Fly-ash-based carbon dioxide curing agent and preparation method thereof

A technology of carbon dioxide and fly ash, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve the effect of increasing porosity, wide sources, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

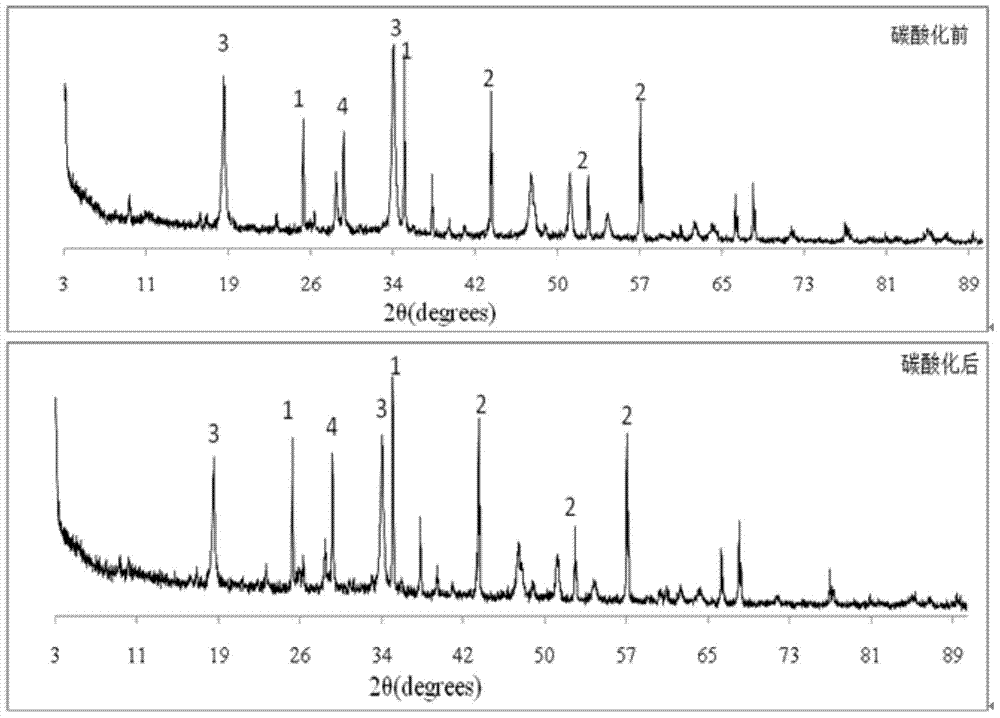

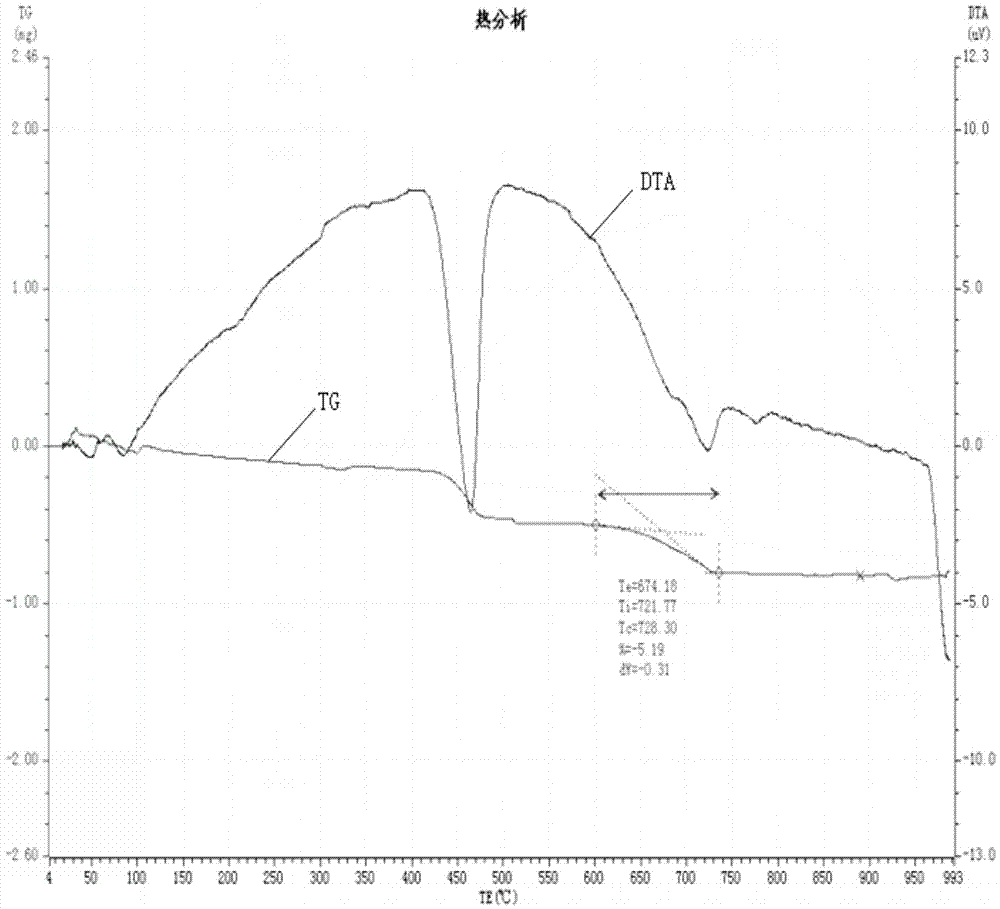

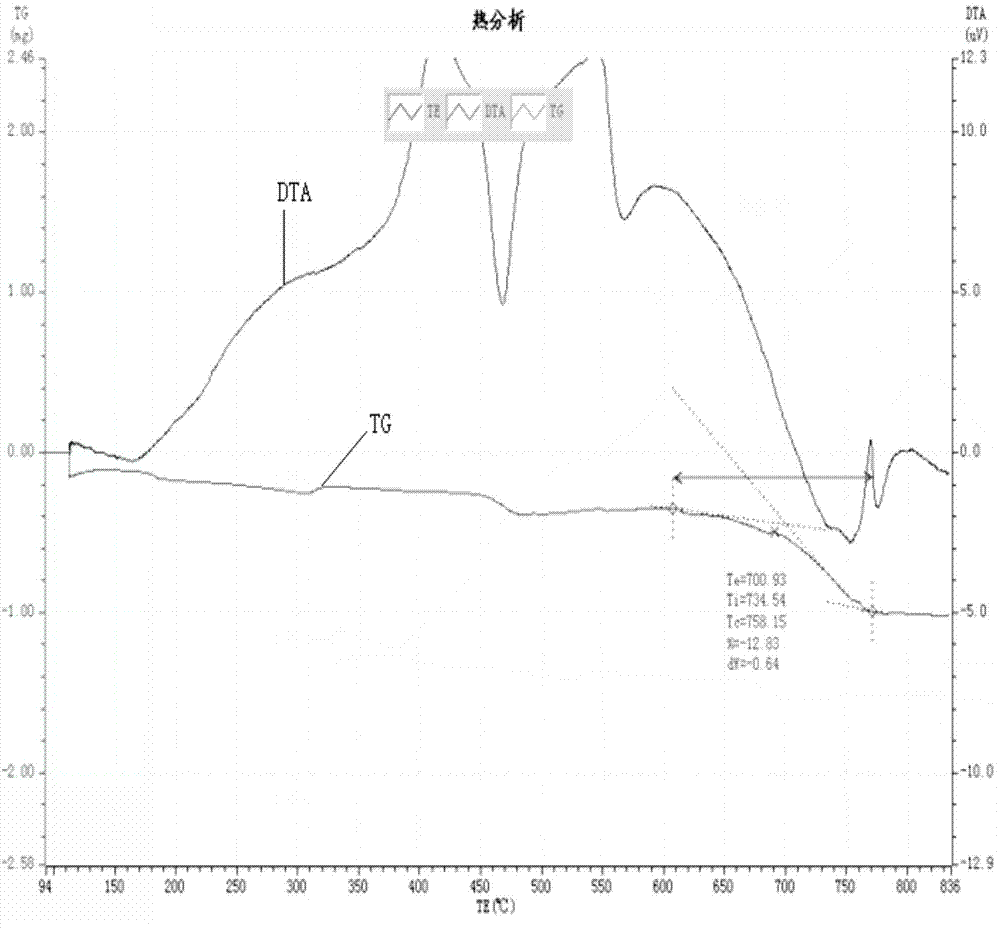

[0044] Weigh 300g of fly ash and slaked lime and 200g of alumina in a 1L beaker in a ratio of 1:1, add appropriate amount of water, and stir with a glass rod to make it fully mixed. Then use a magnetic stirrer to fully stir for 3h. Take it out and dry it at 105°C. As for the firing in the muffle furnace at 300°C for 1 hour. Take it out and cool it, store it in a sealed bag, and affix the label to obtain the fly ash-based carbon dioxide curing agent. The changes in the chemical composition of the fly ash-based carbon dioxide curing agent before and after the carbon capture reaction are shown in Table 1. The image changes before and after the carbon capture reaction, the thermogravimetric-differential thermal changes before and after the carbon capture reaction, and the microscopic morphology changes before and after the carbon capture reaction. see figure 1 , diagram 2-1 , 2-2 with Figure 3-1 , 3-2 .

[0045] Table 1 Changes in chemical composition of the fly ash-based carbon...

Embodiment 2

[0055] Weigh 400g and 200g of fly ash and slaked lime and 200g of alumina in a 1L beaker in a ratio of 2:1, add appropriate amount of water, and stir with a glass rod to make it fully mixed. Then use a magnetic stirrer to fully stir for 3h. Take it out and dry it at 105°C. As for the firing in the muffle furnace at 300°C for 1 hour. Take it out and cool it, store it in a sealed bag, and affix the label to obtain the fly ash-based carbon dioxide curing agent.

Embodiment 3

[0057] Weigh 450g and 150g of fly ash and slaked lime and 200g of alumina in a 1L beaker in a ratio of 3:1, add appropriate amount of water, and stir with a glass rod to make it fully mixed. Then use a magnetic stirrer to fully stir for 3h. Take it out and dry it at 105°C. As for the firing in the muffle furnace at 300°C for 1 hour. Take it out and cool it, store it in a sealed bag, and affix the label to obtain the fly ash-based carbon dioxide curing agent.

[0058] Fly ash is a bulk waste of coal mines with a wide range of sources and low cost. It has a high specific surface area, and the fly ash contains alkali metal oxides such as CaO, and it has the ability to adsorb and fix CO by carbonation. 2 It can be used as a large amount of material in the preparation of curing agent. At the same time, slaked lime is used to improve the content of alkaline earth metals in fly ash, and the addition of alumina can effectively increase the porosity of the material. The high porosity wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com