Multi-core anti-irradiation optical cable and its manufacturing process

A radiation-resistant and optical cable technology, applied in the direction of light guides, optics, optical components, etc., can solve problems such as poor bending resistance and optical transmission performance, large outer diameter of multi-core radiation-resistant optical cables, and poor consistency of multi-fiber transmission. Engineering application, meeting the special environmental requirements of aerospace, good effects of bending resistance and light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below, and the characteristics and principles of the multi-core radiation-resistant optical cable will be described in detail.

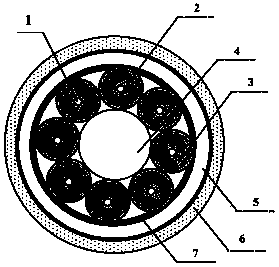

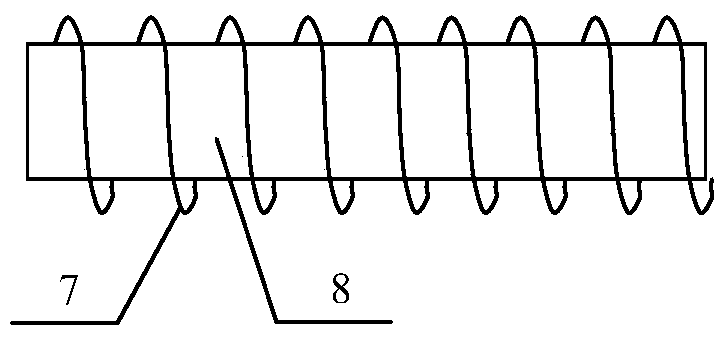

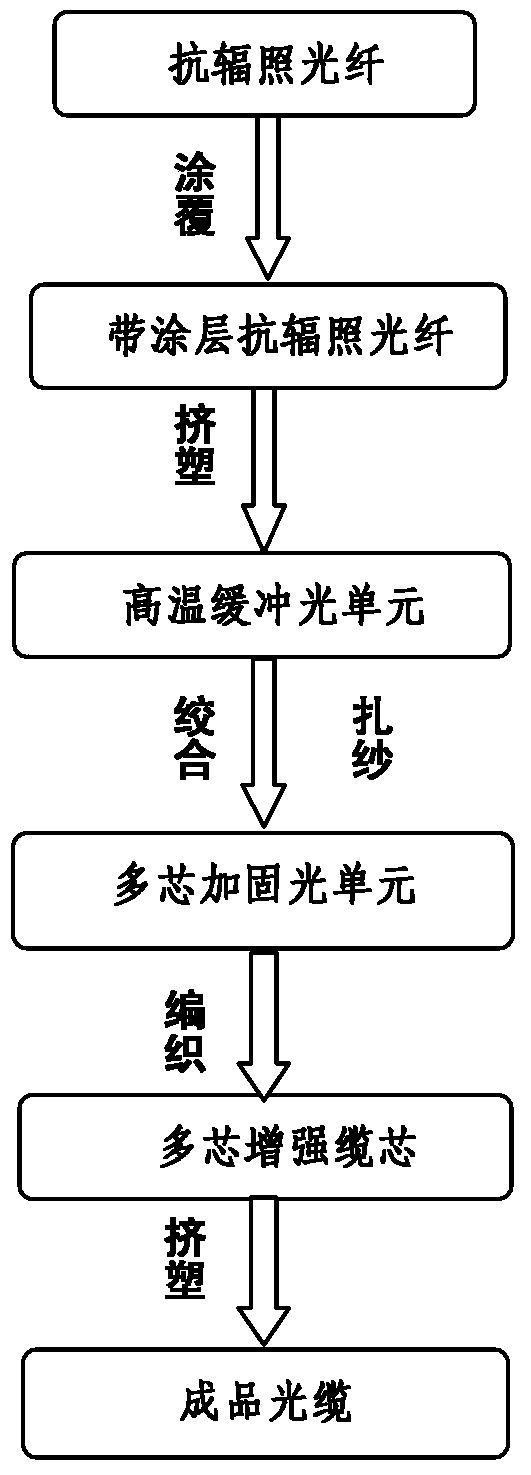

[0028] The structure of the multi-core radiation-resistant optical cable in this embodiment is schematically shown as figure 1 As shown, the radiation-resistant optical fiber 1 is coated with a high and low temperature resistant coating 2, and covered with a buffer layer 3 to form an optical unit; the multi-core twisted optical unit 8 is composed of 8 optical units that are twisted in a certain way by the multi-core twisted optical unit The pitch is wound on the filler core 4. The structure diagram of the multi-core hardened optical unit is as follows: figure 2 As shown, a single fine-denier yarn 7 is helically wound at a certain pitch on the outside of the multi-core stranded optical unit 8 to form a multi-core reinforced optical uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com