Parallel type double-flow variable-speed drive device

A transmission device and variable speed transmission technology, which is applied in the field of vehicle transmission system, can solve problems such as few mechanical transmission parts, difficulty in meeting user needs, and unsuitable high working speed of hydraulic motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Embodiment: A parallel double-flow transmission device suitable for vehicles, which has four forward gears including neutral gear, I gear to IV gear, and one reverse gear.

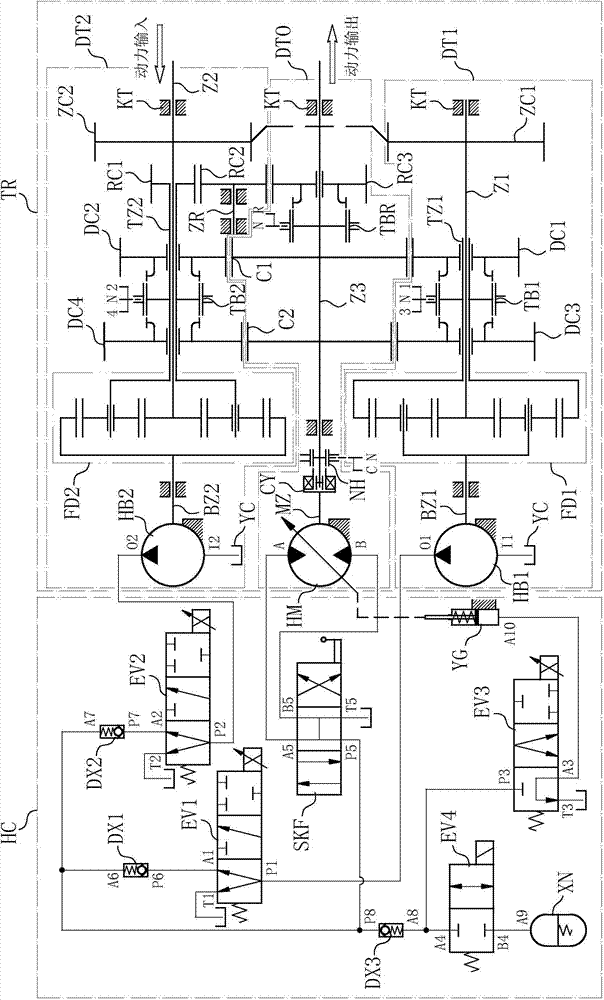

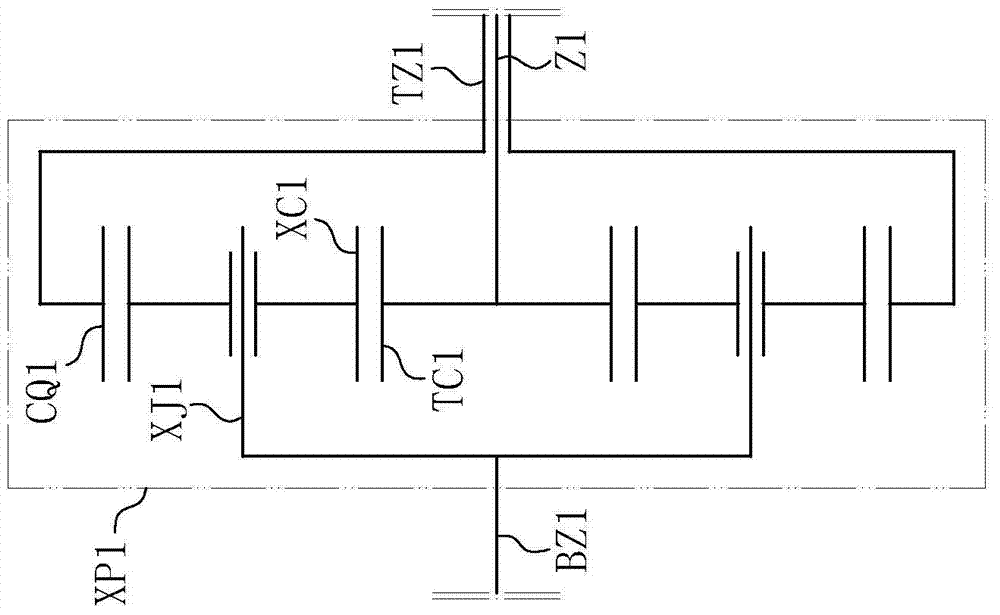

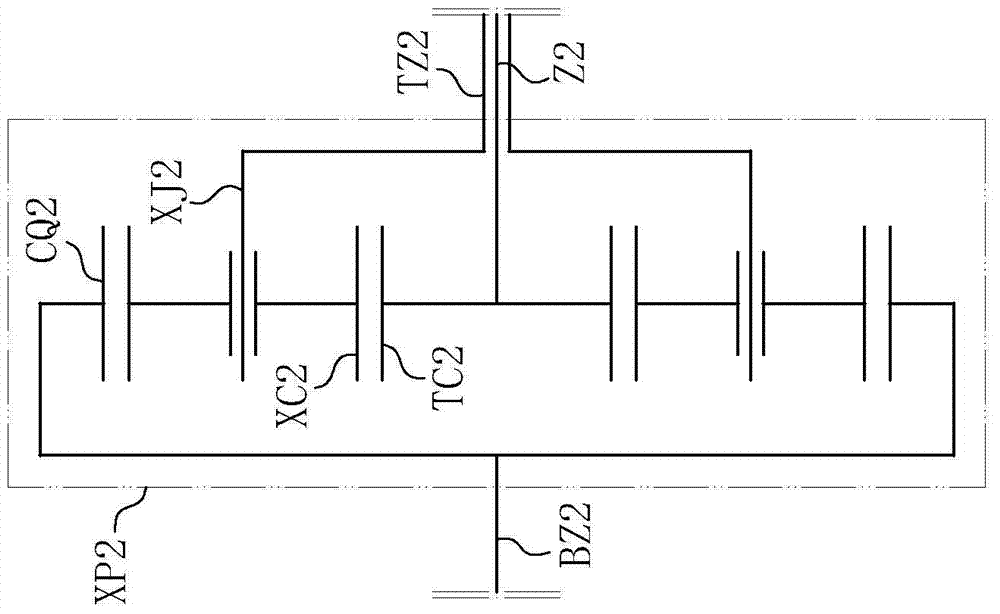

[0051] see figure 1 , figure 2 and image 3 , the parallel double-flow variable speed transmission device is composed of a variable speed transmission system TR, a hydraulic control system HC, an oil tank YC and a device housing KT. Wherein, the variable speed transmission system TR is composed of a first power input variable speed transmission unit DT1, a second power input variable speed transmission unit DT2 and a power output unit DTO.

[0052] The first power input variable speed transmission unit DT1 includes the first transfer case FD1, the first shaft Z1, the first sleeve shaft TZ1, the main drive driven gear ZC1, the first gear driving gear DC1, the third gear driving gear DC3, and the first gear. - III gear synchronizer TB1, first pump shaft BZ1, first hydraulic pump HB1.

[0053] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com