Qualitative and quantitative analysis method for old negative plate of lead acid battery

A quantitative analysis, lead-acid battery technology, applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of unknown phase analysis test, unclean removal of sulfuric acid on the surface, inaccurate test results, etc., to achieve accurate and rapid qualitative and quantitative analysis , Low test cost and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Configuration of boric acid-salicylic acid impregnating solution:

[0022] (1) According to the mass ratio of boric acid to deionized water is 1:8~10, first add deionized water into the container and heat it to 60~80°C, then add boric acid into deionized water and stir slowly until completely dissolved to obtain boric acid solution ,stand-by;

[0023] (2) According to the mass ratio of salicylic acid and alcohol as 1:3~4, add salicylic acid into alcohol and stir slowly until completely dissolved to obtain salicylic acid alcohol solution;

[0024] (3) According to the mass ratio of salicylic acid alcohol solution and boric acid solution at 1:4~6, add salicylic acid alcohol solution into boric acid solution at a temperature of 60°C~70°C, and stir until the two are evenly mixed to obtain boric acid - Salicylic acid impregnation solution, keep the temperature of the impregnation solution at 60°C to 80°C.

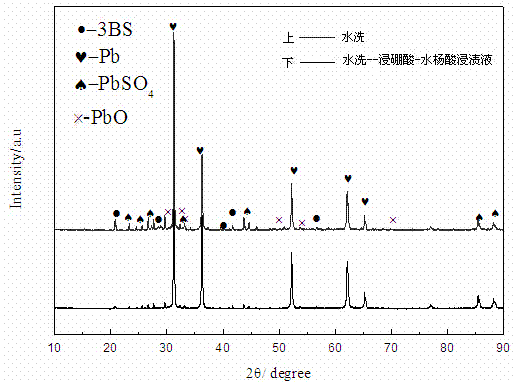

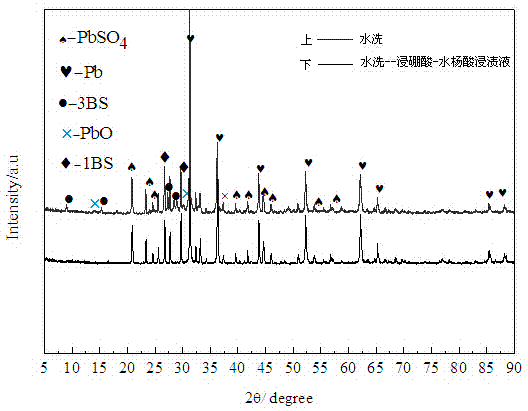

[0025] 2. Determination of the composition of the negative plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com