was transferred to a separatory funnel, left to stand for layers, and the ethyl acetate layer was washed with drinking water until neutral. Concentrate ethyl acetate to dryness, obtain 9g compound II; Described calcium hypochlorite oxidant is: calcium hypochlorite, sodium bromide, the mixture of water, wherein the ratio of the mass of each component to compound I is: 0.26: 0.015:3:1.

[0035] (2) chromic anhydride oxidation

[0036] Add 9g of compound II into a reaction flask containing 5.4ml of glacial acetic ac...

Embodiment 2

[0038] (1) Calcium hypochlorite oxidation

[0039] Accurately weigh 200ml of ethyl acetate into a three-necked reaction flask, add 20g of compound I under stirring, stir until the material dissolves, add calcium hypochlorite oxidant, control the temperature to 30 °C for reaction, react for 2h, TLC point plate until the reaction of the raw materials is complete, add 4 g of sodium bisulfite was stirred for 15 min to terminate the reaction. The reaction solution was transferred to a separatory funnel, left to stand for layers, and the ethyl acetate layer was washed with drinking water until neutral. Concentrate ethyl acetate to dryness to obtain 18.2g of compound II; the calcium hypochlorite oxidant is: a mixture of calcium hypochlorite, sodium bromide and water, wherein the ratio of the mass of each component to compound I is: 0.3 :0.012:2:1. (2) chromic anhydride oxidation

[0040] Add 18.2g of compound II into a reaction flask containing a certain amount of 14.6ml of glacia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com